Site Search

Search within product

第732号 2021 (R03) .07発行

Click here for PDF version

農業と科学 令和3年7月

本号の内容

§被覆肥料「Jコート」の水稲に対する全量基肥施用の効果と被膜崩壊性

Agriculture and Forestry Department, Kita-Akita Regional Development Bureau, Akita Prefecture

主査 松田 英樹

(Former affiliation: Akita Prefectural Agricultural Experiment Station)

§土のはなし−第3回

よい土の条件 物理的性質−その2

土の硬さはどのようにしてきまるのか

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

J-Coat" coated fertilizer on paddy rice

全量基肥施用の効果と被膜崩壊性

Agriculture and Forestry Department, Kita-Akita Regional Development Bureau, Akita Prefecture

主査 松田 英樹

(Former affiliation: Akita Prefectural Agricultural Experiment Station)

Introduction

被覆肥料は,尿素等を樹脂や硫黄でコーティングした肥料であり,窒素の溶出をコントロールすることができることから,作物の生育に合わせた養分供給や肥料成分の利用率の向上,肥料の施用回数の削減による省力化を可能にする機能的な肥料として多くの作物生産に用いられている1)。一方,被覆肥料の被膜は自然環境で生分解性や光分解性があるものの全ての被膜の分解には時間を要するため,水稲作では肥料成分が溶出した後,残った被膜が代かき水とともに水系に流出することが懸念されている。そのため,被膜の系外流出の防止に向けた生産者への注意喚起に加え,自然環境下での被膜の分解性の向上や使用する樹脂量の削減などの技術開発をより一層進める必要がある2)The following is a list of the most common problems with the "C" in the "C" column.

このような背景を受け,近年,被膜の系外流出の抑制に寄与すると期待される被膜崩壊性の高い被覆肥料「Jコート」が新たに開発された。本研究では,2019年と2020年に「Jコート」の窒素溶出パターンや水稲の生育及び収量に及ぼす影響,水稲1作後の被膜崩壊率を明らかにしたので報告する。

2. Methods

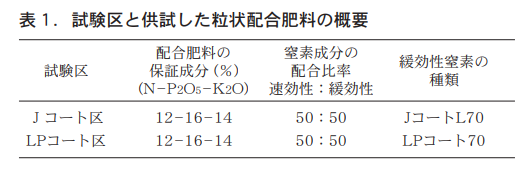

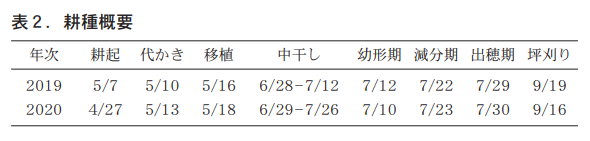

試験は秋田県農業試験場(秋田県秋田市雄和相川)の水田ほ場(土壌条件;グライ低地土(幡野統))で行った。供試品種は「あきたこまち」とした。試験区はJコート区及びLPコート区を各3連設置し,水稲の栽培試験に供試した肥料は,JコートL70及びLPコート70を含む粒状配合肥料である(表1) 。2019年は耕起前の5月6日に,2020年は耕起後代かき前の5月11日に10kgN/10aを全層施肥した。栽植密度は2019年が21.3株/㎡,2020年が22.3株/㎡であった。耕種概要は表2のとおりである。

窒素溶出率は,肥料原体1gを入れた不織布を施肥日にほ場の地表面に静置し,耕起,代かき及び移植時を除いて田面から5cmの深さに埋設(2019年5連,2020年3連)した。

ほ場の地温は,施肥から坪刈りまで温度記録計(商品名:おんどとりTR-71wf型,(株)T&D製)で5cm深を1時間間隔で測定した。

The film collapse rate of the coated fertilizers was investigated using the JCAM method, in which mesh bags containing 100 g of the fertilizer (J-Coat L70 and LP-Coat 70) in 2019 and 50 g in 2020 were buried 5 cm below the rice surface in a row of three, then dug out about 6 months and 11 months after one rice crop, washed and dried, and then evaluated by applying external pressure to the test fertilizer. After washing and drying, the film collapse rate was evaluated by applying external pressure to the test sample fertilizer. The external pressure here was assumed to be the pressure applied at the time of plowing in the year following fertilizer application.

