Site Search

Search within product

第726号 2020(R02).12発行

Click here for PDF version

§Municipal waste molten slag as fertilizer and application development

Shizuoka University, Faculty of Agriculture

Department of Applied Life Sciences

准教授 一家 崇志

§鉢もの花き栽培における緩効性肥料による省力施肥

Jcam Agri Corporation Kyushu Branch

郡司掛 則昭

§2020 General Table of Contents of Previous Issues of this Journal

Fertilization of Municipal Solid Waste Molten Slag and Application Development

Shizuoka University, Faculty of Agriculture

Department of Applied Life Sciences

准教授 一家 崇志

Introduction

In 2006, JIS standard for molten slag was established, and quality control of molten slag is now in progress. In recent years, the majority of molten slag has been utilized as construction and civil engineering materials, mainly as aggregate for secondary concrete products, aggregate for asphalt mixtures, and aggregate for backfilling. On the other hand, molten slag is expected to be applied to other industries where high value-added and stable market scale can be expected, especially in the agricultural field. This is because the main component of molten slag is silicic acid, and its composition ratio is the same as that of "Silical" (lime silicate fertilizer) produced from blast furnace water-breaking slag, which is familiar as an agricultural material.

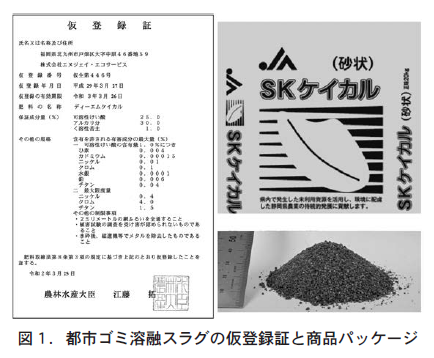

Since 2013, our research group has been working with Shizuoka City and Nippon Steel & Sumikin Engineering Corporation (now Nippon Steel Engineering Co., Ltd.) to convert molten slag into fertilizer through a series of demonstration tests. As a result, on March 27, 2017, molten slag produced at the Nishigaya Cleaning Plant in Shizuoka City, Shizuoka Prefecture, was approved by the Ministry of Agriculture, Forestry and Fisheries as a fertilizer for the first time in Japan, and is now commercially available as SK Keikal by JA Shizuoka Keizairen (Figure 1). The characteristics and adaptability of molten slag as an agricultural material were evaluated through demonstration tests on rice plants that use silicic acid as a useful element.

2. effect of silicon on plants

Silicon (Si) is an essential element for animals, but it is not recognized as an essential element for plants and is not necessarily required by all plants. However, silicon is considered a useful element for plants because the application of siliceous fertilizers improves or has a positive effect on the growth of many plants, especially grasses.

The beneficial effects of silicon on plants are diverse. For example, the accumulation of large amounts of silicon in rice leaf blades improves mechanical strength and enhances photosynthesis by improving the photosensitive state of the leaves. In addition, the accumulation of silicon in the stem increases stem strength, which in turn improves resistance to overturning. This directly leads to a reduction in damage caused by typhoons during the harvest season.

In addition, accumulation of silicon in the plant body is effective in improving resistance to various stresses. For example, in addition to reducing abiotic stresses such as rice blast, powdery mildew, and insect damage such as leafhoppers and fungus, silicon also contributes to the reduction of non-biotic stresses such as nutrient deficiencies, low temperature, high temperature, and drought stresses. These facts indicate that silicon has an effect on plants to reduce combined stresses, and as a result, contributes greatly to yield increase of crops.

3. demonstration test in rice paddies

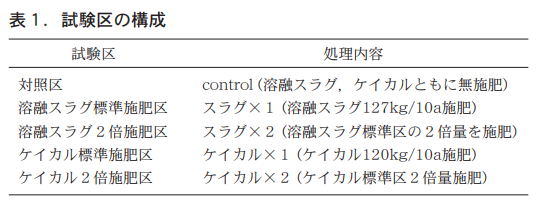

We conducted paddy rice cultivation tests using molten slag from the Nishigaya Cleaning Plant in Shizuoka City, Shizuoka Prefecture [treatment method: shaft furnace type (coke bed type) gasification and melting method] in accordance with the test areas shown in Table 1.

