Site Search

Search within product

第753号 2023 (R05) .08-09発行

Click here for PDF version

農業と科学 令和5年8-9月

本号の内容

§ High-density seeding in paddy rice and

育苗箱全量施肥栽培を組み合わせた省力技術

Kumamoto Prefectural Agricultural Research Center, Production Environment Research Institute

Soil Environment Laboratory

田中 一成

§イチゴ「あまおう」の育苗期における省力的施肥法

Fukuoka Prefectural Agriculture and Forestry Experiment Station, Chikugo Branch

龍 勝利

§土のはなし-第24回土は環境の産物である

-風化と生物の作用が岩石から土をつくる

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

High-density seeding in paddy rice and

育苗箱全量施肥栽培を組み合わせた省力技術

Kumamoto Prefectural Agricultural Research Center, Production Environment Research Institute

Soil Environment Laboratory

田中 一成

Introduction

Rice cultivation in Kumamoto Prefecture is no exception to the recent severe situation, with stagnant rice prices and a growing shortage of rice farmers. One of the agricultural policies to solve these problems is the development and practical application of technology that contributes to the consolidation of farmland through the expansion of management scale and the accompanying reduction of production costs and labor hours, which is expected to lead to improved rice farming management.

Currently, high-density seeding technology and whole seedling box fertilization technology are attracting attention as low-cost and labor-saving cultivation technologies for paddy rice that have been put into practical use. The former is a technology that significantly reduces the number of seedling boxes required by increasing the amount of seeding per seedling box and removing a small amount of fertilizer. The latter is a fertilization method in which the amount of nitrogen necessary for growth is applied in the seedling box at the time of sowing, and the fertilizer is held by the paddy rice seedlings before transplanting. Both of these techniques have already been adopted as low-cost and labor-saving cultivation techniques for paddy rice by some large-scale farmers in the prefecture.

This paper describes the results of research conducted to clarify the effects of the combination of high-density seeding and whole seedling box fertilization on seedling quality, growth, and yield of paddy rice, with the aim of further reducing costs and saving labor by combining these two technologies, which have been separately practiced.

2. Testing Method

(1) Seedling quality test

Seedling transplanting tests were conducted under the assumption that the seedlings would be transplanted by machine in the middle of June, which is the standard transplanting time for normal-season cultivation in Kumamoto Prefecture. Two levels of seedling production were used: conventional seedling production (hereinafter referred to as "conventional") and a combination of high-density seeding and full fertilizer application to seedling boxes (hereinafter referred to as "high-density seeding with box fertilizer"). The rice variety was Hinohikariʼ, and the trial was conducted for two years from 2020 to 2021. The seeding rate was 100 g (dry matter equivalent) per box in the conventional level, and 250 g (dry matter equivalent) per box in the high-density seedling box fertilization level. In the conventional area, commonly used 30-mm-deep medium seedling boxes were used.

In the high-density seedling box fertilization zone, seedling boxes with a depth of 40 mm (manufactured by Sanko Co., Ltd.) were used, and 2,250 g of "Seedling Box Makase® N400-120" per box was applied to the bottom of the box. During the seedling growth period, the seedlings were irrigated by hand with top irrigation. As a common practice, commercially available artificial granulated soil (Hinokuni soil manufactured by Ryoto Fertilizer Co.

Seedling height, stem, leaf and root dry matter weights, seedling weight per box, and root mat strength were examined immediately prior to transplanting in both locations.

(2) Measurement of seedling weight per box at sowing and transplanting

The weight of seedlings (including the weight of the seedling box) per box at sowing was measured after filling the seedling box with bedding soil or seedling box material, irrigating, sowing, covering with soil, irrigating again, and allowing the seedlings to rest until gravity water had sufficiently drained out. The weight of seedlings per box at the time of transplanting was measured after irrigating the seedlings before measuring the weight and allowing the seedlings to rest until the gravity water had completely drained out.