3. results

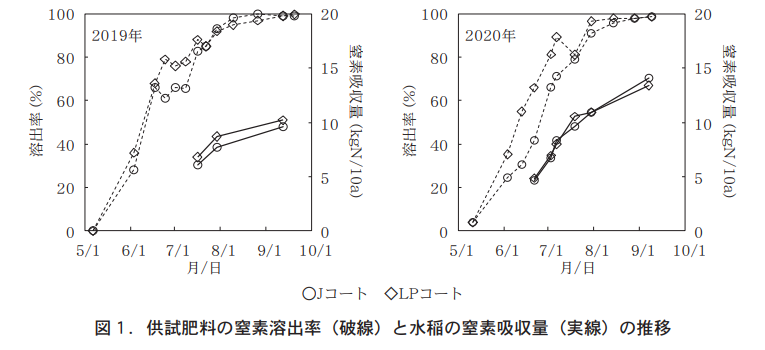

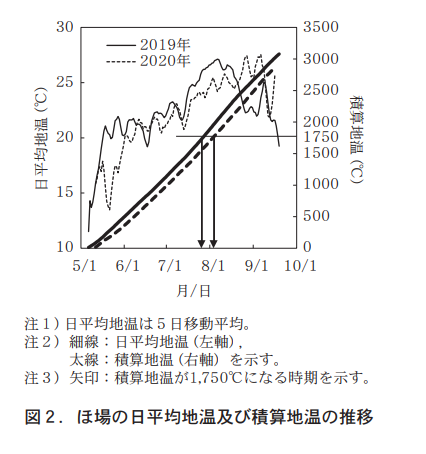

JコートL70の窒素溶出のスピードは,2カ年ともLPコート70よりも遅い傾向にあった。窒素溶出率が80%以上となったのは,LPコート70では2カ年とも7月上旬であったのに対して,JコートL70では2019年は7月中旬,2020年は7月下旬であった(図1)。ほ場の日平均地温に基づき推測される溶出率が80%となる時期(日平均地温が積算で1,750℃となる時期)は,いずれの供試肥料とも2019年では7月下旬,2020年では8月上旬となったため,両年の窒素溶出は早い傾向にあった(図2)。

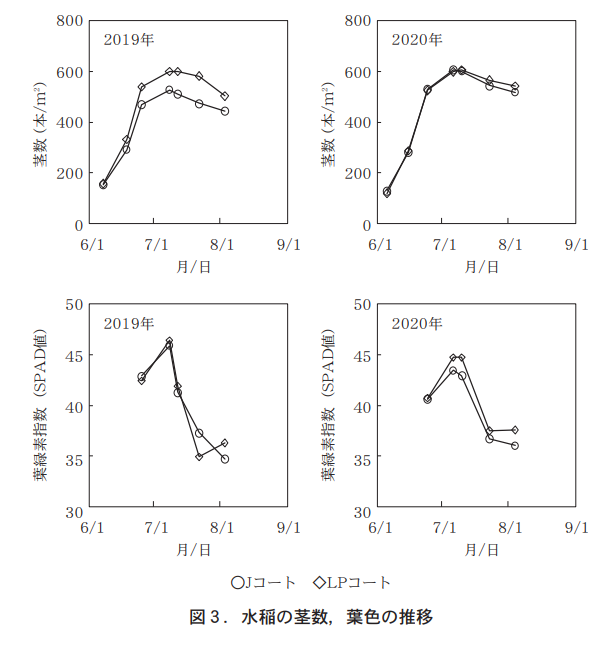

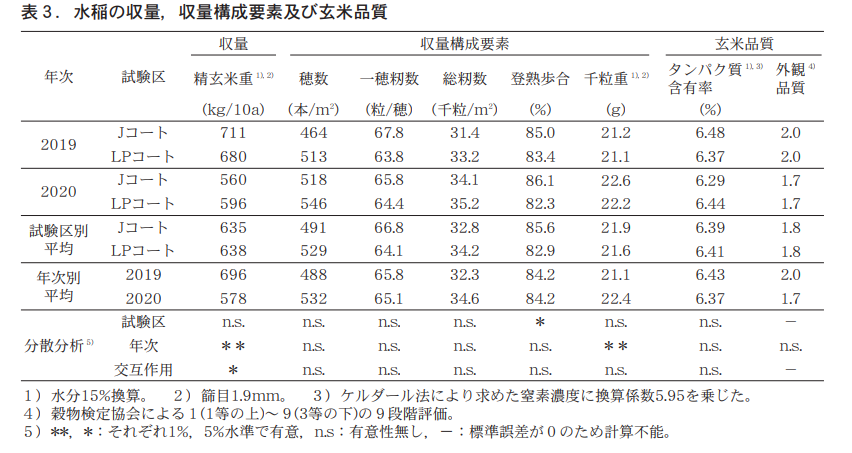

水稲の窒素吸収量についてJコート区とLPコート区を比較すると,2019年はJコート区で低く推移し,2020年は同等に推移した(図1)。Jコート区の生育は,2019年の場合,LPコート区よりも6月以降茎数が少なく推移し,2020年の場合,葉色が低く推移した(図3)。これはJコートL70の窒素溶出のスピードがLPコートよりも遅かったことが影響したと考えられた。収量,収量構成要素及び玄米品質についてJコート区とLPコート区を比較すると,2カ年とも統計的に有意な差はなく同等であった(表3)。

