Site Search

Search within product

第740号 2022(R04).05発行

Click here for PDF version

§茶園の施肥効率向上と省力のための条施肥技術の確立

Shizuoka Prefectural Institute of Agriculture and Forestry Technology

Tea Research Center, Department of Tea Environment Adaptation Technology

研究員 小野 嵩知

§二条大麦における肥効調節型肥料を用いた全量基肥播種溝施肥法

Oita Agriculture, Forestry and Fisheries Research and Guidance Center

Agricultural Research Department, Paddy Field Agriculture Group

清田 梨華

No § Soil - No.11

堆肥は養分移転資材として登場した

−養分の補給方法を考える−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Improving fertilizer efficiency and saving energy in tea gardens

条施肥技術の確立

Shizuoka Prefectural Institute of Agriculture and Forestry Technology

Tea Research Center, Department of Tea Environment Adaptation Technology

研究員 小野 嵩知

Introduction

In the fertilizer management of tea plantations, it is important to improve the yield and quality of tea while reducing the environmental burden.

Local fertilizer application technology has been developed as a technology that can reduce the amount and frequency of nitrogen fertilizer application due to its high utilization of fertilizer nitrogen.

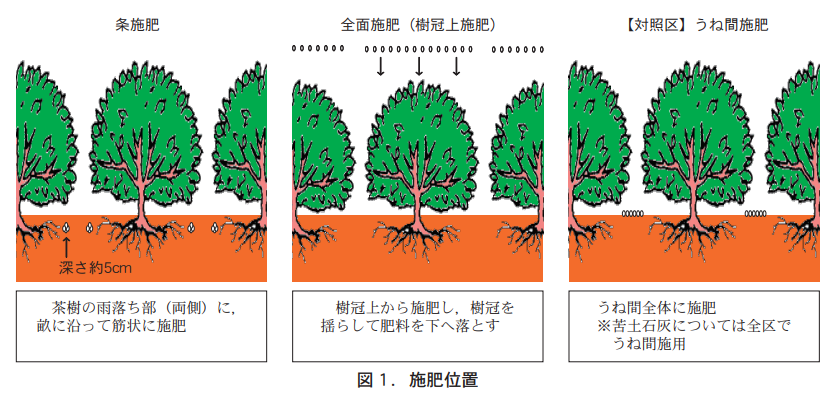

The localized fertilization technique here refers to a method of applying fertilizer in the soil below the canopy of the tea tree in the form of a tube at a depth of approximately 5 to 25 cm below the ground surface using a special fertilizer applicator. Therefore, per 10a, about 1,850 holes are dug and fertilizer is applied. The fertilizer is then applied in a cylindrical shape to each hole, which takes about 3 hours even when a special fertilizer application machine is used.

Therefore, with a view to mechanization to improve the efficiency of fertilizer application (mainly through the development of attachments for riding-type management machines), we conducted tests from FY2018 to FY2020 on the "establishment of strip fertilizer application technology to improve the efficiency of fertilizer application and save labor in tea gardens," aiming first to establish a technique to apply coated fertilizer in a streaked pattern at rain-fall areas. The results are reported here.

2. Testing Method

1) Test site: Yellow soil at the Shizuoka Prefectural Agricultural and Forestry Research Institute's Tea Research Center 2) Prototypes/variety: Chama 'Yabukita' (planted in 1988)

3)供試肥料・資材名:エコロング426−140,スーパーNKエコロング203−180,ダブルクイックNN660(ジェイカムアグリ㈱)

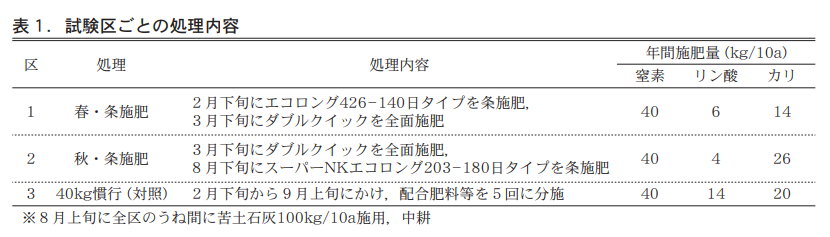

4)試験構成:本試験では,春・条施肥区に窒素溶出140日タイプのエコロング426−140,秋・条施肥区に窒素溶出180日タイプのスーパーNKエコロング203−180を条施肥した。また3月下旬には,両区ともに燐硝安加里肥料であるダブルクイックを全面施肥した(表1) 。

The position of fertilizer application is shown in Figure 1.

