Site Search

Search within product

第728号 2021 (R03) .02-03発行

Click here for PDF version

農業と科学 2021/02-03

本号の内容

§トマト,メロンの紐栽培における肥料袋の

投入箇所と培地の太陽熱消毒について

Former Graduate School of Natural Science and Technology, Okayama University

桝田 正治

今野 裕光

§<産地レポート >

JA Tamba Hikami, Hyogo Prefecture, active in "yam" cultivation

緩効性肥料「CDU化成S555」について

Jcam Agri Corporation West Japan Branch

Fertilizer bags in tomato and melon cord cultivation

投入箇所と培地の太陽熱消毒について

Former Graduate School of Natural Science and Technology, Okayama University

桝田 正治

今野 裕光

Introduction.

For more than 10 years since the author first introduced the root-supporting watering string method1, 2) , we have solved the capillary material encapsulation problem, planted tomatoes and melons in a three-in-one ring of soil, water, and fertilizer, and conducted research on the growth of these plants. In the case of tomatoes, fertilizer was applied in permeable bags, and the bags were removed at the end of cultivation to reuse the sandy soil. The bags were placed on strings inside the container, but when the bags were placed on the strings, the fertilizer easily dissolved in capillary water, causing the seedlings to temporarily suffer from high salt stress immediately after planting, resulting in wilting.3) To avoid this salt stress, it is important to avoid the initial salt stress. To avoid this salt stress, it is first necessary to design fertilizers that inhibit initial leaching, and then, if the fertilizer bag is placed far from the planting position, salt stress immediately after planting should be reduced. In this case, there will be a large difference in nutrient concentration in the medium, but will the roots respond to this difference in concentration and grow well?

The method of planting an individual plant at the boundary (center) of two compartments and allowing its roots to grow in different environments and measuring the growth response of the above-ground portion is generally referred to as the "split-roots method "4, 5) . Sonneveld and Voogt (1990) described this method as a "split-roots system" in rockwool cultivation of tomatoes, in which a tomato plant was planted at the boundary of two plots set at different EC values and its growth was observed. As a result, he found no difference in growth and yield between the two plots, even if one had a higher or lower EC than the other, as long as the other had an appropriate EC6) .

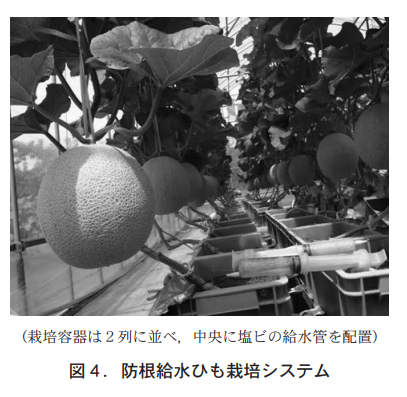

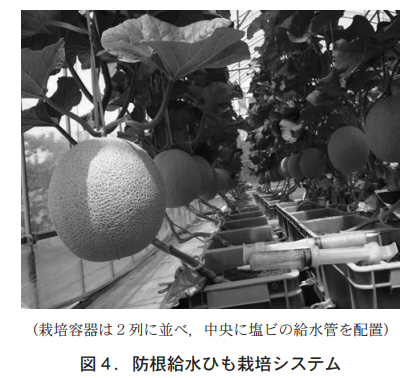

This result suggests that even if the bagged fertilizer is placed where it is not in direct contact with the string, the roots will grow in response to the solution concentration and the above-ground parts will grow normally. Therefore, we investigated the growth, yield, and leaching of fertilizer nutrients by placing bagged fertilizers "on the string," "next to the string," and "under the seedlings" at planting time. In addition, we investigated whether placing the bags on the opposite side of the aisle from the string insertion slot is reasonable in terms of cultivation management (Figure 4, see photo), and whether this would cause problems with fruit growth and quality.

Even if the fertilizer bags can be removed at the end of harvest, the treatment alone does not ensure stable fruit production in successive cropping. In particular, disinfection of the culture medium is necessary for continuous cropping of melons, and solar disinfection has been used for the past four years to avoid soil diseases.

