Site Search

Search within product

第731号 2021 (R03) .06発行

Click here for PDF version

農業と科学 令和3年6月

本号の内容

§加里不足圃場への加里肥料増施

による大麦収量性の改善

Toyama Prefectural Technology Center for Agriculture, Forestry and Fisheries

Agricultural Research Institute

南山 恵

§土のはなし−第2回

よい土の条件 物理的性質−その1

根を支える土の厚み

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Increased application of potassium fertilizer to potassium-deficient fields

による大麦収量性の改善

Toyama Prefectural Technology Center for Agriculture, Forestry and Fisheries

Agricultural Research Institute

南山 恵

Introduction.

Toyama Prefecture produces Fibersnow, a six-row barley that is highly regarded by consumers for its suitability for processing. In particular, for high quality and stable production of barley, one of the most important technical measures is the practice of soil preparation and accurate application of basal fertilizer. In soil preparation, the company encourages the active application of compost and other organic matter, calcareous materials, and soil improvement materials. As for the precise application of base fertilizer, side-row fertilization with a controlled-release fertilizer that combines fast-acting base fertilizer and coated urea is widely practiced, and "LP Barley No. 48" is mainly used.

On the other hand, in recent years, in Toyama Prefecture, there have been many fields where basic and important nutrients such as soil pH and exchangeable potassium have fallen below standard values, and the yield of "Fibersnow," barley grown after paddy rice, has been sluggish in some cases.

Based on these results, we have identified some factors that inhibit high-yield barley cultivation and have developed some measures to improve these factors.

Current Soil Chemistry of Barley Plots in Relation to the Number of Ears with Increased Application of Potassium

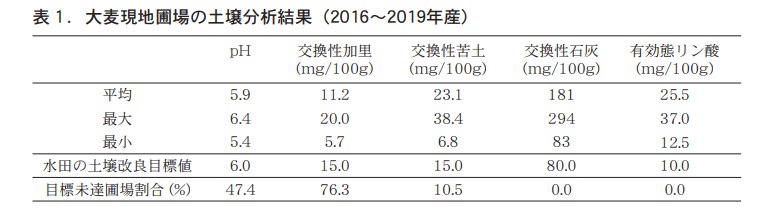

富山県内のA,B両地区の2016〜2019年産大麦圃場において,大麦播種前に作土をサンプリングしてpHや交換性塩基含量などの土壌化学性を分析したところ,土壌の交換性加里が水田の土壌改良目標値15mg/100gを下回る割合が76.3%と高く,圃場の平均値は11.2mg/100gと低くなった(表1)。

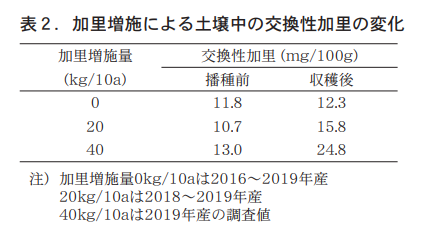

After that, 20 to 40 kg of potassium/10a was added to the barley field to see the change of exchangeable potassium in the soil.

ろ,大麦播種前に比べ収穫後の交換性加里含量が増加することがわかった(表2)。

Increased application of exchangeable potash for stable and high yield

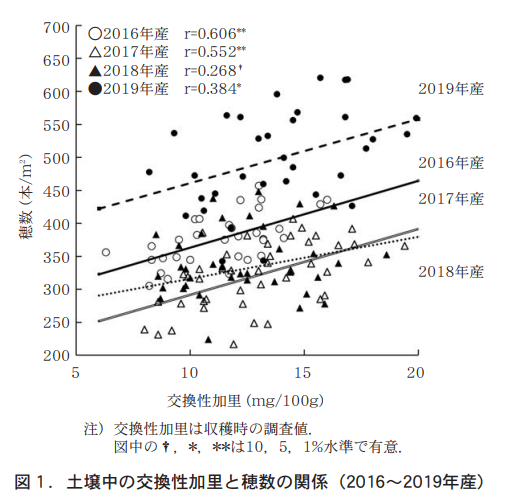

Furthermore, in plots with exchangeable potassium in the soil after harvest of less than 20 mg/100 g, the number of ears of barley harvested in each year of the four-year period tended to decrease with decreasing exchangeable potassium (Figure 1).