5)試験規模:1区9.0㎡(5.0×1.8m) ,各区3反復

(6) Survey items and methods:

a) Yield component study (20 x 20 cm frame plucking): first and second teas

(b) Fresh leaf yield: first tea, second tea, autumn/winter tea

c) Nitrogen content of plucked buds (NC analyzer): first tea, second tea, autumn/winter tea

d)土壌分析:2020年7月21日に各試験区のうね間,雨落ち部の土壌を採取(深さ0〜15cmの土壌を1区につき4箇所オーガーで採取し混合)し,pH,EC,腐植,全窒素,無機態窒素,可給態リン酸,CEC,交換性塩基について分析を行った。

3. Summary of results

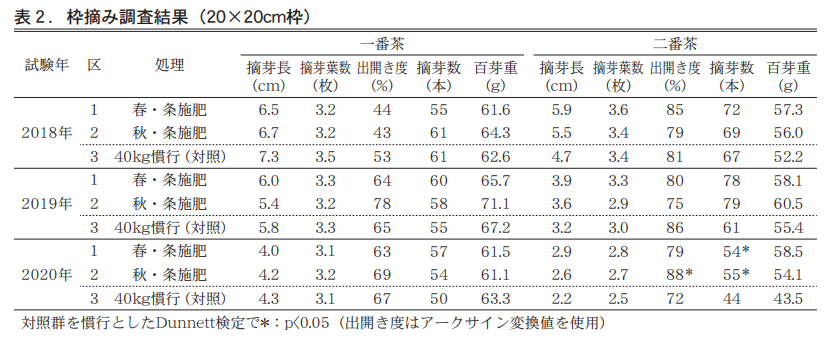

1)枠摘み調査の結果,試験3年目の二番茶において,春・条施肥区の摘芽数,秋・条施肥区の出開き度及び摘芽数は,対照区と比べて大きい数値となった(表2) 。

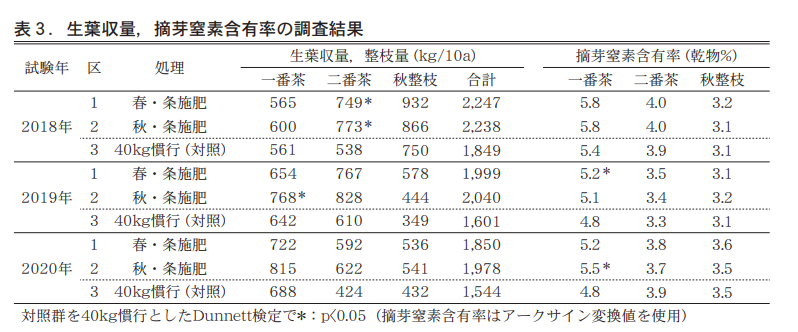

2)生葉収量は,春・条施肥区,秋・条施肥区ともに年間を通して対照区よりも多い傾向となった。特に一番茶については,試験2年目で秋・条施肥区の収量が対照区より有意に多くなり,二番茶については,試験1年目で春・条施肥区及び秋・条施肥区の収量が対照区より有意に多くなった(表3) 。

3)摘芽窒素含有率は,春・条施肥区,秋・条施肥区ともに一番茶で対照区より高い傾向となり,特に試験2年目においては春・条施肥区で,試験3年目においては秋・条施肥区で有意に高くなった(表3) 。

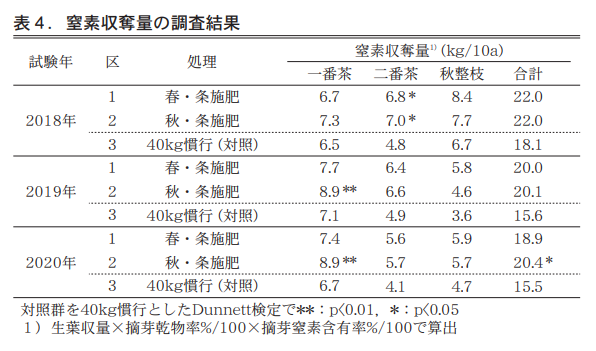

4)生葉収量と摘芽窒素含有率から算出した窒素収奪量は,一番茶においては秋・条施肥区で対照区より多い傾向となり,二番茶については春・条施肥区,秋・条施肥区ともに多い傾向となった(表4) 。

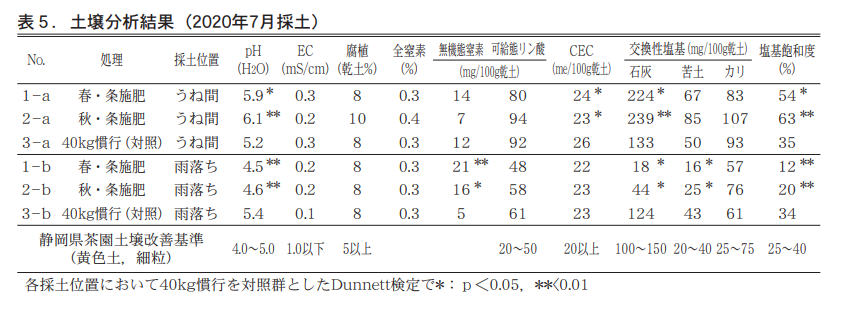

(5) The results of the soil analysis are presented in Table 5.

