Site Search

Search within product

第733号 2021 (R03) .08発行

Click here for PDF version

農業と科学 令和3年8月

本号の内容

§水稲多収品種「ミズホチカラ」に対する

育苗箱全量施肥による省力栽培と大規模経営体における導入効果

Kumamoto Prefectural Agricultural Research Center, Production and Environment Research Institute

研究参事 柴山 豊

(現在 熊本県県北広域本部阿蘇地域振興局)

§土のはなし−第4回

よい土の条件物理的性質−その3

断面でわかる排水の良否

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

水稲多収品種「ミズホチカラ」に対する

育苗箱全量施肥による省力栽培と大規模経営体における導入効果

Kumamoto Prefectural Agricultural Research Center, Production and Environment Research Institute

研究参事 柴山 豊

(現在 熊本県県北広域本部阿蘇地域振興局)

Introduction

In Kumamoto Prefecture, reorganization of production organizations has been promoted in many areas as a measure to address the shortage of rice paddy crop bearers, and the development of large-scale management organizations and corporations that can sustain their operations is progressing. A major management challenge for these large-scale operators is how to secure stable income while reducing costs and labor.

In addition to staple rice production, there are many cases of farmers trying to stabilize their business by introducing new rice varieties (rice for animal feed, rice for rice flour, rice for processing, and rice for animal feed) that can take advantage of subsidies from the national and local governments (subsidies for utilizing rice paddies, production area subsidies, etc.). High-yielding rice varieties are used for this new rice demand, and "Mizuhochikara" is one of the main varieties.

As for low-cost and labor-saving, the "Seedling Box MAKASEⓇ" system for paddy rice has been widely used in a certain area of the prefecture, and some large-scale operators have adopted this technology to reduce costs and save labor during busy periods such as wheat harvest and preparation of paddy rice crop.

One of the points to be considered when using this method of full seedling box fertilization in normal season cultivation of paddy rice in warm southwestern regions is that seedlings tend to grow taller during seedling growth. Although there are not many examples of high-yielding paddy rice varieties grown with full seedling box fertilization, Mizuhochikara is said to have a relatively low tendency to grow taller at seedling stage than other paddy rice varieties in the prefecture, and it is even difficult to obtain sufficient seedling length with conventional seedling cultivation methods. For this reason, it is expected to be compatible with full fertilizer application in the seedling box.

Therefore, we investigated seedling quality, growth, and yield of the paddy rice variety Mizuhochikara when grown using the whole seedling box fertilization method, and examined the management benefits of introducing this variety into a large-scale management entity. Both trials were conducted over a three-year period from 2016 to 2018.

2. seedling quality and suitability for machine transplanting of "Mizuho Chikara" using whole seedling box fertilization

(1) Seedling quality test details

Sowing trials were conducted in mid-late May, which is the standard time for normal season cultivation in Kumamoto Prefecture, under the assumption that the seedlings would be transplanted by machine. Two factors were used in the test: seedling location (type of nursery bed) and seedling establishment method. The seedling locations were two levels: paddy fields and fields, which are common in Kumamoto Prefecture. In the paddy field, seedlings were grown on the surface of the rice paddy that had been leveled by plowing, and in the field, seedling boxes were laid out on weed prevention sheets laid in the field. Watering was applied from the bottom of the paddy field by watering, and in the field by sprinkler tubes (Everflow).

In order to avoid the effects of insufficient watering, sufficient water was provided to the seedlings in both cases. The other factor is the method of seedling cultivation, which was divided into two levels: conventional seedling cultivation (conventional area) and full seedling box fertilization (seedling box fertilization area). In the seedling box fertilization area, 900 g of "Seedling Box MakaseⓇ N400-120" was applied per box. In addition, seedlings in the box-fertilized area were given a root-blocking treatment outside the seedlings' box. This root-blocking treatment is recommended for paddy rice seedling box fertilization in Kumamoto Prefecture, especially for paddy rice seedling cultivation.

Specifically, root barrier sheets are placed on the bottom of the box, or seedling boxes for young seedlings (with extremely small holes in the bottom of the box that do not allow roots to penetrate) are used, and root mat enrichment is promoted by root curling within the seedling box. In this study, medium-sized seedling boxes with many holes in the bottom of the box, which are commonly used in normal season cultivation, were used in the conventional treatment, while boxes for young seedlings were used in the seedling box fertilization treatment, with the intention of blocking roots. As a common feature, artificial granulated soil was used as seedling medium.