なお,水田による水稲栽培試験は栽培履歴の異なる2ヶ所の水田で行なった:2013と2014年は静岡大学農学部内の水田(静岡県静岡市駿河区大谷) ,2017年は静岡大学附属フィールド内の水田(静岡県藤枝市仮宿) 。512穴セルトレイで1か月程度育苗したイネ「コシヒカリ」を,1株1本植えにて水田に移植した(株間30cm,条間15cm) 。

基肥および穂肥は静岡県の施肥基準(平坦地,コシヒカリ)に従い,窒素(N,塩化アンモニウム) ,リン酸(P,過リン酸石灰;P2O5) ,カリウム(K,塩化カリウム;K2O)をそれぞれ2kg,3kg,3kg/10aとし,1回目の穂肥はN,P,Kをそれぞれ2kg,0kg,2kg/10a,2回目の穂肥はN,P,Kをそれぞれ1kg,0kg,1kg/10aとなるように施肥した。

Cultivation trials at Shizuoka University were conducted under constantly waterlogged conditions, while cultivation at the Fujieda field was conducted under medium-dry conditions for about two weeks. Throughout the growing period, each agronomic trait (culm length, ear length, number of ears, etc.) was surveyed (10 individuals were randomly selected from each block), and a yield survey was conducted by tsubo-harvesting. The traits were randomly divided into five blocks within each treatment, and the yield per 10a was calculated from the average of the yield per tsubo mowing. The silicic acid (Si) content in the hemp leaves and rice husks was calculated by the gravimetric method using wet ashing followed by drying. The amount of molten slag (soluble silica: 32%) applied was calculated from the standard amount of Silical (soluble silica: 34%) applied of 120 kg per 10 a. (All of these values were measured and analyzed before the test).

Table 2 summarizes the results of the last three years' trials. Although there was not much difference in culm length and ear length due to slag or silica fertilizer application compared to the control, a significant increase in ear number was observed, especially in the 2013 trial. In addition, there was a significant increase in each yield trait with siliceous fertilizer application compared to the control. In particular, straw weight (biomass weight), hull weight, and weight of polished brown rice increased with the amount of siliceous fertilizer applied, with the highest increase observed in the area fertilized with twice the amount of slag. The highest increase was observed in the area with 2x slag fertilization. The increase effect was further enhanced by the continuous application of fertilizer in the second year.

The paddy field in the Faculty of Agriculture, Shizuoka University, which was used for this study, had been completely neglected for many years and had not maintained its function as a paddy field until immediately before the test. Therefore, we stripped all of the surface soil of about 10 cm, along with weeds, just prior to the cultivation test, and began the test cultivation by plowing the field anew. This meant that there was no silicon supply to the paddy field and that a large amount of silicon was taken out from the paddy field. Therefore, the effect of siliceous fertilizer application was probably very pronounced in the first-year trial. On the other hand, the 2017 results from the Shizuoka University farm were conducted in paddy fields where rice was continuously cultivated, so the effect of silica fertilizer seems to be somewhat lower than in the Shizuoka University Faculty of Agriculture, but the yield increase of about 101 TP3T was still observed in the slag-added area.

Overall, the above results indicate that the application of siliceous fertilizers has a positive effect on rice growth, and the effect is equal to or greater than that of conventional silical fertilizers. Although not mentioned in this report, the content of toxic metals such as cadmium, lead, and mercury in brown rice due to slag application were all below the standard values, indicating that there were no adverse effects of slag and its safety was confirmed.

4. Conclusion

In modern human activities, we are constantly troubled by the problem of waste generation. Waste disposal is also one of the issues in disaster recovery. The shaft furnace type gasification and melting furnace, which melts rather than burns garbage, can safely process garbage of all kinds of materials and contributes greatly to the reduction of garbage volume. The conversion of molten slag derived from municipal solid waste into fertilizer, which we have demonstrated, can be called the ultimate in recycling. In September 2015, the United Nations General Assembly adopted the Sustainable Development Goals (SDGs) consisting of 17 goals and 169 targets as an action plan for people, the earth, and prosperity, and efforts to achieve the SDGs are being promoted by industry, academia, and government alike. The Sustainable Development Goals (SDGs) are a set of 17 goals and 169 targets.