pHについては,春・条施肥区,秋・条施肥区ともに,うね間において茶園土壌改善基準を超過していた。交換性石灰含量についても春・条施肥区,秋・条施肥区ともにうね間では土壌改善基準を超過していた一方で,雨落ち部では不足していた。以上のことから,条施肥では慣行量(100kg/10a)の苦土石灰の施用を必要とせず,条施肥時に補填的に雨落ち部に投入することで,施肥回数の削減に繋げられると考えられた。また,春・条施肥区,秋・条施肥区ともに雨落ち部の無機態窒素量が多く,効率的な窒素吸収が行われている可能性が示唆された。

6)以上の結果より,春の条施肥,秋の条施肥ではともに生葉の収量増加,一番茶の摘芽窒素含有率の増加が期待できることが示唆された。特に秋の条施肥においては,春の条施肥以上に一番茶の収量及び窒素収奪量の増加が期待できると考えられた。また,土壌分析結果より,条施肥を行う際には苦土石灰の施用量を勘案する必要性が示唆された。

Summary

In this study, a test plot was set up in which 30 kg N/10a of a cover fertilizer was applied in late February or late August to a depth of about 5 cm in the rain-fall area of the tea plantation, and 10 kg N/10a of a fast-acting fertilizer was applied above the canopy in late March.

As a result, there was a trend of increased yield of fresh leaves and increased nitrogen content of plucked buds of first tea throughout the year in both test areas compared to the conventional area. In particular, the late-August strip fertilization tended to increase the yield and nitrogen deprivation of the first tea leaves more than the late-February strip fertilization. The results of soil analysis suggested that it is necessary to consider the amount and position of application of bitter lime when applying soil fertilizer.

However, care should be taken when applying fast-acting fertilizers to the entire area, because if rainfall after application is low, fertilizer nutrients may not be fully absorbed at the right time.

In order to spread the technology of strip fertilizer application in the future, it is necessary to continue further studies on machine development and work efficiency. In particular, in terms of machine development, it would be easier to spread the technology if it were developed as a riding-type attachment, considering cost and work efficiency.

Fertilizer-regulated fertilizer in two-row barley.

用いた全量基肥播種溝施肥法

Oita Agriculture, Forestry and Fisheries Research and Guidance Center

Agricultural Research Department, Paddy Field Agriculture Group

清田 梨華

Introduction

大分県では水稲乾田直播栽培の普及拡大に取り組んできており1),麦作で使用するドリルシーダを活用して播種し,播種溝へ肥効調節型肥料を施肥する技術(以下「ドリルシーダ播種溝施肥技術」と略する)を開発した。これにより,水稲作と麦作両方でのドリルシーダの汎用利用が可能になった。麦作での播種溝への施肥について,浦野ら(2012)は,慣行分施より肥効調節型肥料の全量基肥施肥の方が多収になることを報告している2)。しかし,近年麦の播種後に低温が続く年もあり,肥効調節型肥料の全量基肥施肥だけでは麦の初期生育を確実に確保できないことが懸念された。

Therefore, we investigated the possibility of improving the yield and quality of wheat by applying all the base fertilizer with a prototype fertilizer that combines a fast-acting fertilizer and a regulated fertilizer using the drill seeder seeding furrow application technique that we developed.

2. Methods

The trials were conducted in paddy fields (soil type: clay loam) at the Oita Prefectural Agriculture, Forestry and Fisheries Research and Guidance Center (8 m elevation, Usa City, Oita Prefecture) for three years from 2018 to 2020 sowing.

The test variety was Nishinohoshi, a two-row barley.

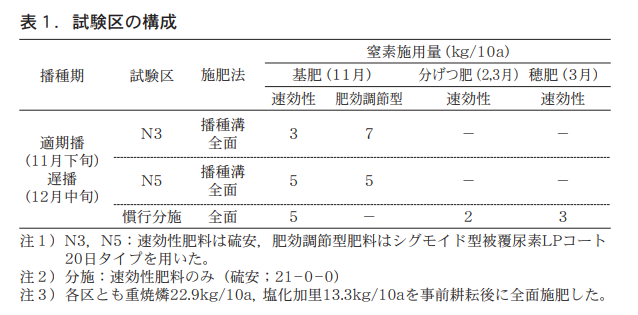

The composition of the test plots and seeding times are shown in Table 1. The test plots were divided into two types: a total basal application and a conventional partial application. In the total basal application, two types of granular compound fertilizers with different proportions of fast-acting and controlled-release fertilizers were applied in the seeding furrows and on the entire surface, respectively, for two replications in each test plot. Fertilizer materials were provided by JCAM Agri Co., Ltd. and the prototype fertilizers were formulated at the Oita Prefectural Agriculture, Forestry and Fisheries Research and Guidance Center.

The trial fertilizers consisted of ammonium sulfate as a fast-acting fertilizer and sigmoidal-coated urea LP-coated 20-day type (hereinafter referred to as "LPS20") as a controlled-release fertilizer. Two types of fertilizers were tested: a fast-acting fertilizer (fast-acting: controlled-release type) = 3:7 (hereinafter referred to as "Prototype Fertilizer N3"), which was applied as a priority fertilizer in the allotment, and a fast-acting fertilizer (controlled-release type) = 5:5 (hereinafter referred to as "Prototype Fertilizer N5"), which was applied in the same ratio as in the conventional allotment. In the conventional application, 5 kg of base fertilizer, 2 kg of compost, and 3 kg of ear fertilizer were applied per 10 a. In the conventional application, 5 kg of base fertilizer, 2 kg of compost, and 3 kg of ear fertilizer were applied per 10 a. The fertilizer N3 was applied to the entire surface of the crop.