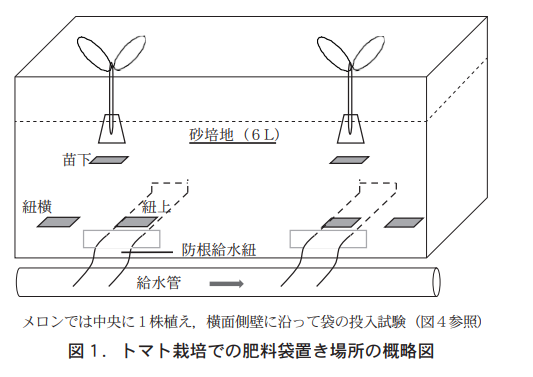

I. Overview of Tomato Cultivation Trials

The tomato variety tested was the medium-sized 'Red Ole'. The seedlings were sown on August 20 in 200-hole cell trays filled with commercial sowing medium, and on September 8 (when the second leaf developed), 3 g of Ecolong Total 313, 70 type was mixed into a PVC pot containing 200 ml of river sand medium from which more than 2 mm particles were removed, and the seedlings were transplanted and bottom watered. The container (19 cm (length) X 33.5 cm (width) X 15.5 cm (height)) was partitioned horizontally in half, and one plant was planted in 3 L of sandy medium per plot and watered with water from a string. Fertilizer was placed in a commercially available 10.5 x 11.0 cm tea bag, and three plots (10 plants in each plot) were placed "on the string," "beside the string," and "under the seedlings. Fertilizer was applied approximately 2 cm above the bottom of the container in the "above the string" and "beside the string" areas, and approximately 5 cm above the string in the "below the seedlings" area (Figure 1).

Five porous cups connected to a soil solution collector were placed directly above the fertilizer bags in each plot at planting. The fifth cluster was harvested on January 15, and the cultivation was terminated.

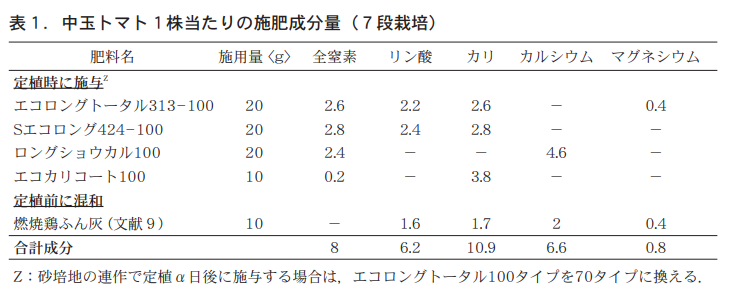

(1) Fertilization design

The fertilizer design per plant is shown in Table 1. In order to minimize early growth wilting, the ECOLONG TOTAL 40 type was replaced by the 100 type. The fertilizer leaching rate at the end of harvest was about 80% of that in the 7-high cluster cultivation, because 5-high bunches were harvested this time, while 7-high bunches were harvested in the previous crop (3) (data omitted).

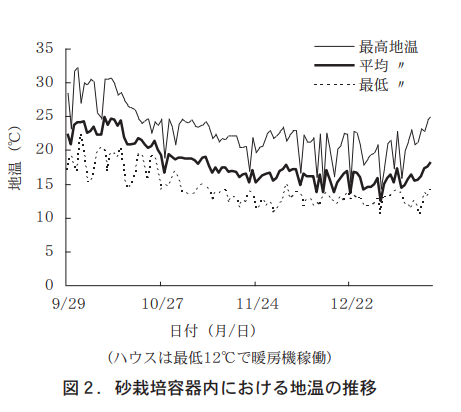

(2) Variation in soil temperature of sand media

Figure 2 shows the soil temperature change from the beginning of October to the end of December, with the minimum temperature in the greenhouse being 12°C from November onward, and the soil temperature also changed accordingly. The difference between the maximum and minimum daily soil temperatures is large in this cultivation method (10-15°C on sunny days) because of the isolation of the growing medium and its small quantity.