When considering the SDGs from the perspective of food, it is clear that many things are indeed relevant. The recent global environmental changes and the COVID-19 pandemic have had a tremendous impact on the economic and industrial worlds. However, while there is an urgent need to build a system for increasing crop yields that can withstand explosive population growth and dramatic global environmental changes, achieving this goal will be extremely difficult. In other words, the key is to break through the current status quo of agricultural production and build a sustainable agricultural system that can efficiently utilize the earth's finite resources. To achieve this, we need to establish efficient cultivation methods that require less water, and at the same time, provide tolerance to biotic and abiotic stresses so that healthy growth can be maintained even under adverse environmental conditions. Silicon is also a key nutrient for solving the above problems.

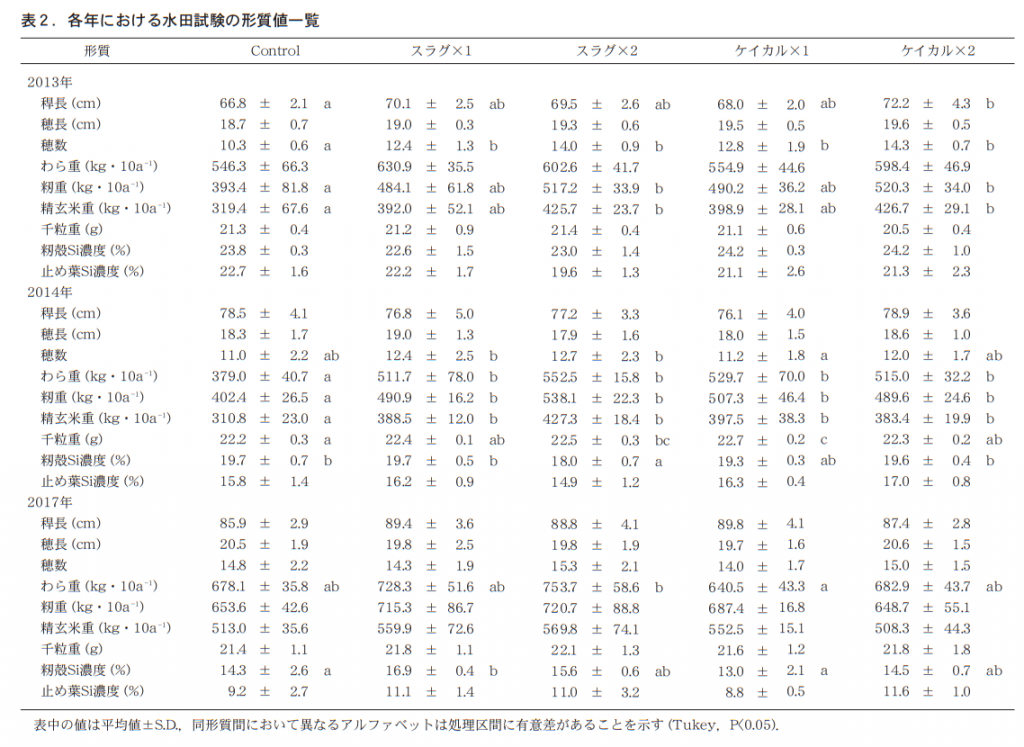

We have demonstrated the effectiveness of molten slag as a siliceous fertilizer through cultivation trials since 2013. In order to further demonstrate the effectiveness of molten slag, we are currently testing its effect on the growth of various plants in addition to other grass species (e.g., water bamboo and sugarcane), with positive results obtained in all cases (Figure 2). In addition to fertilizers and biological residues, rainwater and irrigation water also supply nutrients to the paddy fields. Silicic acid, which has a negative nutrient balance in paddy fields, is an important element in rice cultivation and needs to be supplied continuously to maintain the health of rice plants.