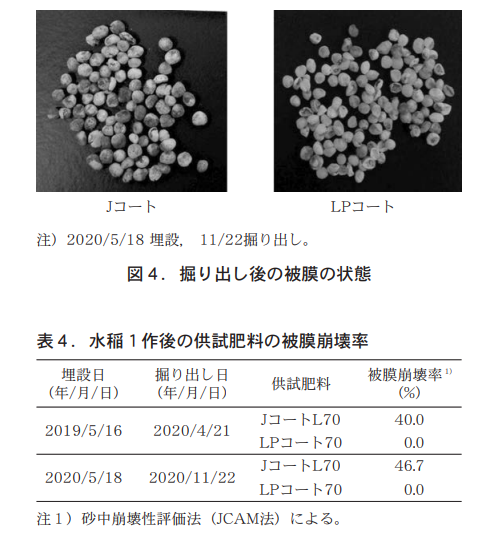

水稲1作後の供試肥料の被膜崩壊性について,外観ではいずれも明瞭ではないものの(図4),被膜に外圧を加えて評価する砂中崩壊性評価法(JCAM法)によると,水稲1作後の被膜の崩壊はLPコートでは認められなかったのに対して,Jコートでは4割程度の崩壊が認められた(表4)。

Summary

The effect of full basal application of J-Coat, a newly developed coated fertilizer with an easily collapsible film, on paddy rice plants and its film collapsibility were investigated. The results showed that nitrogen release of J-Coat L70 tended to be slower than that of LP-Coat 70, but the yields were similar. The film collapse rate after one crop of paddy rice was higher than that of LP Coat, indicating that J-Coat L70 contributes to preventing the film from leaching out of the system.

However, the results of this study were obtained when all layers were applied in the middle of May. In Akita Prefecture, side-row application of fertilizer at the time of transplanting is widely used, and it is assumed that the timing of application may be in late May. In addition, although the film collapse rate of J-coat was higher than that of LP-coat, it was about 40% after one crop of paddy rice. Further studies on the relationship between the burial period and the film collapse rate, and on the amount of film loss on a field scale, are needed to control the outflow of the film from the system.

References

1)上野正夫.肥効調節型肥料(被覆肥料)を用いた実用的普及技術.

農業と科学.p.6−11(2017)

2)日本肥料アンモニア協会,全国複合肥料工業会.

海洋漂着プラスチックを巡る肥料業界の対応について(2019)

土のはなし−第3回

よい土の条件 物理的性質−その2

How is soil hardness determined?

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Last month, we discussed soil thickness in terms of "soil thickness and hardness," one of the four conditions for good soil for crop production, which is related to the physical properties of soil. This month, we will focus on soil hardness.

1. what determines soil hardness

Some soil is so hard that it cannot be dug with a shovel, while others can be dug with ease.

What determines soil hardness? Basically, the size of "soil grains" (called grain size) determines soil hardness. Grains of soil? Some people may wonder why soil is hard. But think of sand and clay. Sand is rough and you can see each grain with your eyes. However, clay grains cannot be seen with the eyes and can only be seen in clumps.

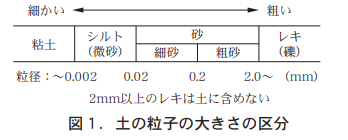

When the organic matter contained in the soil is completely removed and only the soil particles are left, the soil is composed of three types of particles: sand (classified into two types: coarse sand and fine sand), clay (clay here does not refer to clay used for clay works but to the very fine soil particles shown in Figure 1), and silt (fine sand), which is intermediate in size between the two. The problem is how much proportion these three types of particles have. The question is what proportion of these three types of particles make up the soil.

2. the finer the soil grains, the harder the soil.

If a glass bead is packed in a certain container, the smaller the bead is, the more space it has. If the glass beads are large, they cannot be packed without gaps, and many spaces are created. The term "denseness" is used to describe how many particles are packed in a certain volume. The degree of density becomes larger when it is packed with a small glass ball than when it is packed with a large glass ball. Clay has the finest grains, so clayey soil has a high degree of density. On the other hand, sand has coarse grains, so sandy soil has a small degree of density. Therefore, clayey soil is tightly packed into a certain volume and becomes hard soil. Sandy soil with coarse particles does not often produce soil as hard as clayey soil.

3. how is soil grain size determined?

Then, how is the size of soil grains determined? If soil grain size is innately determined, there would be no difference between sticky soil and sandy soil. Soil grain size is related to the way soil is formed.