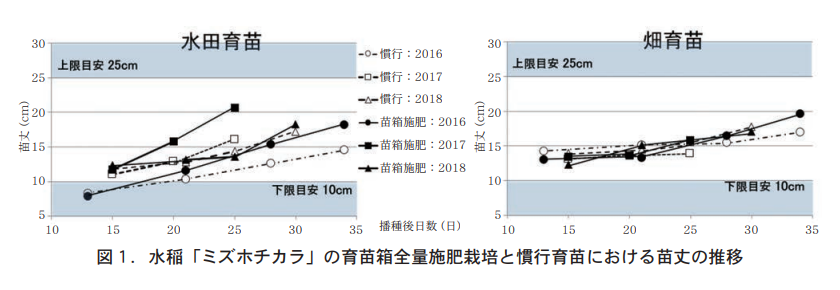

(2) Effect on seedling length

Two important items in evaluating the suitability of paddy rice seedlings for machine transplanting are seedling length and root mat strength.

The seedling height should be between 10 cm and 25 cm to allow the rice transplanter to transplant without difficulty and to keep the planted seedlings from being submerged in water. However, in areas where there is concern about feeding damage by the jumbo snail, a lower limit of at least 15 cm is desirable.

As shown in Figure 1, seedling height in rice paddy seedlings was higher in the box-fertilized area than in the conventional area in all test years. In all test areas, seedlings were able to exceed the target minimum height of 10 cm within 20 days of seedling growth, but in some years, due to the nature of Mizuho Chikara, seedlings in the conventional area did not reach 15 cm even after 25 days of seedling growth, while 15 cm was secured after 28 days of seedling growth in the full seedling box fertilization area. In the field, although there were small differences among treatments and test years, seedlings were able to reach 10 cm or more in length after 20 to 25 days of seedling growth with the full amount of fertilizer applied to the seedling box.

Based on the results of previous tests, it is known that, with other common varieties, seedlings tend to grow to 25 cm in length and become unsuitable for machine transplanting after about 25 days of full fertilizer application to seedling boxes in the paddy field during normal season cultivation, but Mizuho

No such growth was observed in Chikara in any of the test years or in any of the seedling growth methods.

Therefore, the seedlings were able to attain the necessary length for transplanting Mizuho Chikara in all seedling locations and methods, especially when the seedlings were fully fertilized in the seedling boxes, which resulted in a longer suitable transplanting period. In large paddy rice plantings, transplanting is carried out over many days, so a longer suitable transplanting period in the nursery is considered to be a major advantage.

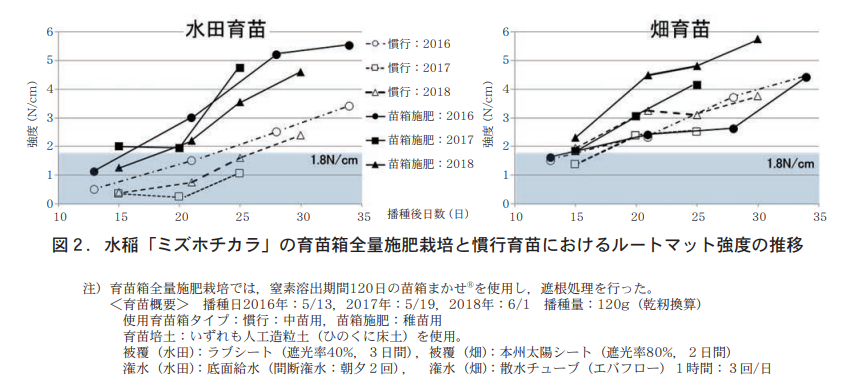

(3) Impact on root mats

ルートマットについては,熊本県では苗箱から取り出したマット苗を片手で持つために必要なルートマット強度の指標として1.8N/cm(苗マット幅1cm当たりの引っ張り切断強度が1.8N=ニュートン)を設定している。

In the rice paddy seedlings shown in Figure 2, the conventional method without root-blocking treatment failed to achieve 1.8 N/cm at 20 days of seedling growth, while the method with root-box fertilizer application did achieve 1.8 N/cm at 20 days, and the strength did not decrease even after seedling growth was continued, confirming that there is a clear difference in root mat strength depending on the seedling growth method. The rootmat strength did not decrease even after seedling growth was continued, indicating a clear difference in rootmat strength depending on the seedling growth method.