On the other hand, it has been reported that the silicate content in soil and the supply of silicate from water have been decreasing in Japan in recent years. This is related to various factors, but the main factor is considered to be the yearly decrease in the amount of siliceous fertilizers applied. Silicon is the only nutrient that does not cause plant damage due to excessive application, as is often observed with other nutrients. As mentioned above, the promotion of the use of siliceous fertilizers, including molten slag, will be key to maintaining stable quality and production in response to the poor growth of crops caused by abnormal weather conditions that are occurring on a global scale.

Labor-saving fertilization with slow-release fertilizers in potted flower cultivation

Jcam Agri Corporation Kyushu Branch

郡司掛 則昭

Introduction

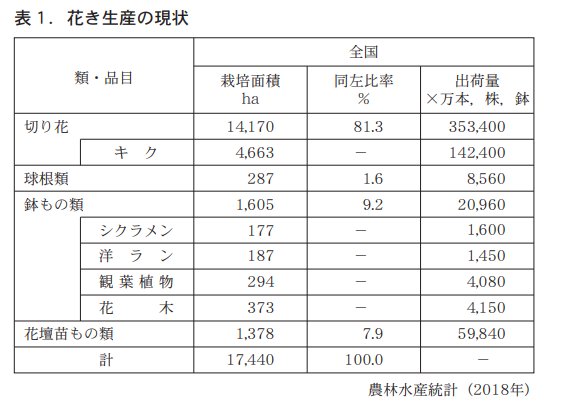

Flowering plants are plants that enjoy their flowers and leaves, and are classified into cut flowers, bulbs, potted flowers (hereinafter referred to as "potted flowers"), and flower bedding plants. Among these, cut flowers such as kiku (Asteraceae) are widely produced, accounting for 81.31 TP3T of the total cultivated area of 17,440 ha in Japan. Potted flowers, on the other hand, are very popular as a luxury item to enjoy beautiful flowers and leaves indoors, but the cultivated area in FY 2008 was only 1,605 ha, less than 101 TP3T of the total (Table 1).

Potted flower sales were probably flourishing around the height of the bubble economy, but since then, sales of potted flowers have been declining except for orchids such as the orchid. This is due to the decline in consumption due to the economic slowdown, as potted flowers themselves are a luxury item, but it is also thought to be due to the special characteristics of potted flower cultivation, such as the large number of products and varieties, the delay in basic research, and the fact that potted flowers are grown in pots rather than in the soil. In order to ensure healthy growth, it is a priority to provide a proper growing environment in pots, and in particular, sufficient attention must be paid to the physical strength of the pot to support the plant body, the nature of the culture medium that provides moisture and oxygen essential for growth, and fertilizer application that provides almost all the nutrients. The following are some of the most important factors to be considered

Here, I would like to discuss the characteristics of the culture medium required for potted flower cultivation and labor-saving fertilization techniques using slow-release fertilizers.