Base fertilizer was applied on the sowing date, anthesis fertilizer at the 3- to 4-leaf stage of two-row barley, and ear fertilizer at the 2- to 5-mm length of young ears. In each test plot, phosphoric acid and potassium were applied at a rate of 22.9 kg/10a of phosphorus and 13.3 kg/10a of potassium chloride after pre-plowing.

In the seeding trench fertilizer application area, after the bed was erected, the compaction wheel of the drill seeder was removed and the soil covering device was lifted and fixed, after which the base fertilizer was manually applied to the seeding trench and the soil was covered. In the all-fertilizer-applied area, the base fertilizer was applied by hand to the entire surface of the field after the bed was erected, and the drill seeder was used for seeding, soil covering, and soil compaction, in that order.

Two sowing periods were set: mid-November to early December, which is the optimum sowing period in low elevation areas of the prefecture ("optimum sowing"), and mid-December to late December ("late sowing"), which is a later sowing period for large-scale management operations.

To investigate the nitrogen leaching rate of LPS20, a non-woven cloth containing 1 g of the fertilizer stock was buried at a depth of 10 cm from the ground surface in the test plots on the day of fertilizer application, and sampled 7 to 10 times until harvest. In each of the three years tested, three replications were applied, and nitrogen analysis of the samples was performed by the Fertilizer Research Laboratory of JCAM Agri Co.

The soil temperature of the field was measured at a depth of 10 cm from the soil surface at one-hour intervals between fertilization and harvesting using a temperature recorder (Model TR-52S Ondotori Jr. manufactured by T&D Co.

3. results

(1) Difference in growth progress between seeding furrow fertilization and conventional partial application

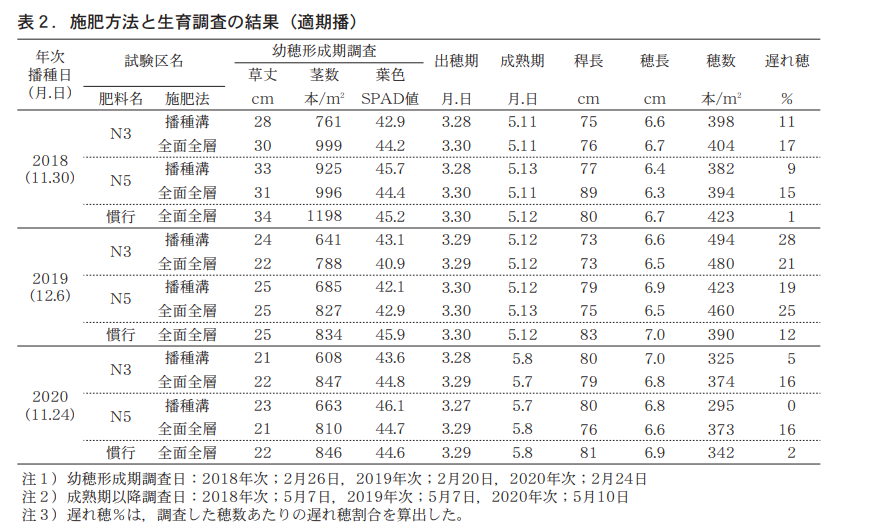

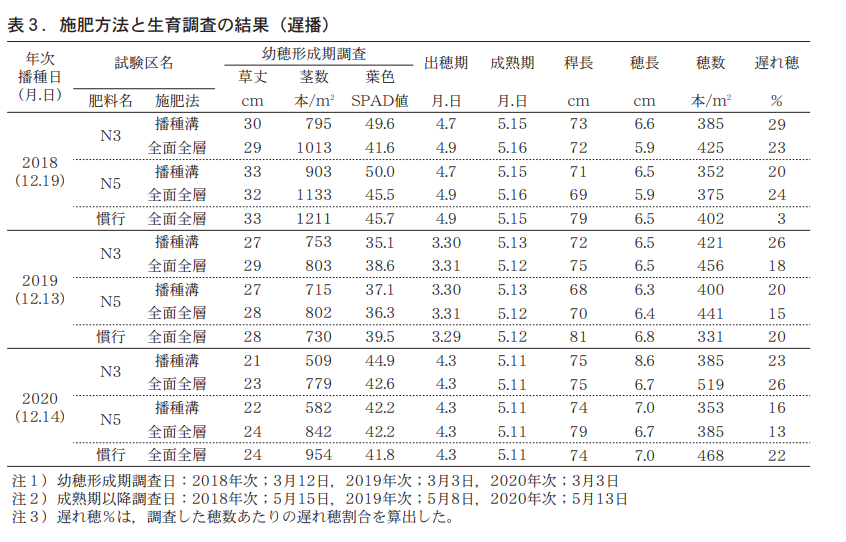

Fertilization methods and results of growth studies are shown in Tables 2 and 3.