(3) Seedling root mat strength survey method

The center of the seedling was cut at right angles to the cross section (28 cm) with a width of 10 cm, and clips (at least 10 cm wide) were fixed to both short sides.

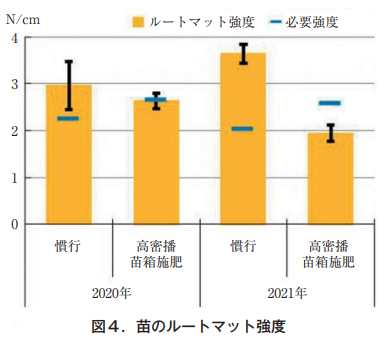

The standard root mat strength that does not interfere with machine transplanting operations is 1.8 N/cm or higher in a normal seedling box with a depth of 30 mm, but this strength varies depending on the weight of the seedlings. However, this strength varies depending on the weight of the seedlings. Since a seedling box with a depth of 40 mm is used here, the weight of the seedlings is heavier, and the root mat strength is considered to be affected. Therefore, it is necessary to check whether the root mat has sufficient strength when transferring seedlings grown in a 40 mm-deep seedling box to the seedling bed of a rice transplanter.

Therefore, we determined the required strength of a seedling per cm of seedling width, which is equivalent to holding the seedling in one hand, using the formula: required strength (N/cm) = weight of seedling after seedling growth (kg) / length of seedling cross section (28 cm) x moment of force (9.8 m/s²), and compared this to actual measured values.

(4) Cultivation test

Cultivation trials were conducted to determine the effects of the technology combining high-density seeding and full seedling box fertilization on the growth and yield of paddy rice in the rice paddies.

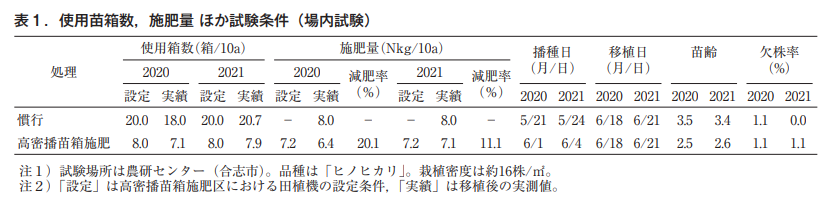

Table 1 shows the details of the in-house trials. The test area consisted of two levels: a high-density seedling box fertilization area in which 2,250 g of "Seedling Box Makase® N400-120" was applied to the bottom of the box at a seeding rate of 250 g (dry matter equivalent) per box, and a conventional area in which seedlings were raised at a seeding rate of 100 g (dry matter equivalent) per box. In the former, fertilizer was applied to the rice paddies. In the former, no fertilizer was applied to the seedlings and they were transplanted directly, while in the latter, all the base fertilizer was applied with LP-coated compound fertilizer, and then the seedlings were transplanted in the middle. The amount of nitrogen fertilizer applied was 7.2 kg/10a in the high-dense seedling box fertilization area, assuming the number of seedling boxes used was 8, and 8 kg/10a in the conventional area, respectively.

To confirm its applicability in the field, we conducted a cultivation test similar to the in-field test. The test site was a paddy field in Taragi Nobiru (Taragi Town, Kuma County, Kumamoto Prefecture), and the variety was 'Hinohikari'. The seedlings were sown on May 25, 2021 and transplanted on June 10, 2021. In the high-density seedling box fertilization area, 2,025 g of "Seedling Box Makase® N400-120" was applied to the bottom of each box at a seeding rate of 300 g (wet weight) per box. In the conventional method, seedlings were grown at a rate of 100 g (dry matter equivalent) per box of seeding, and all fertilizer was applied as basal fertilizer. Nitrogen fertilizer was applied at a rate of 8.1 kg/10a in the high-density seedling box fertilization area and 9 kg/10a in the conventional area.