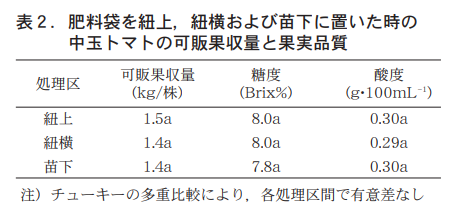

(3) Fruit survey

The yield and quality of harvested fruit are shown in Table 2. Fruit sugar content was about 8, and acidity was 0.3 g/100 mL-1 citric acid equivalent of juice, which did not differ among treatments.

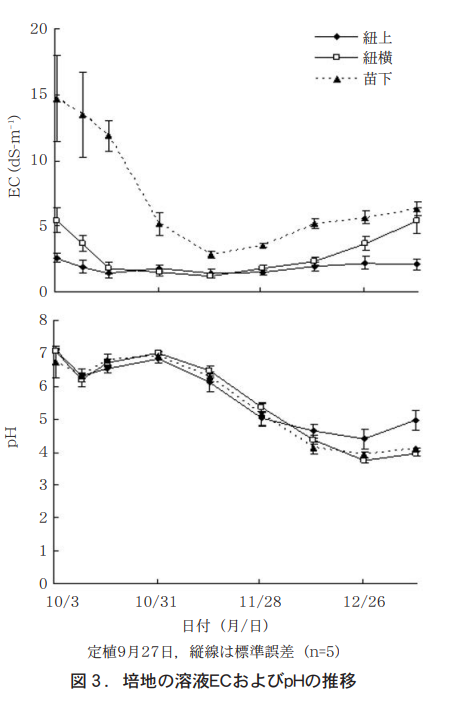

(4) Medium and fertilizer nutrient survey

The EC and pH of the medium solution are shown in Figure 3. On October 3, the first week after planting, the EC was 2.6 dS-m-1 in the upper rows, 5.4 dS-m-1 in the lateral rows, and 14.7 dS-m-1 in the lower rows, with the lower rows showing particularly high values. The EC values in the upper rows did not fluctuate significantly and remained in the range of 1.4 to 2.2 dS-m-1 until the end of cultivation. On the other hand, the EC value in the lower part of the seedling gradually decreased until November 14, the 7th week after planting, but remained at a minimum of 5.0 dS-m-1, and the EC value was always higher than that in the upper and lateral sections (Figure 4).

(5) Consideration - Root capacity

Water in the medium rises from the bottom of the medium, so the moisture content is higher in the lower part of the medium and lower in the upper part. The reason why the EC of the solution in the medium was higher in the "under seedlings" section than in the "above string" and "beside string" sections is that the water content in the "under seedlings" section was higher than that in the "above string" and "beside string" sections because the bag was located at a higher position.

The lower EC concentration in the "under the seedlings" area may be due to the higher fertilizer concentration in that area. The fact that there were fewer roots around the bag at the "bottom of the seedling" than at the "top of the string" and "side of the string" may be due to the high EC solution in that area, which caused the roots to selectively avoid that area. However, the position of the bag did not affect the yield of saleable fruit or the sugar and acid levels of the fruit. This suggests that the roots probably change their distribution in response to differences in soil solution concentration and, to this extent, do not affect fruit yield or sugar content.

Sonneveld and Voogt (1990), mentioned above, divided the roots into two compartments in the root division method, one of which was set at 2.5 dS-m-1 and one of which was supplied with 0.75, 2.5, and 5.0 dS-m-1 culture solution, and found no significant difference in both fruit sugar and acidity between the two compartments when compared to 2.5 dS-m-16). m-1, there was no significant difference in sugar content and acidity of fruit at 0.75 and 5.0 dS-m-1 compared to 2.5 dS-m-16). This report suggests that even if the EC is high in some parts of the medium, there is no difference in fruit quality and no problem if there is an appropriate concentration in some parts of the medium. Tabatabaie et al. (2004) divided the roots into two compartments in a root division method, one control compartment where both were supplied with the same concentration of culture medium with an EC of 3.0 dS-m-1 and one treatment compartment where one compartment was supplied with tap water and the other with relatively high EC of 4.5 and 6.0 dS-m-1. The K content in the fruit was higher in the treatment with 4.5/0 and 6.0/0 dS-m-1 than in the treatment with 3.0/3.07).