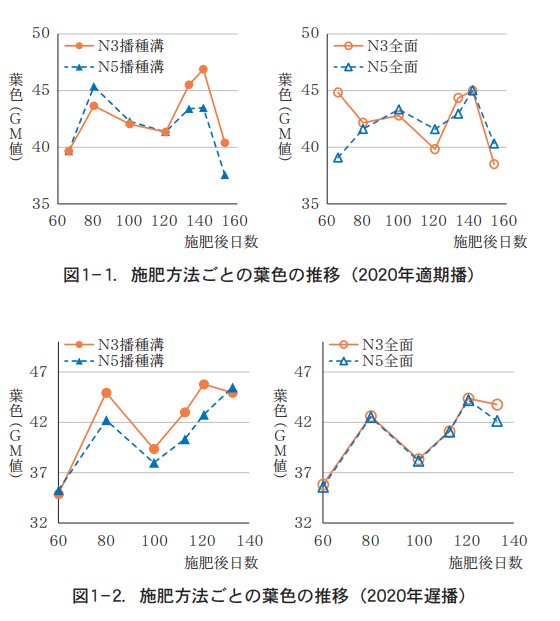

In 2020, the number of stems in the fertilizer application area tended to be lower than in the conventional area in both the early and late seeding areas. In 2020, leaf color in the N3 and N5 compartments became darker from 120 days after fertilizer application (Figures 1-1 and 1-2), confirming the leaching of nitrogen from the fertilizer with controlled fertilizer effect.

Culm length at maturity was similar to or slightly lower than that of the conventional partial application in both the timely and late sowing treatments, but ear length was slightly longer when the prototype fertilizer was applied in the seeding furrows than when the fertilizer was applied over the entire surface. The number of ears, like the number of stems, was lower when the seeding furrows were fertilized with the prototype fertilizer. However, in the 2019 sowing, strong winds and low temperatures before ear emergence caused sterile ears in both full- and late-seeding, and later ears occurred more frequently, resulting in a higher number of ears.

The percentage of late ears was higher in the late sowing and in the N3 trial fertilizer, where the proportion of fertilizer with regulated fertilizer was higher in the sowing furrow application.

(2) Yield difference between seeding furrow application and conventional partial application

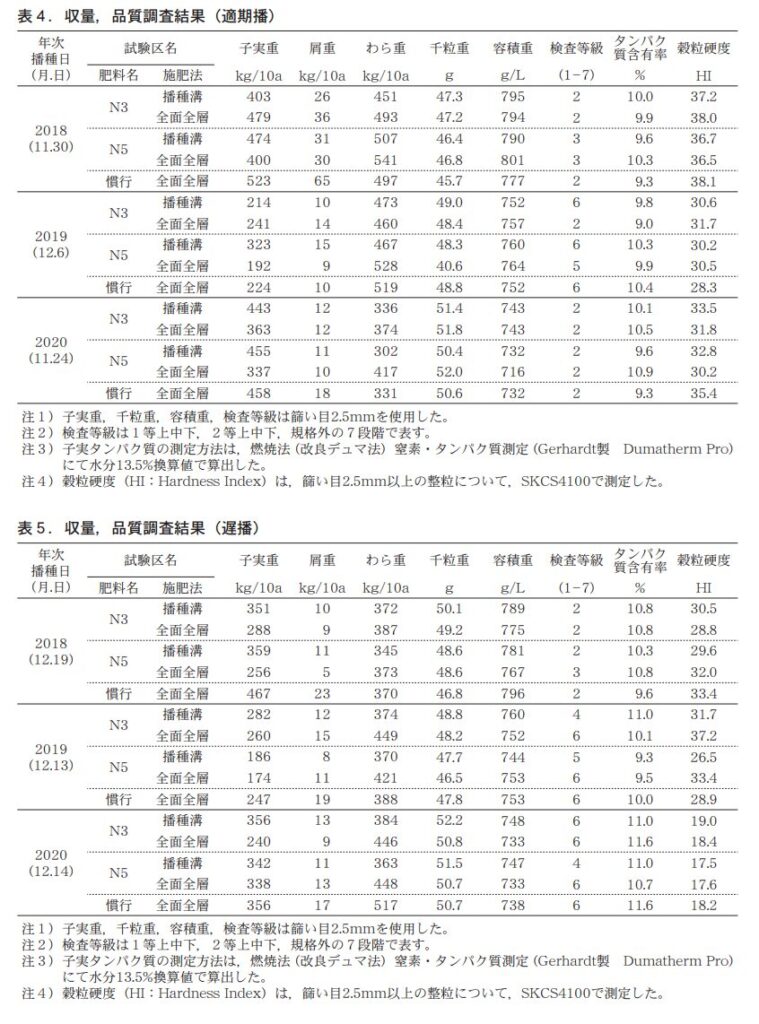

The results of the yield and quality surveys are shown in Tables 4 and 5.