In field seedling production, although the difference by seedling establishment method was not as clear as in paddy fields, the test areas in any year were able to ensure a seedling strength of 1.8 N/cm at 20 days of seedling growth, and the strength of the seedling box fertilization area was the same or higher than that of the conventional area. It can be inferred that the presence or absence of root barrier treatment had a greater effect on root mat formation than the presence or absence of full seedling box fertilization. In addition, when we examined the interrelationship between seedling location and root barrier, we found that in rice paddies, roots extend from the bottom of the seedling box into the seedling bed soil without root barrier, but in field-grown seedlings grown on weed prevention sheets, roots do not grow much outside the seedling box, which may be the reason for the difference between rice paddies and fields.

Based on these results, it was considered that the whole seedling box fertilizer application was more advantageous than the conventional method in terms of seedling length and root mat strength for machine transplantability in rice seedling "Mizuho Chikara".

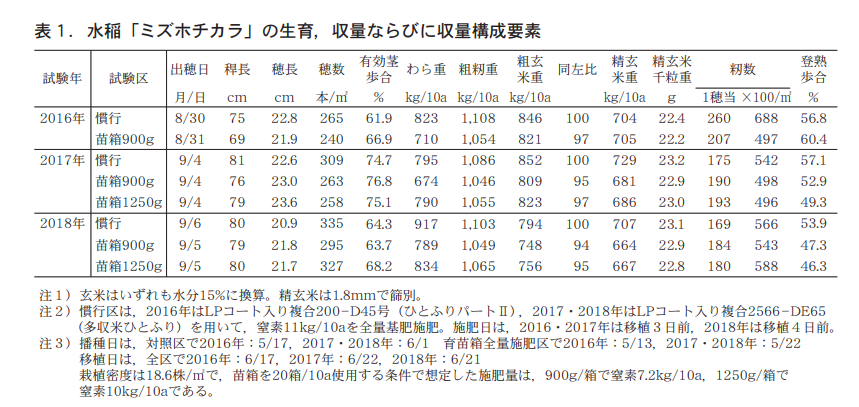

3. Yield of "Mizuho Chikara" cultivated by total fertilizer application to seedling boxes

We conducted a trial to see the adaptability of Mizuho Chikara to full seedling box fertilization in the rice paddies. The test areas consisted of three levels: a conventional area where all base fertilizer was applied with LP-coated compound fertilizer, an area where the amount of ⓇN400-120 per seedling box was 900 g, and an area where the amount of ⓇN400-120 per seedling box was 1,250 g. The amount of ⓇN400-120 per seedling box was 11 kg, which was converted to 11 kg per 10 a of nitrogen fertilizer per seedling box. In terms of the amount of nitrogen fertilizer applied per 10 a, the amount of nitrogen fertilizer applied in the conventional area was 11 kg, while in the full seedling box fertilization area, the amount was 7.2 kg in the 900 g area and 10 kg in the 1250 g area, since the number of seedling boxes used per 10 a was 20. In addition, 2 tons of cattle manure was applied per 10a in all test areas to supply phosphoric acid and potassium as well as to build up the soil. The seeding period was in mid-late May and transplanting period was in mid-late June.

As a result, the growth, yield, and yield components of each plot are shown in Table 1. 900 g plot had a crude seed weight of 94 to 971 TP3T, which was similar to or slightly lower than that of the conventional plot. The 1250g plot had a 95-97% yield ratio, and there was no effect of increasing the amount of fertilizer applied per box compared to the 900g plot.

4. total fertilizer application to seedling boxes in a large-scale operation

Evaluation of production costs for "Mizuho Chikara

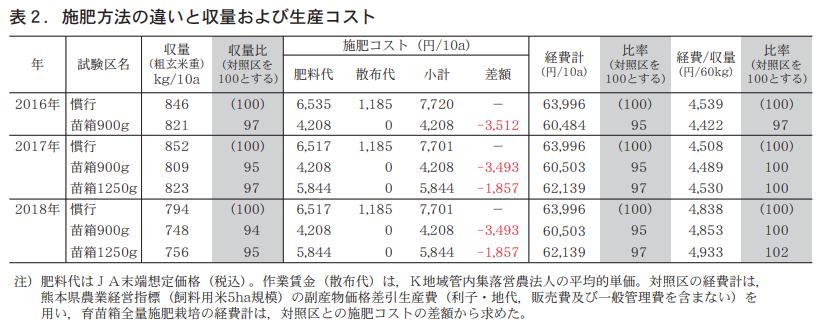

栽培試験の結果から,大規模経営体が水稲「ミズホチカラ」の育苗箱全量施肥栽培を行う際の経営メリットについて,試験年ごとに試算を行い,慣行である全量基肥施肥栽培と比較した(表2)。