土の原料は基本的に岩石(母岩)である(火山灰に由来する黒ボク土などは例外)。その岩石が風化作用で細かく砕かれていく。その細かく砕かれた岩石を土の母材という。土を構成する粒子の大きさは,原料となる岩石の質と,風化作用の影響程度で決まる。風化作用の時間を長く経験したり,岩石がもろくて風化作用をうけやすかったりすると,土は細かい粒子,すなわち粘土やシルトといった粒子が多くなる。その結果,細粒質の土ができる。この逆が砂質(粗粒質)の土である。その中間の状態が中粒質の土である。

4. very long time is needed to change the hardness of the soil

The hardness of soil is due to the finer and denser particles of soil. The soil particles contain the time it took for the rocks to break up and for the soil to be formed by the action of living organisms. Thus, it takes a daunting, very long-term effort to essentially soften the hardness of the soil.

For example, by feeding coarse organic matter, such as compost, to the soil over many generations, a cushion of organic matter is created in the soil, which gradually softens the soil. In addition, one might think that mixing in sand or other materials would be a good idea. Of course, this is theoretically possible. It may be possible in a small area such as a home garden. However, in a large field, sand must be nearby in large quantities. Sand from the coast is not suitable because of its salinity. It must be river sand. Considering these factors, bringing sand into a fine-grained soil is a picture-perfect and unrealistic idea. It is impossible to change clayey soil into sandy soil.

5. soil hardness is not determined by soil particles alone

So far, for the sake of simplicity, I have explained soil hardness only in terms of soil particles. However, soil hardness is not that simple. For example, soil hardness varies depending on the moisture content in the same soil. This can be seen from the fact that clay soil becomes hard and hard when it is dried. If such soil is gradually moistened with water, it becomes softer and softer, and finally liquefies into a sludge, which is outside the concept of hardness.

The nature of soil hardness is very complex, even when we speak of soil hardness in a nutshell. Here we are simplifying the story.

6. hardness is not the only thing that affects root elongation

Last month and this month we discussed the issue of soil thickness and hardness. This is because we wanted to consider the thickness of the effective soil layer in which roots can grow. However, whether the roots can grow or not is not only determined by the hardness of the soil. There are three factors that inhibit the growth of crop roots. (1) mechanical resistance derived from soil hardness, (2) soil aeration, which indicates whether sufficient air is being pumped into the soil so that root respiration is not adversely affected, and (3) soil moisture conditions. These factors are not independent of each other, but are interrelated, making them even more complex.

7. Hardness is not an inhibiting factor in general soil

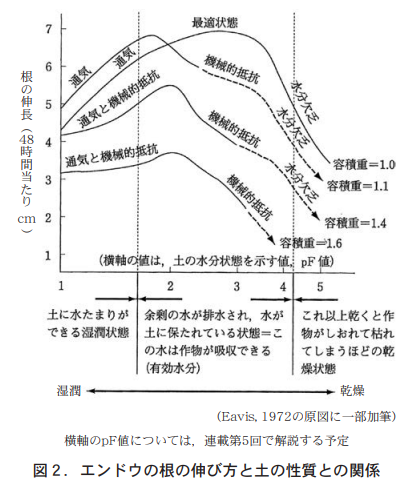

Figure 2 shows the results of an experiment examining the relationship between the above three factors and root elongation. The volumetric weight of 1.0 in Figure 2 indicates that 1 cm3 contains 1 g of dry soil, which is a very normal value for ordinary soil. The increase in volumetric weight can be thought of as the soil particles becoming finer and more cohesive.

そこで図2によると,土に水たまりができるような湿潤状態では,土の中のすき間は水で満たされており,土に酸素が不足する(通気不良)。このため土の容積重に関係なく,エンドウは酸素不足で根を十分に伸ばせない。

When there is no puddle and the soil contains some water, mechanical resistance, i.e., soil stiffness, will now inhibit root growth. However, this is the case for slightly fine-grained (clayey) soil with a volume weight of more than 1.1. Ordinary soil with a volume weight of up to 1.0 has water and air in the spaces between the soil, so it is in optimum condition for root growth.

When the soil becomes dry, mechanical resistance due to hardness inhibits root elongation in soils with large volumetric weights (fine-grained and clayey). However, in a typical soil with a volume weight of 1.0, mechanical resistance due to hardness does not inhibit root elongation. And, of course, in a soil so dry that the crop wilts, lack of water inhibits root elongation regardless of the volume weight.

In other words, it is concluded that soil hardness is a problem in fine-grained soil (clayey soil), and that in general soil hardness itself should not be considered to be an impediment to root growth. For soils with low volumetric weight and light weight, such as black granite soil (soil derived from volcanic ash), soil hardness is hardly a problem. In fact, because of its lightness, black soil is susceptible to wind erosion (soil being blown away by the wind).