In the timely seeding, when comparing the full application of the prototype fertilizer and the seeding trench application, the yield was higher in the seeding trench application except in the N3 plot of the prototype fertilizer in 2018 and 2019. Furthermore, when comparing the type of fertilizer applied in the seeding furrows, the yield was higher in the N5 plot with the prototype fertilizer than in the N3 plot with the prototype fertilizer, and the yield was almost the same as in the conventional partial application plot.

In the late seeding, the yield was higher in the seeding trench application compared to the full application of the prototype fertilizer and the seeding trench application. Furthermore, when comparing the type of fertilizer applied in the seeding furrows, yields were higher in the prototype fertilizer N3 than in the prototype fertilizer N5, except in 2018, when yields were generally similar to those in the conventional partial fertilizer application.

(3) Trends in nitrogen elution of LPS20

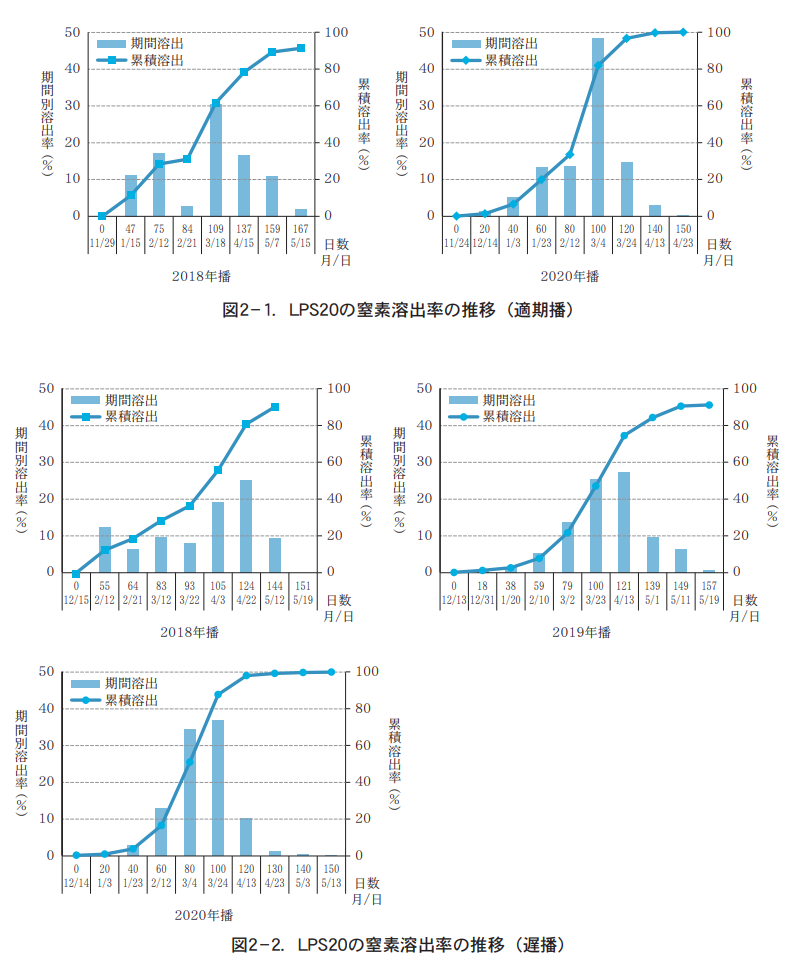

The nitrogen leaching of LPS20 buried in the test plots is shown in Figures 2-1 and 2-2.

The cumulative leaching rate of nitrogen began around the juvenile ear differentiation stage (early January) in the optimum sowing, and more than 801 TP3T was leached by the beginning of internode elongation (mid-April) in the 2018 sowing and by the juvenile ear formation stage (early March) in the 2020 sowing (Figure 2-1). In the late sowing, nitrogen leaching began around the juvenile ear differentiation stage (mid-January), and more than 80% was leached after the flowering stage (late April) in the 2018 and 2019 sowing, and by the earburst stage (late March) in the 2020 sowing (Figure 2-2).

The nitrogen leaching rate by the elapsed days after burial showed that the nitrogen leaching began to increase around 60 days after burial for both timely and late seeding, with the highest leaching around 120 days after burial for 2018 and 2019 seeding at 251 TP3T or higher, and the highest leaching around 100 days after burial for 2020 seeding at 371 TP3T or higher. The 2020 seeding had the highest elution of 37% or higher around 100 days after burial.

These results indicate that LPS20 leaches nitrogen from about 60 days after burial (early January for optimum seeding and mid-January for late seeding), and that LPS20 has a fertilizing effect as a runoff fertilizer and ear fertilizer.

Consideration

In this study, a total basal fertilizer application method with different ratios of fast-acting fertilizer and controlled-release fertilizer was examined for general use of the drill seeder seeding furrow fertilization technique developed for direct seeding of paddy rice in dry rice paddies in wheat cultivation.

Nitrogen leaching of LPS20, which was used as a trial fertilizer with regulated fertilizer efficacy, began around 60 days after embedding, and the highest nitrogen leaching occurred around 120 days after embedding in the 2018 and 2019 seedings and around 100 days after embedding in the 2020 seeding, depending on the year, but its effectiveness as a batch fertilizer or ear fertilizer was confirmed.