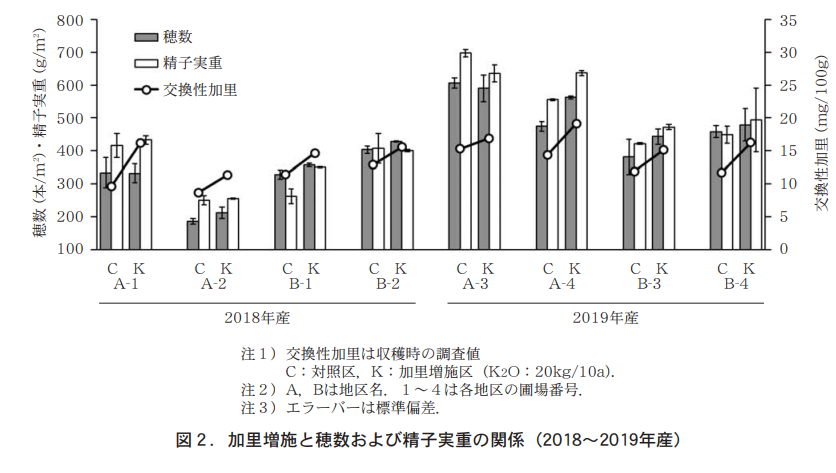

Therefore, considering the possibility that the lack of exchangeable potassium in the soil may have affected the yield, we conducted a countermeasure test by increasing the amount of potassium component by 20 kg/10a. As a result, the number of ears increased and sperm seed weight increased in most of the test plots (Figure 2).

In District A, where this test was conducted, about 80 kg/10 a of slaked lime was applied, and in District B, about 100 kg/10 a of bitter lime and 100 kg/10 a of fermented silica fertilizer were applied as soil improvement materials before plowing. In addition, LP barley No. 48 (nitrogen-phosphate-calcium: 30-9-9), a fertilizer with controlled fertilizer effect, was applied at the time of seeding at 40-48 kg/10a in lateral strips.

summary

These results indicate that in barley fields with exchangeable potassium in the soil below 20 mg/100 g, the number of ears and sperm seed weight increased when 20 to 40 kg/10a of potassium was added to the soil. The potassium chloride fertilizer used in this study was granular potassium chloride, which was applied before tillage. 20 kg/10 a of potassium chloride was equivalent to 34 kg/10 a of potassium chloride.

Conclusion

In this issue, I have introduced the relationship between barley, one of the key crops in Toyama Prefecture, and exchangeable potassium in the soil.

It has been nearly 10 years since the deficiency of potassium was pointed out in Toyama Prefecture, especially in medium-coarse-grained paddy soils, which are typical paddy soils in Toyama Prefecture. Potassium is one of the three major elements of fertilizers and is an essential nutrient for crops. It is hoped that crops will absorb potassium not only from fertilizers but also from the soil, leading to stable production of agricultural products, as well as safe and secure agricultural products.

The contents presented in this paper were conducted as part of a project research entitled "Development of Diagnostic Methods and Countermeasures for Factors that Inhibit High Yield" commissioned by the Ministry of Agriculture, Forestry and Fisheries of Japan.

No Soil - Part 2

よい土の条件 物理的性質−その1

根を支える土の厚み

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

In last month's issue, we presented four conditions and their target values for good soil for crop production. From this month onward, each of the four conditions will be explained. In this issue, we will focus on the first condition, "soil thickness and hardness," which is one of the conditions related to the physical properties of soil, and consider its thickness.

First, let's dig up the soil.

In last month's issue, I mentioned that a veteran chef at a famous hotel in Sapporo remarked that he could harvest many delicious potatoes just by looking at the soil. However, I do not have the courage to say such a thing. I don't know what is inside the soil where the roots of the crops grow, even if I stand in the field where the crops are cultivated (the same is true in a home garden) and look at the soil from above. You cannot know what is inside the soil unless you dig it up. First of all, I would like you to choose an area where the crop growth is average in the field and dig the soil by yourself with a shovel.

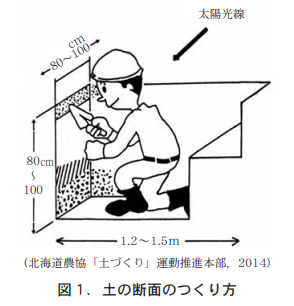

掘る深さは1mが目安。太陽を背中に受けるようにして掘る(図1)。ただなんとなく掘るのではなく,自分に対して正面となったところは,土の表面から垂直に壁状にすることに気をつける。この壁状となったところを土の「断面」という。

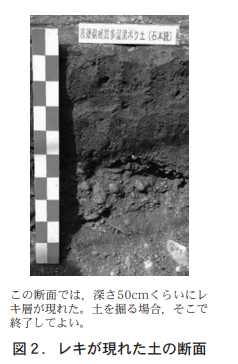

土をスコップで掘っている時,スコップから伝わってくる土の硬さや感触を記憶しておいてほしい。土を楽に掘れるかどうかは,次回に予定している「土の硬さ」の条件と関わりがあるからだ。掘っている途中で土が硬くて掘れなくなるとか,石ころ(礫=レキ)がゴロゴロ出てきて掘れないということになったら,そこで作業を終了する(図2)。