Although the bag treatment of this method should also have resulted in a non-uniform solution concentration and partially high EC values, no differences in yield, fruit acidity, or incidence of greenback fruit occurred, probably because the monovalent ion K is absorbed selectively and efficiently.

The above results indicate that the fertilizer bag does not need to be placed "on the string," and that there is no difference in yield or quality whether the bag is placed "next to the string" or "under the seedlings," suggesting that it does not matter where the bag is placed within a limited growing container. The results also strongly suggest that the planting hole treatment of fertilizer with regulated fertilizer, which has been reported for many crops, can be applied to tomatoes as well.

II. Overview of Melon Cultivation Trials

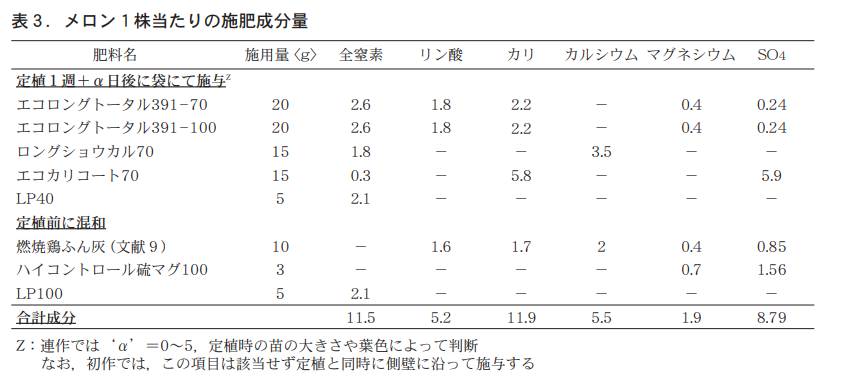

Melons can be grown in unheated greenhouses from mid-May to late October when the minimum temperature does not fall below 12°C in Okayama Prefecture. The variety is a spring variety of 'Earl's' and 'Phébolite', which has been maintained as a pure line by occasional self-propagation, and was originally released as a spring variety at the Shizuoka Prefectural Agricultural Experiment Station. The cultivation method is based on a paper published in 20108) on melon cultivation in mid-summer, but the fertilizer design has been modified little by little based on growth and fruit merchantability, and the current design is shown in Table 3.

(1) Fertilizer design and application methods

Particularly noteworthy here is the use of a larger amount of Ecocaricoat, and the mixing of Mag 100 sulfur in all layers prior to planting. The former was to avoid leaf margin necrosis of node-appearing leaves, and the latter to avoid intervein chlorosis. In addition, fertilizer is applied in bags one week plus α days after planting, which speeds up the leaching of the coated fertilizer to 70 types. In melon cultivation, fertilizer was initially put in tea bags and placed on the strings as in the case of tomatoes, but this forced the bags to be placed when the strings were set, making it difficult to completely avoid the risk of high salt injury that occurs immediately after planting, as mentioned above. When the fertilizer bag was placed along the side wall of the string insertion opening, there was no difference in growth compared to the "on the string" method, and the fruits enlarged without any problem.