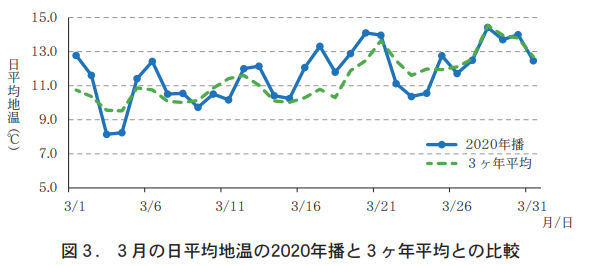

The reason for the earlier nitrogen leaching in LPS20 sown in 2020 compared to the other two years is that nitrogen leaching in LPS20 depends on soil temperature, and the daily average soil temperature from early March to late March in 2020 was 0.2 to 2.5°C higher than that in the three years, which causes a difference in nitrogen leaching. This is thought to have resulted in faster nitrogen leaching (Figure 3).

The effect of the prototype fertilizers on the yield of two-row barley was considered to be affected when the proportion of ammonium sulfate in the fast-acting fertilizer was low, as in the N3 plot, because the yield was not sufficient to ensure a sufficient number of offshoots by the young ear formation stage. In particular, the warmer-than-normal winter in the 2019 and 2020 sowing periods accelerated the growth of two-row barley, and sufficient fertilizer application in the first half of the growing season was considered necessary.

On the other hand, the prototype fertilizer containing ammonium sulfate and LPS20 at a ratio of 5:5 produced yields comparable to those obtained with the conventional partial application when sown at the right time. However, in the case of late seeding, nitrogen leaching of LPS20 peaks from late March to mid-April, resulting in an increase in late ears and a decrease in quality.

Based on the above, it was considered possible to use the total basal seeding furrow fertilization method for two-row barley by using a fertilizer with a 5:5 ratio of ammonium sulfate to LPS20 and seeding in mid-November to early December.

When the prototype fertilizer used in this study was applied to wheat, which has a later ear emergence and ripening period than barley, the nitrogen release period of LPS20 and the timing of wheat fertilizer application could be expected to be almost identical.

Acknowledgements

We would like to express our sincere thanks to Mr. Kawakami and Mr. Tsuchiya of the Kyushu Branch of JCM Agri Co., Ltd. and Mr. Tanaka of the Fertilizer Research Laboratory of JCM Agri Co. for providing the trial fertilizer and conducting the nitrogen analysis of the LPS20 leaching test.

works cited

(1) Oita Prefecture guidelines for direct seeding of paddy rice in dry rice paddies. 2020.

2)浦野浩一郎.2012.肥効調節型肥料の全量基肥播種溝施用が裸麦の生育,

収量および品質に及ぼす影響.日作中支集録52.

土のはなし−第11回

堆肥は養分移転資材として登場した

−養分の補給方法を考える−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Starting with this issue, "No More Soil" will be renewed. In the past 10 articles, we have discussed the four conditions for good soil for crops. In the next 10 articles, we will discuss compost, chemical fertilizers, organic farming, and the role of soil. This time, we will look back at the history of compost, which was invented and used to replenish farmland with nutrients in the days before chemical fertilizers were available.

1. nutrient replenishment is necessary to maintain soil fertility

It is believed that humans began farming about 10,000 years ago. Since then, when crops are grown and harvested on farmland, the nutrients in the soil are absorbed by the crops and taken out of the farmland with the harvest. If nutrients are not replenished, the crop nutrients in the soil will be depleted and the crop cannot be grown. Therefore, replenishment of nutrients was essential for the sustainable cultivation of crops on farmland.

How exactly to supply nutrients was the main concern. The only way to recover nutrients from the soil was to collect materials around us, such as leaf litter from forests, mud from rivers and lakes, fallen leaves, fallen branches, underbrush from forests, wild grasses, grass and tree ashes, seaweed, and manure from people and livestock. This nutrient transfer process was very labor intensive and time consuming.

2. compost conceived as a nutrient transfer material

土の中にある作物の養分を回収し,回収した養分を別の場所に移動するために考え出された最強の資材,それが堆肥だった。土の中の養分の回収方法には二つあった。一つは従来どおり農地の外で育つ植物(野草や雑草など)を刈取ったり,落葉や落枝,さらに山林の下草などを収集して,それらを堆積,分解させて堆肥化する方法である。もう一つは,飼料になる植物(野草や牧草)をエサとして家畜に採食させ,その植物が吸収した土の中の養分を家畜のふん尿の形で回収して堆肥化するやりかたである。

European farmers, in particular, realized that the use of livestock was much more labor-saving than collecting materials from outside the farmland. Therefore, they actively promoted nutrient recovery and composting through the use of livestock and developed a crop rotation system. The culmination of these efforts was the four-year crop rotation known as the Norfolk farming method.