Results and Discussion

(1) In-situ testing

(1) Seedling length and fullness

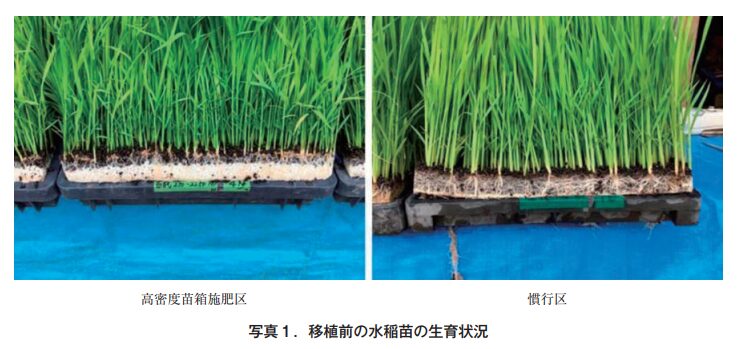

Seedlings were grown for 17 days in the high-density box-fertilized area and for 28 days in the conventional area, and seedlings with no problems in terms of appearance were successfully grown (Photo 1). The most important factors in determining whether paddy rice seedlings are suitable for transplanting by machine are seedling length and rootmat strength.

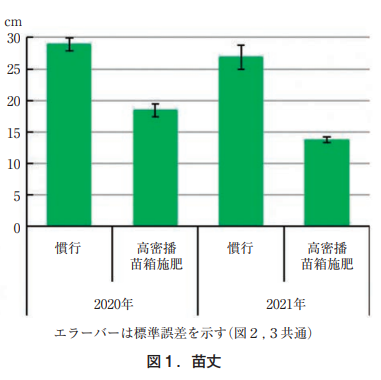

The seedling height range of 10 to 25 cm is considered suitable for machine transplanting, considering that the transplanter can transplant without difficulty and the transplanted seedlings are not submerged in water. As shown in Figure 1, seedling height in the high seeding box fertilized area was lower than that in the conventional area in both years, but seedling height in the high seeding box fertilized area was in the range of 13 to 19 cm, which was sufficient for machine transplanting.

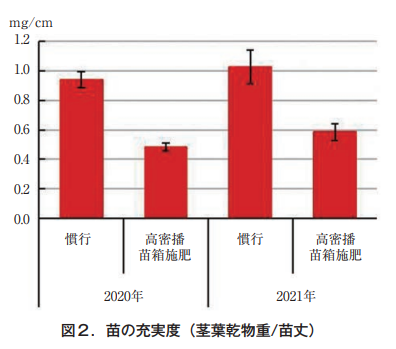

On the other hand, the seedling enrichment (stem and leaf dry matter weight/seedling height) was lower in the high seedling density box-fertilized area than in the conventional area in both years (Figure 2), presumably because the seedlings were grown for 10 days shorter than in the conventional area.

(2) Seedling weight per box and root mat strength

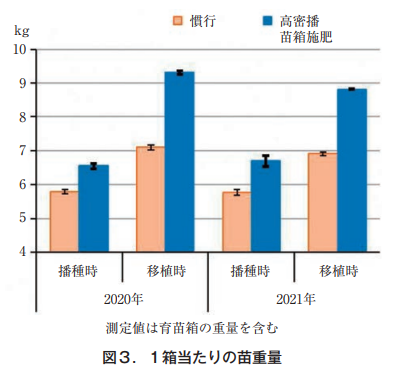

Seedling weight per box was approximately 1 kg heavier in the high-density seedling box-fertilized area at sowing and approximately 2 kg heavier at transplanting than in the conventional area (Figure 3). This was considered to be due to the fact that the seedling boxes used in the high-density seedling box fertilization area were deeper than those used in the conventional area, which increased the amount of soil and moisture retention.

The strength of the root mats was sufficient for the conventional area, but less than the required strength for the area with the high density seedling box fertilizer (Figure 4). In fact, in the conventional area, it was possible to hold a seedling removed from the seedling box with one hand, but in the high-density seedling box fertilization area, it was not possible to hold the seedling even with both hands. This may be because the root mat was not strong enough to withstand the weight of the seedlings themselves due to the increased overall weight of the seedlings in the high-density seedling box fertilization area, where 40 mm-deep seedling boxes were used. However, it was confirmed that the seedlings could be moved to the rice transplanter by using the seedling pick-up board, and there was no problem in transplanting work in the rice field.