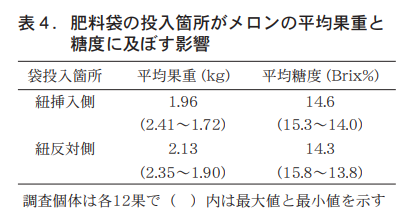

(2) Bag feeding point and fruit enlargement

The fact that the bags can be inserted along the side wall of the string insertion slot means that they can be processed at any time after planting and can be removed even during the cultivation process. However, as can be seen from the photograph in Fig. 4, the cultivation containers are set in two rows with a PVC pipe in the center, so if the bags are put in on the side of the string insertion opening, it is difficult to perform the work described above. We investigated whether there would be a difference in fruit growth if the fertilizer bags were applied on the opposite side of the string insertion opening (aisle side): seedlings were sown in early June 2016 and planted when the third leaf developed, and one week later fertilizer bags were applied along the side wall. The average fruit weight was over 1.9 kg and the average sugar content exceeded 14.5 (Table 4).

However, the opposite side of the string tended to have a slightly larger variation in sugar content. As a result of the above, it was concluded that the string introduction area

The team concluded that it is reasonable to feed the bags along the side of the container on the opposite side of the aisle from the

(3) Solar disinfection of culture media to enable continuous cropping

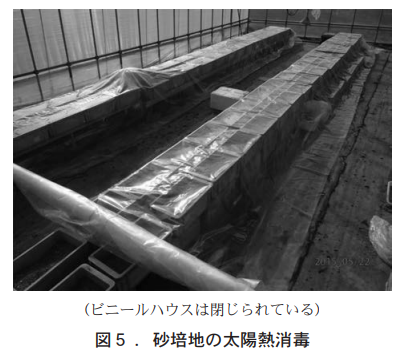

In the third year of a row in 2014, many of the plants showed a waterlogged appearance at the base of the stem and did not reach harvest time even after application of the chemical topzine paste. Since many brown and irregularly shaped black spots were observed on the roots of these plants, we concluded that they had homopsid root rot, which is commonly known as homopsid root rot. Solar disinfection of the medium was then attempted (Fig. 5).

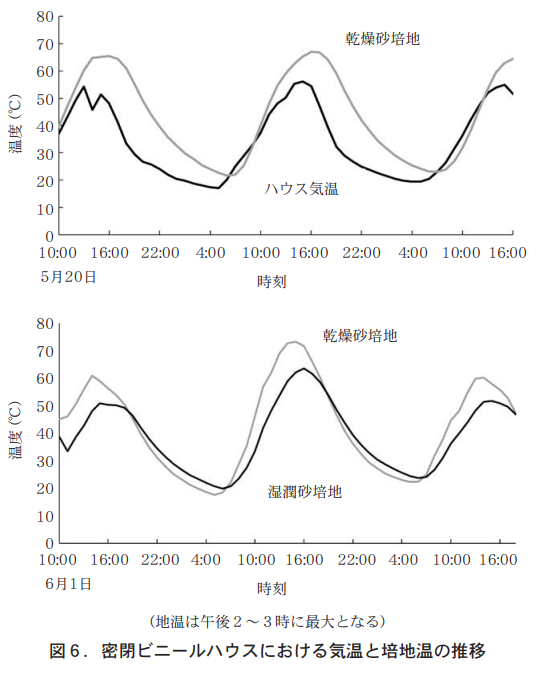

Based on weather reports of clear skies, the greenhouse was closed for three days, and a polyethylene sheet was placed over a container of dry sandy medium. The temperature in the greenhouse was 55°C, and the medium temperature was 10°C higher than that, reaching more than 65°C. The temperature of the wet medium was 10°C lower than that of the dry medium (Fig. 6). The temperature of the wet medium was about 10°C lower than that of the dry medium (Fig. 6, bottom).

It has since been verified that in the agricultural climate of Akaiwa City, Okayama Prefecture, the medium temperature can rise to 65-70°C on sunny days after April 20. Thus, soil diseases are almost completely controlled by solar disinfection, and the cultivation of 'Allsphevorit' is now possible.