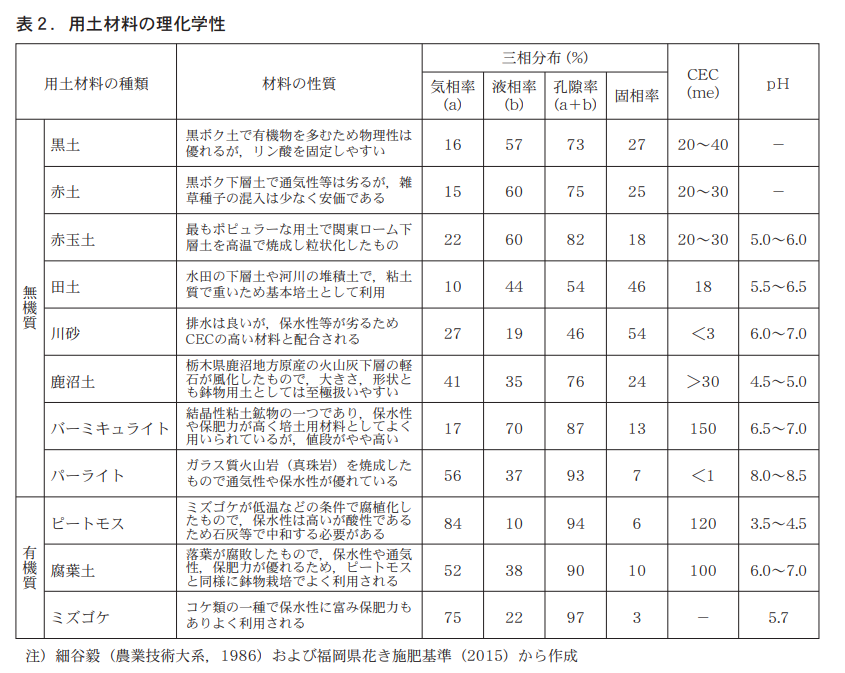

2. conditions as culture medium for potted flowers

Potted flower cultivation is one of the root-zone-restricted cultivation methods in which flowering plants are grown in a limited space inside a pot. In limited root zone cultivation, the amount of soil per potted flower is smaller than in soil cultivation, so the quality and growth of flowers are strongly influenced by the physical and chemical properties of the culture medium in the pot. There are approximately three conditions that must be met by the culture medium. The soil should have the following three conditions: a moderate degree of solids content to provide physical strength, a high porosity to provide sufficient water and air retention, and a high CEC to retain nutrients. In addition, the material must be lightweight, inexpensive, and readily available.

Usually, inorganic soil materials such as akadama soil and kanuma-soil are mixed with organic materials such as peat moss and humus. The former inorganic materials provide adequate solids content and porosity, while the latter organic materials provide light weight, high porosity, and CEC. Table 2 shows the physical and chemical properties of commonly used soil materials.

Here, attention should be paid to the pH of peat moss. Peat moss is a very commonly used soil material because of its light weight and excellent physical properties. However, the pH of peat moss is as low as 3.5 to 4.5, which may cause the pH of the culture medium to drop depending on the mixing ratio. The pH should be checked when using peat moss.

Effective fertilizer application for potted flower cultivation

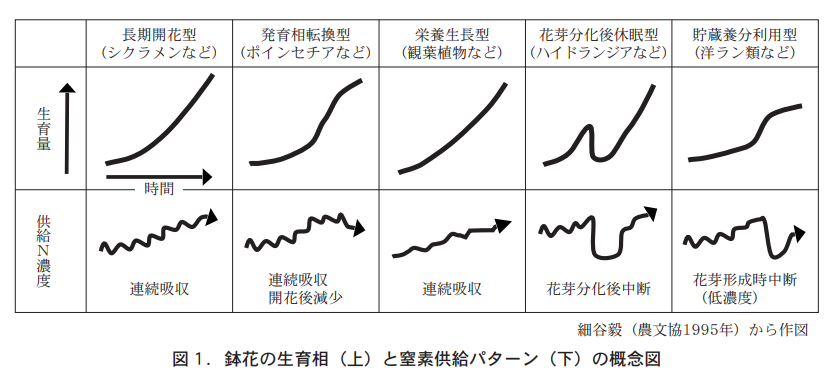

Even if appropriate soil materials are combined, the culture medium itself does not contain any nutrients, so the nutrients necessary for growth must be supplied by fertilization. The key point is to consider the different growth phases of each potted flower and apply nitrogen fertilizer accordingly.

鉢花の生育相については細谷1)によって既に取りまとめられている(図1) 。これによれば,シクラメンなどの長期開花型,ポンセチアなどの発育相転換型,観葉植物などの栄養生長型,アジサイなどの花芽分化後休眠型,洋ラン類などの蓄積養分利用型に分けられる。このうち長期開花型,発育相転換型や栄養生長型の生育相を示す鉢花においては,種類や生育期間の長短によって施肥量の違いこそあれ生育全般を通して切れ目のない持続的な窒素供給が必要である。これに対して,花芽分化後休眠型や貯蔵養分利用型では,生育初期には窒素要求性は高いが,花芽分化期や開花期以降にはあまり必要としないような窒素供給を考えなければならない。

Thus, in the cultivation of potted flowers, any fertilizer can be selected as long as the nitrogen supply can be matched to the growth phase, but liquid fertilizers are currently the mainstream. This is because the required amount of fertilizer can be applied to the pot at the required time, whether as a primary or a secondary fertilizer, at the same time as irrigation, allowing precise application while checking the growth phase.