3. intensive crop rotation before the advent of chemical fertilizers

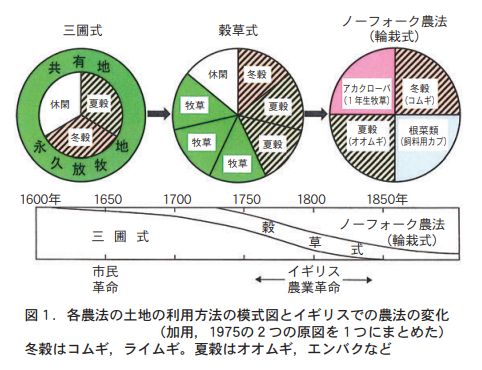

ヨーロッパでの輪作の初期は単純に農地を二分し,一方は作物栽培に用い,他方は作物栽培を休む(休閑という)ことで,土の中の養分の回復を自然にまかせるという二圃式輪作であった。その後,三圃式,穀草式と発展し,ノーフォーク農法(輪栽式)にたどり着いた(図1) 。

Earlier crop rotations also used manure from livestock grazing on common land or permanent pasture. However, keeping livestock on pasture or grassland had the disadvantage that the collection rate of livestock manure excreted from the pasture or grassland decreased. In addition, the growth of wild grasses and pastures declines during the fall and winter, making it difficult to secure sufficient forage to overwinter livestock.

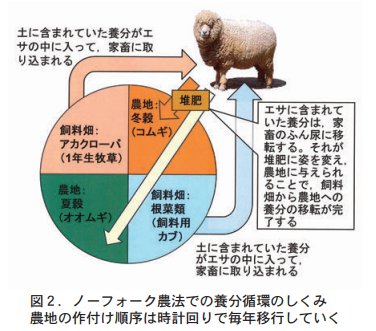

ノーフォーク農法は共同放牧地と休閑をすべて廃止して農地を拡大し,家畜の飼料となる2種類の作物(飼料用根菜類=飼料用カブ,マメ科牧草=アカクローバ)を4年輪作の中に組み入れて飼料生産を確保した。飼料用カブの播種には農事改良家のタルが開発した条播機を利用する条播栽培が導入された。それによって,雑草防除のための中耕が可能となり,飼料用カブの生産が安定するようになった。アカクローバには根に共生する根粒菌による窒素固定が見込まれ,土の窒素肥沃度を高めるのに有効だった。こうしたことから飼料生産量が多くなり,家畜の多頭飼養と冬期でも舎飼いが可能となった。家畜の舎飼いはふん尿の回収率を高め,堆肥生産量が飛躍的に増えた。このため,穀物生産畑への堆肥施与量が多くなって,土の養分肥沃度が高く維持できるようになった(図2)。こうして,家畜ふん尿を利用した養分循環に基づく農法が確立し,当時としては超集約的な輪作が実現した。

There is a saying in the Flemish region of mainland Europe across from Norfolk, England (present-day southern Netherlands to western Belgium and northern France): "Without feed there is no livestock, without livestock there is no fertilizer, and without fertilizer there is no harvest. This saying eloquently describes the major role of manure as a nutrient transfer material for maintaining crop production in European crop rotation.

ノーフォーク農法はコムギ生産量を一変させた。ノーフォークはイングランド(イギリスの4つの構成王国のうちの一つ)の面積の4%しかない小さな地域であるのに,ノーフォーク農法の導入で,コムギ子実生産量は当時の全イングランドの90%をまかなったという(飯沼,1967)。

4. Japanese View of Composting: Tradition of the Supremacy of Mature Compost

わが国の主食はコメである。そのコメはイネから生産され,イネは水田で栽培される。水田はイネが収穫されても,イネが吸収した養分のかなりの部分が自然に回復するという素晴らしい仕組みを持っている。例えば,かんがい用水に含まれている養分によって自然に養分が補給される。それだけでなく,水田に水をたくわえることでリンや鉄が,水に溶けやすい形態(水溶性)に変化してイネに吸収される。その他さまざまな要因のおかげで,水田は養分の自然供給量が多くなる。このため,畑の土に比べると作物栽培による養分の消耗程度が小さい。このことは,19世紀のノーフォーク農法絶頂期のコムギ子実収量が1.7t/ha程度だったのに対して,太閤検地のおこなわれた16世紀末で,イネの子実収量はすでに1.8t/haと,ノーフォーク農法のコムギとほぼ同等の収量をあげていたことからも理解できる(髙橋,1991)。

わが国の農業では,家畜は労力として主に利用された。したがって,農家が飼養する家畜頭数はわずかで,堆肥づくりに家畜のふん尿を含めず,イナワラやムギワラを堆積して腐熟化させて生産されるのが一般的だった。家畜ふん尿を含まないこれらの堆肥は完全に腐熟した完熟堆肥でなければ,養分としての効果が現れにくい(その理由については,後ほど説明する予定)。わが国で,「堆肥を使うなら,完熟堆肥でなければならない」という完熟堆肥至上主義が強調されるのは,このような伝統が受け継がれた結果ではないだろうか。わが国の水田農業とヨーロッパの養分循環型農業との本質的なちがいを感じ取ることができる。