Site Search

Search within product

"Development and marketing of environmentally friendly coated fertilizers."

2023.12.25

environmentJCAM Agri Co., Ltd. is a leading manufacturer and distributor of fertilizers and other agricultural materials in Japan.

We are committed to the sustainable development of agriculture, which supports the food of the

Recently, certain results have been achieved in the development of environmentally friendly coated fertilizers, and research has been conducted to develop a new type of fertilizer that is environmentally friendly.

We would like to inform you of the development status and sales schedule.

Coated fertilizers are used in rice paddies and fields by coating the surface of fertilizer granules with resin (plastic) or other material.

This fertilizer was developed to control the leaching of fertilizer components at the initial fertilizer leaching.

The fertilizer is supplied to the crop when it needs it, because the fertilizer is suppressed and the fertilizer effect can be maintained for a long time.

The company is able to supply the product.

As a result, crops can absorb fertilizer more efficiently, reducing the amount of fertilizer applied and reducing the runoff of fertilizer components.

The product has contributed to environmentally friendly fertilizer application by reducing the environmental impact of fertilizers through volatilization and volatilization.

JCM Agri Co., Ltd. is developing a new coated fertilizer that contributes to sustainable agricultural production.

We have been working on the development of J-Coat®, a coated fertilizer to reduce plasticity, and we are planning to sell it.

We will do so.

Also, about coated fertilizers using biodegradable resins with a film that can be degraded in the natural environment,

We are pleased to report that we have obtained a development product that has the same elution inhibitory function as some commercial brands.

JA Zen-Noh continues to promote the new "J-Coat® " and the development of coated fertilizers using biodegradable resins and other materials.

We will continue to promote this project with the cooperation of related organizations such as

1. development and marketing of coated fertilizers with reduced plastic use

The amount of plastic contained in the film has been reduced to the same level as conventional products ("LP Coat®" and "M Coat®").

We have developed "J-Coat®", which has a similar elution inhibiting function and high film shell disintegrating property. This

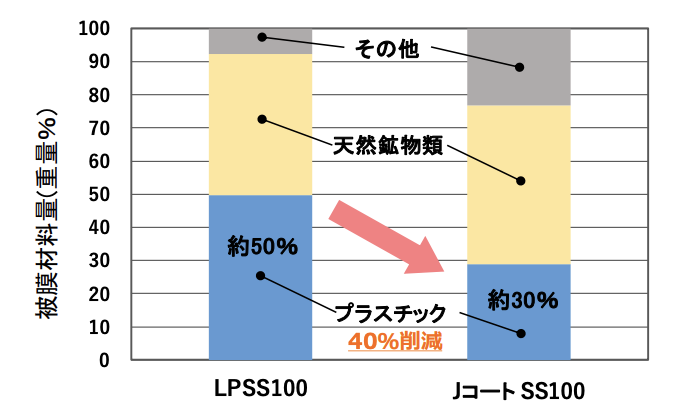

The development of a new "J-Coat®," which reduces the amount of plastic used in conventional products by 40%, has recently been completed,

The sales schedule has been finalized.

Conventional coatings contain about 50% plastics along with natural minerals (fertilizers).

(about 5% per grain), while the new "J-Coat®" reduces the amount of plastic in the coating to about 30%.

(about 3% per fertilizer grain).

In addition, the shells are more collapsible than conventional shells and are less likely to rise to the surface of the water, making them suitable for use in paddy fields.

The runoff from the paddy field can be controlled. In addition, runoff prevention measures (shallow-water plowing, natural water fall-off, and paddy runoff outlet necks) can be taken.

(e.g., by installing a waterproofing system) can be combined to prevent runoff into rivers and oceans.

Currently, we are building a system to increase production of new "J-Coat®" and expect to produce the main brand in 2024.

The market is scheduled to be launched within the next three months.

2. development of coated fertilizers with biodegradable resin

The coated fertilizers use biodegradable resin for the film, and the film shell can be decomposed in the natural environment after the fertilizer has been eluted.

Development is underway. We have recently developed a new fertilizer brand for some of our coated fertilizers in the laboratory.

We are pleased to report that we were able to develop a coated fertilizer with a leaching inhibitory function similar to that of conventional products.

The developed product is a 100-day, linear type, and other short- and long-term types or sigmoidal types are available.

The "D" type is currently under development. We will continue to conduct research and expand the range of brands and types, aiming for widespread use by 2030.

We are working on development with the aim of