However, for potted flowers such as cyclamen, which require continuous absorption of nutrients during the growing season, the use of liquid fertilizers for all fertilizer application is recognized as a management problem, as it increases the frequency of fertilizer application and leads to higher costs. For this reason, the use of slow-release fertilizers is being promoted to save labor.

Types and characteristics of slow-release fertilizers

The slow-release fertilizers mainly used for labor-saving purposes in potted flower cultivation are our brand names: Long, a coated compound fertilizer, and IB Nitrogen, a slow-release nitrogenous fertilizer.

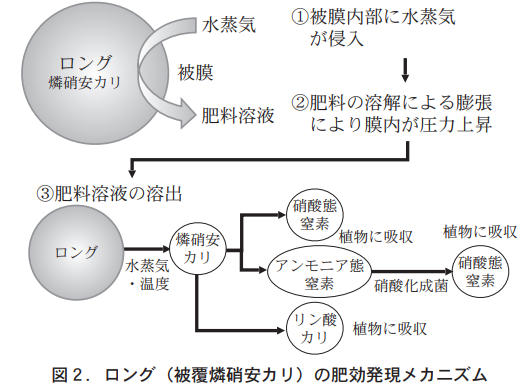

Long is a coated fertilizer made by coating potassium phosphonitrite with polyolefin resin as a seed component, and is available in a variety of grades, including compound fertilizers with different ratios of nitrogen, phosphoric acid, and potassium, and those containing trace elements. When long is applied to the soil, water vapor penetrates into the coating, and phosphorus nitrate and potassium gradually leach out as an aqueous solution to produce the fertilizing effect (Figure 2).

For this reason, it is important to mix it with soil to obtain a long and stable nitrogen fertilizing effect, and it is used exclusively as a primary fertilizer at the time of potting up or repotting. Nitrogen-leaching types are roughly classified into linear and sigmoidal types, and various brands are available with nitrogen-leaching periods ranging from 40 to 360 days. Currently, the long type has been converted to the Ecolong series, which has a coated film with enhanced photodisintegration properties.

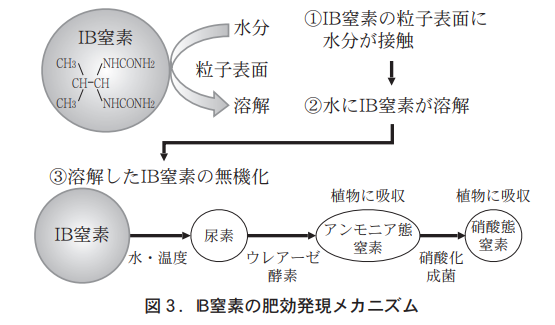

On the other hand, IB nitrogen is an organic compound consisting of urea bound to isobutyraldehyde, with a nitrogen content of 31%. The urea is gradually released through hydrolysis reaction, and the nitrogen fertilizing effect is expressed through the transformation of ammonia-form nitrogen to nitrate-form nitrogen (Figure 3). IB nitrogen is usually mixed with phosphoric acid and potassium and sold as IB Kasei (product name: IBS1), which is granulated to about 5 to 10 mm in size. IBS1 is often used as a fertilizer for flowers and vegetables, responding to growers' questions such as "How many grains should I apply per pot?

The following is a summary of the results of the survey.

Cultivation of potted flowers using slow-release fertilizers

As mentioned above, slow-release fertilizers have been introduced to save labor, and several examples using long and IB chemical fertilizers are presented below.

ロングの利用が多い鉢花はシクラメンである。たとえば,岐阜県ではひも利用樋底面給水栽培においてリニア型のロング424−140タイプ2g/5号鉢を元肥とし,150ppmNの液肥を適宜追肥するロングと液肥の組み合わせ体系2),栃木県ではマット底面給水方式のシクラメン栽培においてシグモイド型ロング424−70タイプを4月に元肥として1g/5号鉢,リニア型ロング424−70タイプを9月に4g/5号鉢を追肥し栄養診断によって必要に応じて液肥を追肥する施肥体系3),三重県ではひも利用樋底面給水栽培においてロング424−180タイプを7.5〜10g/5号鉢で全量元肥施用する施肥体系4)によって規格品生産が可能であると報告されている。このようにロングの施肥体系は様々あるが,いずれも生育相に合った養分供給が行える点では一致している。シクラメンの品種や作型,あるいは培養土の種類,経営面などを考慮して最適な施肥体系を選ぶ必要があると思われる。