III. General Considerations

The following question (answer) was given in the Biology Question 3B of the National Center Test for University Entrance Examinations (NCTE) in 2008. In the soil environment where nitrate ions are unevenly distributed, Arabidopsis senses a lack of nitrogen source and transmits the information from the roots to protein X, which is produced in the above-ground part of the plant. Protein X then promotes the uptake of nitrate ions by increasing the expression of gene Y in . In other words, this problem requires us to derive the answer in [ ] from the results of the presence/absence experiment of nitrate in the underground part and the grafting experiment in the above-ground part by the root division method. If we further universalize this, we can assume that the absorption of components other than nitrate ion is promoted by a similar mechanism, and that the roots absorb nutrients while maintaining a dynamic equilibrium between cations and anions to ensure the survival of the plant as an individual.

The root division method described at the beginning of this paper and the questions posed in this Arabidopsis experiment suggest that the nutrient-sensing capacity of plant roots is extremely high and that fertilizer does not need to be mixed in homogeneously. It is evident that the information of excess or deficiency of nutrients is transmitted to each root via the above-ground portion to ensure the survival of the plant as an individual. Although some nutrients leached from the bag remained in the medium, the EC value did not exceed 0.4 at a sand:water ratio of 1:2. This is close to the value obtained when growing vegetable seedlings, and will not be a problem in the next crop. After harvest, the fertilizer bag taken out of the medium is placed in a bucket, and the fertilizer that is dissolved in water can be used as a culture solution for other vegetable seedlings.

Fertilizer design for any crop is a continuous process of trial and error, and it is not the end of the process. It is not the end of the process. Modifications are made based on the development of fertilizers and varieties, the planting season and growing season, and changes in the agricultural climate. Among the fertilizers discussed here, it is necessary to pay particular attention to the amount of Ecocaricoat applied. In tomatoes, yellowing of leaf margins and greenback of fruits3) and browning of leaf margins near the fruiting node in melons10) are caused by potassium deficiency.

In order to prevent this, it is necessary to consider the leaching type of potassium coat and the amount of potassium applied. The sulfate ions that are the counter ions of potash are listed in Table 3.

Sulfur is a shadowy and abundant element for plants.

Generally, sulfur is not a problem because ammonium sulfate and potassium sulfate are applied. However, when continuous cropping is attempted on a small amount of medium, it is important to supplement sulfur consciously. In hydroponic tests on tomatoes, SO4-S levels of 2 to 22.5 me-L-1 were considered to be in the appropriate range11) , and the sulfate ion provided in hydroponic garden culture medium is magnesium sulfate (MgSO4) with a molecular weight of 120, and this Mg:SO4≈1:4, 2 me-L-1. 1:4 and 2 me-L-1. In Table 3, Mg:SO4 ≈ 1:4.6, which is close to the ratio in the standard culture medium. The amount of Ecokalicoat and Magnesium Sulfate applied in Table 3 was set considering the SO4 deficiency of chicken manure ash and Ecolong Total alone.

On the other hand, the technology related to solar disinfection of the culture medium was already established in the late Showa period, and an overview of that period is discussed in the section "Soil Degradation and Physiological Disorders" 12). More than 801 TP3T of continuous cropping disorders in vegetables are caused by soil diseases, and the actual physical disinfection methods for their prevention have recently been summarized by Kita 13). Diseases such as wilt and blue wilt of tomatoes, and vine blight and homopsis root rot of melons are completely killed in 1 to 2 hours at 55°C or higher. In particular, the melon homopsis fungus in question here is generally killed in one hour at 46°C. The sand medium used in this method is completely isolated and the soil temperature reaches 65°C (Figure 6).

In addition, oidium as an above-ground disease and oidium whitefly and spider fly as insects are problematic, but the greenhouse temperature can reach 55°C or higher when the greenhouse is sealed, and these diseases and insects can be strongly controlled as long as no external invasion is allowed after disinfection. Thus, solar disinfection of greenhouses is an indispensable technology for the stable production of tomatoes and melons in this method.

Reference materials

1.「毛管給水ひも」によるトマト栽培の可能性について.

桝田正治・福本祥子.岡山大農学報 97:49−54.2008.