First, the yield as coarse unrefined rice weight was set to 94-971 TP3T of conventional according to the results in Table 1.

Next, we compared the cost of fertilizer application for different cultivation methods. The fertilizer cost was estimated at the end-of-prefecture JA price, and the cost per 10a was lower in the 900g and 1,250g seedling box sections than in the conventional section, where the fertilizer was applied exclusively as a total base fertilizer. In addition, because of the labor cost of spreading in the conventional area, the average unit price of fertilizer in the K area of the prefecture was used to calculate the fertilizer cost. On the other hand, this cost was not incurred in the 900 g and 1250 g plots. Therefore, the fertilizer application cost in the test area was reduced by 3,512 yen in the 900 g area and 1,857 yen in the 1250 g area, compared to 7,701 yen in the conventional area.

For the total cost per 10a, fertilizer application cost and other costs indicated by the Kumamoto Prefecture management index were added. The ratio of this test section shows that the cost was reduced by 95-97% in the 900 g section and 97% in the 1250 g section compared to the conventional section.

The cost of production per product is one of the most important management indicators for large-scale management organizations aiming to improve management efficiency, and it is necessary for all management organizations to promote its reduction. Therefore, we estimated and compared the cost per product. The results showed that the total cost per 60 kg yield was approximately 4,500 yen in all the test areas, and that the cost per 900 g was 97-1001 TP3T and 100-1021 TP3T in the 1250 g area compared to the conventional area.

5.まとめ:大規模経営体の「ミズホチカラ」

栽培における水稲育苗箱全量施肥栽培の導入効果

In summary, the first advantage of adopting full seedling box fertilization for large-scale paddy rice cultivation is the assurance of adequate seedling quality. The benefits to transplanting operations are significant, as the appropriate seedling height and root mat strength ensure a longer seedling growth period. In addition, although the yield was the same or slightly lower than that of the conventional cultivation in this test, the production cost per 60 kg yield was comparable to that of the conventional cultivation. Furthermore, the use of whole seedling box fertilizer application reduces the amount of work required for spreading basal fertilizer in the paddy field. In Kumamoto Prefecture, the application of basal fertilizer to rice paddies generally coincides with the rainy season, so the fact that this work can be omitted and a series of farming operations can be planned is a major advantage.

When a large scale farmer introduces a low-cost and labor-saving technology, the merit of the technology differs depending on the characteristics of the technology, cultivar, regional characteristics, and the circumstances of the farmer.

土のはなし−第4回

よい土の条件物理的性質−その3

断面でわかる排水の良否

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

In this issue, we will first consider how to judge whether the soil drains well or not, based on the second of the four conditions for good soil for crop production, which relates to the physical properties of the soil, namely, that it retains moisture reasonably well and drains well.

1. observe the cross section of the soil closely

For example, if you have experienced a puddle of water in a field after a heavy rainfall, and the water remains there indefinitely, you should be able to feel that the soil has poor drainage properties. However, if you want to know more about how bad the drainage is, dig a hole in the soil to make a cross-section of the soil and observe it, as described in the second article of this series (June issue). You can determine whether the soil drains well or not by looking at the cross section of the soil as described below.