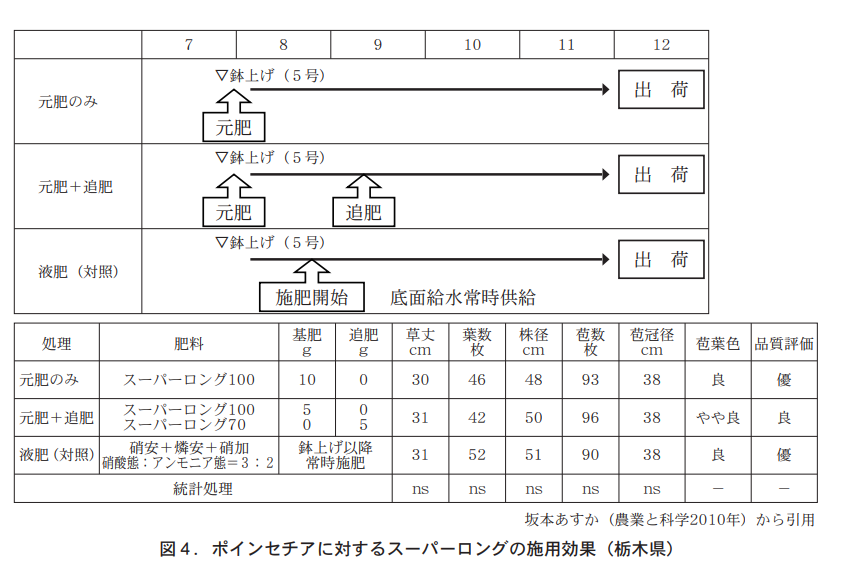

ポンセチアは比較的施肥量が多い発育相転換型の鉢花である。栃木県において行われたひも利用樋底面給水栽培では,図4に示すように,8月初めの定植時にスーパーロング424−100タイプ10g/5号鉢を全量元肥施用することにより液肥主体の慣行栽培と同等な品質となり,施肥量も慣行比で最大で約20%削減できることが認められている5)The following is a list of the most common problems with the "C" in the "C" column.

一方,IB化成であるIBS1は花だけなく野菜など鉢もの全般にわたって置肥として使われている化成肥料であるが,鉢花栽培における単独施用は少なく液肥やロングとの併用が多い。単独施用の例では,11月下旬開花の福助作りの鉢ギク栽培においてIBS1を8g/4号鉢で置肥すると,有機質肥料主体の慣行施肥と同等の品質が得られることが認められている6)The following is a list of the most common problems with the "C" in the "C" column.

Summary

Potted flowers are plants for indoor enjoyment of their flowers and foliage in pots filled with culture medium, and the nature of the culture medium and fertilization strongly affect their growth and quality.

The desirable conditions of culture soil are adequate hardness, water retention and aeration, and high fertilizer retention. Usually, peat moss and humus are selected as organic soil materials, and red ball soil and kanuma-soil are selected as inorganic soil materials, and culture soils with properties suitable for the growth of each species are prepared and used.

Liquid fertilizers are widely used because of their ease of use. However, slow-release fertilizers have been attracting attention from growers who want to reduce the number of fertilizer applications and lightening the workload for fertilizer addition, and labor-saving fertilizer application techniques have been developed, such as total fertilizer application using a coated composite fertilizer long and placement of large-grain IBS1.

In order to promote the use of slow-release fertilizers in potted flower cultivation, it is necessary to understand the in-pot environment, which is affected by the nature of the culture medium, to clarify the effect of slow-release fertilizers on nitrogen fertilization, and to expand the fertilization standards that are currently set only for a limited number of crops to other crops.

References

(1) T. Hosoya, Nutritional physiology and fertilization of flowering plants, Noubunkyo, 1995.

2)住井正康,シクラメンの底面給水栽培におけるロング肥料の活用,

農業と科学12月号,1989.