2.「防根給水ひも」によるトマトの新規栽培手法.

桝田正治.農業及び園芸83:20−25.2008.

3.防根給水ひもによるトマト砂栽培への紐上置き肥の適用.

今野裕光・桝田正治・村上賢治.園芸学研究11:227−234.2012.

4.大麦による硫酸態イオウの吸収および同化,

根分け法による要素欠乏および各種塩類の影響の検討.

鳥居賢治・藤原彰夫.土壌肥料学会誌38:16−20.1967.

5.Analysis of soybean rhizobial formation process at different times of the year and in vitro by nitrate nitrogen applied by the root division method.

谷田沢道彦・吉田重方.土壌肥料学会誌38:379−382.1967.

6.Response of tomatoes (Lycopersicon esculentum) to an unequal distribution of

nutrients in the root environment. Sonneveld, C.and W.

Voogt. Plant and Soil 124:251−256. 1990.

Uneven distribution of nutrients in the root zone affects the incidence of blossom

end rot and concentration of calcium and potassium in fruits of tomato. Tabatabaie,

S. J., Gregory P. J. and P. Hadley. Plant and Soil. 258:169−178. 2004.

8.盛夏期における防根給水ひもを用いたメロン砂栽培の可能性.

川原雅規・桝田正治.岡山大農学報101:13−18.2012.

9.鶏ふん燃焼灰のバイオ強酸水処理に伴う肥料成分の溶出量の変化.

畑直樹・村上賢治・桝田正治・秋庭英治・太田靖子.農業及び園芸82:1295−1301.2007.

10.アールスメロンの紐栽培—肥効調節型肥料の全量基肥と吸肥・吸水パターン—.

桝田正治・山岡史和.農業と科学717:9−14.2020.

Effect of sulfur deficiency and excess on yield and sulfur accumulation in tomato

plants. Cerdá, A., Mertinetz, V., Caro, M. and F. G. Fernández. J.

Plant Nutrition 7:1529−1543. 1984.

12; Degradation and Physiological Disturbances of Soils. Masuda, Shoji. New Horticultural Science 292-298, 1998. pp. 292-298.

13. Effectiveness and Diffusion of Physical Disinfection Methods. Kitayoshi Y. Journal of Vegetable and Tea Research 3: 7-15. 2006.

<Production Area Report

JA Tamba Hikami, Hyogo Prefecture, active in "yam" cultivation

緩効性肥料「CDU化成S555」について

Jcam Agri Corporation West Japan Branch

The "yam" is a brand-name agricultural product of Hyogo Prefecture, grown mainly in the Tanba region of Hyogo Prefecture since ancient times.

It is said that cultivation began in this area in the early Edo period. Because Tamba City is a basin surrounded by mountains, there is a large temperature difference between day and night from fall to winter, and deep morning fog occurs. The "yama-no-imo" grown here is also called "kiri-imo" (sweet potato grown in the mist).

The "yam" does not grow wild like the yam, but is a cultivated crop. Soil conditions are important for the growth of yam, and the soil in the Tamba region is considered suitable for this purpose. The "yam" of the Tamba region is sticky, and when grated, its stickiness is much stronger than that of other types of potatoes.

Slow-release fertilizer "CDU Kasei S555" is used for "yam" cultivation by JA Tamba Hikami.

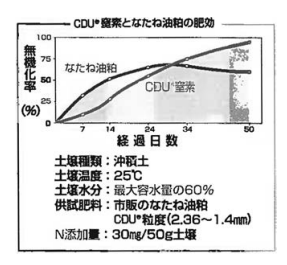

CDU Chisso is mineralized by microorganisms in the soil and then absorbed by the crop. The feature of CDU chisso is that it is more efficiently absorbed by crops than organic fertilizers such as rapeseed oil cake, because the mineralization rate of chisso is higher.

It is highly evaluated that the fertilizing effect of the fertilizer lasts from the vine growth period to the leaf growth period of the "mountain potato" and that it grows leaves with good color.

We are receiving.