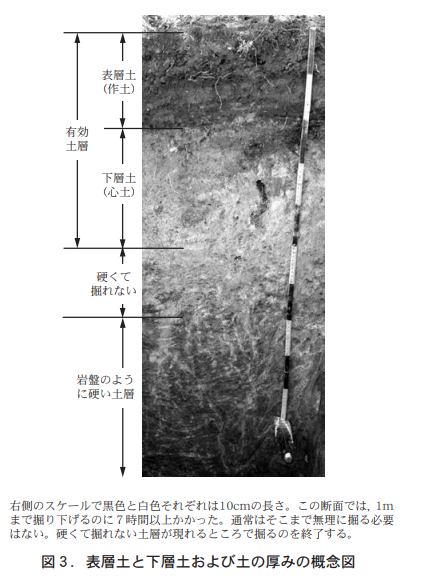

2. soil has two different thicknesses

土の断面を眺めると,断面の上部に黒色を帯びた土の層と,その下に黒色が消えた層があることに気づくだろう(図3)。この黒色を呈した層の土を表層土(または作土)という。その下の黒色が消えた層の土が下層土(または心土)である。下層土は表層土との境界からスコップで掘れなくなったところまでと便宜的に考えることにする。

作物生産にとってよい土であるための条件の一つとした土の厚みには,2つの種類がある。一つは表層土の厚みである。もう一つは,根が土の中で楽に伸びることができる厚みである。この厚みの範囲を有効土層という(図3)。

To be a good soil for crop production, the thickness of the surface soil should be about 20 to 30 cm, and the effective soil layer should be at least 50 cm thick. For example, in the cross section of soil shown in Figure 3, the thickness of the surface soil is about 20 cm. The thickness of the subsoil from the boundary to the point where it is too hard to dig is about 30 cm, so when combined with the thickness of the surface soil, the effective soil layer is about 50 cm. Therefore, it can be judged that the soil in Figure 3 just barely meets the two thickness requirements for good soil.

3. surface soil thickness is closely related to tillage operations

The surface soil is the uppermost part of the soil cross-section and is black in color. In arable land, various organic materials are added to the soil surface, including harvest residues after cultivation, roots of crops left in the soil, and compost. These materials are then plowed into the soil by plow tillage and mixed with the soil by rotary tillage. Organic matter mixed with the soil is gradually decomposed by microorganisms in the soil. The part of the organic matter that is not easily decomposed by microorganisms remains in the soil and becomes soil organic matter (humus). Humus is a black complex organic compound that gives the surface soil its black color.

As the added organic matter is repeatedly incorporated and mixed deeper into the soil, the thickness of the surface soil gradually increases. Thus, the surface soil is affected by human influence. Therefore, if the thickness of the surface soil does not reach 20 cm, which is the lower limit of the target value, it can be increased by actively feeding organic matter such as compost.

This topsoil is sometimes referred to as crop soil in agricultural terms. However, the thickness of the two is not always the same. The crop layer is the layer of soil within the area where the soil is plowed inverted by the plow. The depth at which the soil is plowed is the thickness of the crop layer.

The surface soil provides a place for crop roots to establish and absorb nutrients. In other words, this is the soil layer that has the greatest influence on crop growth. Human activities on the soil for crop production are also basically directed to the surface soil. The management of the surface soil is an important factor in determining the crop productivity of a field.

4. soil thickness that allows roots to grow

It is virtually impossible to increase the thickness of the soil that allows roots to grow, i.e., the effective soil layer, through farming operations. As already mentioned, it is possible to artificially improve the thickness of the surface soil. However, the thickness of the subsoil beneath the surface layer cannot be altered by human manipulation unless it is done by civil engineering. The major factors that determine the effective soil layer are a layer of pebbles that roots cannot pass through, bedrock, and dense hard soil. These layers will not move unless they are removed by civil engineering. Therefore, we cannot improve them by farm work.

Figure 2 shows an example where a large amount of leki is present at about 50 cm from the soil surface, which limits the thickness of the effective soil layer. It is possible to use a machine to determine whether or not there is any rubble in the subsoil layer. However, such exploration is not common. Also, the presence of the hard, difficult-to-excavate soil layer shown in Figure 3 in the soil can basically only be determined by digging.

The effective soil layer is the soil layer within which the crop roots can spread. If the effective soil layer is too thin, not only will it not be able to adequately support the crop, but it will also limit the area where nutrient water can be absorbed. If the effective soil layer is restricted to a thickness of less than 50 cm, crop growth is inhibited. However, it is quite difficult to artificially increase its thickness.