3)高橋 正,肥効調節型肥料を利用したシクラメンの施肥管理技術,

栃木県農業試験場研究成果集24,2005.

4) Etsuzo Nishida, Nao Nakano and Masayuki Kamada, Studies on fertilizer application in bottom-feeding cyclamen cultivation.

三重県農業技術センター研究報告22,1994.

5)坂本あすか,ポインセチアの養分吸収量と肥効調節型肥料を用いた省力施肥管理技術,

農業と科学3, 4月号,2010.

(6) T. Hosoya, Hachigiku, Compendium of Agricultural Technology, Soil Fertilization Edition, Noubunkyo, 1998.

General Index of Previous Editions of this Journal in 2020

<January issue

Toward the §2022 era

ジェイカムアグリ株式会社

管理本部長 安藤 嘉章

§鹿児島県島しょ地域におけるサトウキビ栽培土壌の理化学性の実態

鹿児島県農業開発総合センター

餅田 利之

§アールスメロンの紐栽培肥効調節型肥料の全量基肥と吸肥・吸水パターン

元 岡山大学農学部

桝田 正治

山岡 史和

<February/March combined issue

§日本土壌インベントリー(e−土壌図Ⅱ)が目指す土壌情報の発信

農研機構農業環境変動研究センター

環境情報基盤研究領域 土壌資源評価ユニット

高田 裕介

§沖縄県の主要3土壌における肥効調節型肥料を利用したオクラ春植え栽培の省力施肥について

沖縄県農林水産部 農業研究センター 名護支所

主任研究員 田中 洋貴

<April issue

§硬質小麦の高品質安定生産を実現する省力施肥技術の開発

三重県農業研究所 農産研究課

研究員 内山 裕介

(現 四日市農林事務所 四日市鈴鹿地域農業改良普及センター 鈴鹿普及課 主任)

§Seedling boxes and pooled seedlings go hand in hand.

ジェイカムアグリ株式会社 東北支店

技術顧問 上野 正夫

<May issue

§山形・宮城の伝統野菜(里芋各種)産地における土壌調査

宮城大学 食産業学群

齊藤 秀幸

§ Fertilizers and nutrients:

被覆燐硝安加里(ロング・ハイコントロール・Nutricote)の特性について(その1)

柴田技術士事務所

柴田 勝

<June issue

§ Fertilizers and nutrients:

被覆燐硝安加里(ロング・ハイコントロール・Nutricote)の特性について(その2)

柴田技術士事務所

柴田 勝

§ Soil and fertilizer management to improve soil fertility in tea plantation soils

ジェイカムアグリ株式会社 九州支店

郡司掛 則昭

<July issue

§ Fertilizers and nutrients:

被覆燐硝安加里(ロング・ハイコントロール・Nutricote)の特性について(その3)

柴田技術士事務所

柴田 勝

§ Utilization of Soil Data in Aichi Prefecture

愛知県農業総合試験場 瀧 勝俊

.

§密苗Ⓡにおける播種時緩効性肥料「マイクロロングトータル280−100」の施用効果

渡島農業改良普及センター

主査 辻 敏昭

§ Points to keep in mind for soil fertilizer management in Global GAP

宮城大学 食産業学群

齊藤 秀幸

<Oct.

§ICT技術を利用した次世代型の主食用米の多収技術構築

株式会社ファーム・フロンティア

山形大学農学部 客員教授

藤井 弘志

§露地野菜の畝連続栽培におけるセル苗全量基肥を用いた省力技術の試み

鹿児島県農業開発総合センター

生産環境部 土壌環境研究室

加治屋 五月

<Nov.

§ Establishment of a one-shot application method for passion fruit basal fertilizer

岐阜県農業技術センター

鈴木 哲也

§Labor saving in promotion cultivation of eggplant by total basal application of fertilizer

福岡県農林業総合試験場

森田 茂樹

<Dec.

§Municipal waste molten slag as fertilizer and application development

静岡大学学術院農学領域

応用生命科学科

准教授 一家 崇志

§ In the cultivation of potted flowering plants

緩効性肥料による省力施肥

ジェイカムアグリ株式会社 九州支店

郡司掛 則昭

§2020 General Table of Contents of Previous Issues of this Journal