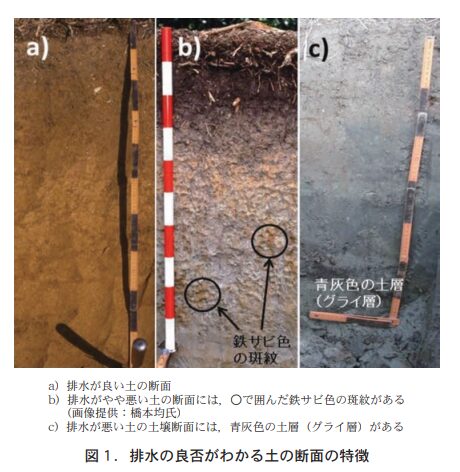

通常の土の断面には特別な模様などない(図1−a)。黒味をおびた表層土があり,その下に黒味が薄れて茶褐色の下層土が続く断面となる。このような断面を示す土は排水がよいと判断する。

ところが,断面に図1−bのような鉄サビ色(茶褐色)の模様(これを斑紋(はんもん)という)があったり,場合によっては,青みがかった灰色の土の層(これをグライ層という)を見つけたりするかもしれない(図1−c)。斑紋があるときは排水がやや悪いと判断し,グライ層は地下水が停滞するほど排水が悪いことを示している。

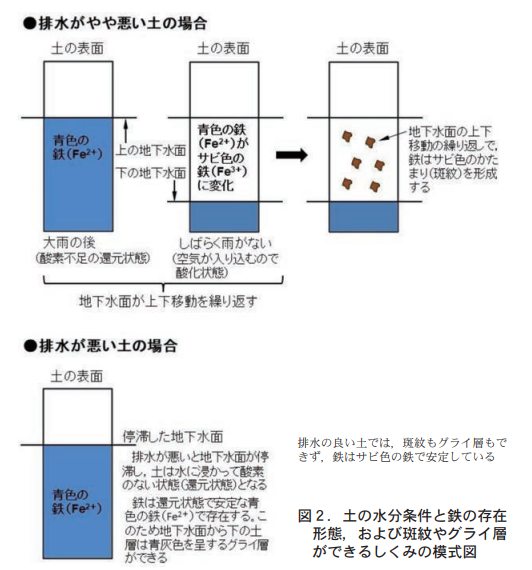

なぜ斑紋や青灰色の土から排水の良否が判定できるのか。それは土にもともと多量に含まれている鉄の性質による(図2)。

2. mottled cross section = soil with slightly poor drainage

The soil in a field has oxygen present because air can enter the gaps in the soil. This state is called an oxidative state. In an oxidative state, the iron in the soil exists as rust-colored iron that is insoluble in water. However, if the drainage of the soil is rather poor, rainwater stays in the soil during heavy rainfall, and as a result, the groundwater level rises. When this happens, the gaps in the soil are temporarily filled with water, resulting in a state of oxygen deficiency. This is called a reductive state. In the oxidative state, iron is rust-colored and insoluble in water, but in the reductive state, iron changes to blue-gray iron, which is soluble in water.

However, if the soil continues to dry out again, the water in the soil drains away little by little because the drainage is not entirely poor, the groundwater level drops, and air returns to the gaps in the soil, which becomes oxidized. The iron then turns into rust-colored iron that is insoluble in water again.

As the groundwater rises and falls with each rainfall, and the soil repeatedly goes through oxidizing and reducing states, the iron that dissolves during the reducing state collects and clumps together. This is the rusty iron mottling. Since mottling is not produced unless the groundwater level rises and falls, the presence of mottling indicates that the groundwater rises and falls because the soil drainage is somewhat poor.

3. blue-gray layer in cross section = poorly drained soil

On the other hand, if drainage is really poor, the groundwater table is relatively high because water is stagnant in the soil. Thus, the soil immersed in groundwater remains in a reduced state because the crevices are filled with water. As a result, iron continues to exist as blue-gray iron that is soluble in water, resulting in the formation of a blue-gray gley layer. Therefore, the presence of a gley layer means that groundwater is stagnant up to that point and that the soil drains very poorly.

Incidentally, when this blue-gray gley layer of soil is removed and exposed to air, it is gradually oxidized by the oxygen in the air and transformed into a rust-colored (brownish-brown) water-insoluble form of iron. Interesting properties of iron on soil color

The first is.

4. method of improving soil with poor drainage

Now that we know whether drainage is good or bad, how can we improve soil with poor drainage? In a small-scale field such as a vegetable garden, there are methods such as making ditches to allow stagnant water on the ground surface to flow out, or raising the height of the cultivation area (ridges).

しかし,農家の畑のような広い面積では,排水溝を掘る(この溝を明渠(めいきょ)という) ,あるいは,畑の地下に排水管を埋設し(これを暗渠(あんきょ)という),それを排水溝につなげるといった土木工事が必要になる(図3)。