(3) Growth and yield in the main field

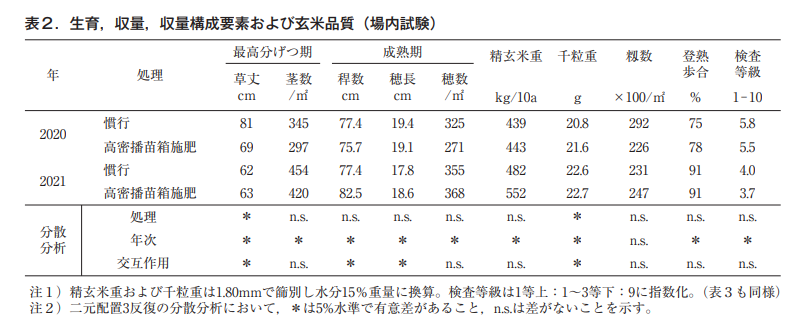

In the 2021 trial, grass height was similar and the number of stems was slightly higher in the conventional treatment than in the high-density seedling box fertilization treatment. Culm length, ear length, and ear number at maturity were similar in both years.

Yield (milled brown rice weight) was higher in the high-density seedling box-fertilized area than in the conventional area in both years. In terms of appearance quality (inspection grade), the high-density seedling box fertilizer application area showed superior quality compared to the conventional area in both years (Table 2).

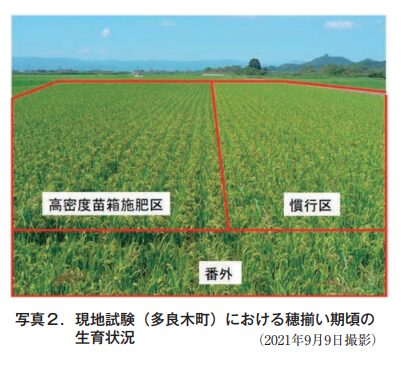

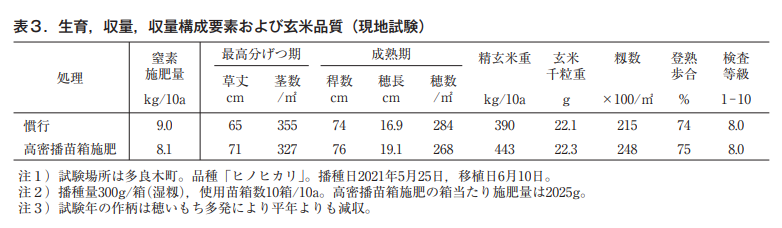

(2) On-site testing

In the field (Taraki Town), grass height was lower in the conventional plot at the highest stage of the maximum height stage, but the number of stems was higher.

At the ear-planting stage, the color of standing hairs in the high-density seedling box-fertilized area was darker green than that in the conventional area (Photo 2). At maturity, ear length was longer in the high-density seedling box-fertilized area, but the number of ears was higher in the conventional area. Yield (weight of polished brown rice) was higher in the high-density seedling box-fertilized area than in the conventional area, and there was no difference in appearance quality (inspection grade) (Table 3).

Summary

As described above, using seedling boxes with a depth of 40 mm and combining high-density seeding with total fertilizer application to the seedling boxes (box-bottom fertilization), it was possible to produce seedlings of good quality that would not interfere with transplanting operations. This reduced the number of seedling boxes used per 10a to eight, eliminating the need to apply fertilizer to the rice paddies and suggesting that labor-saving cultivation is possible with a 10% reduction in nitrogen fertilizer compared to the conventional fertilizer application.

The following points should be kept in mind when utilizing the labor-saving technology combining high-density sowing and whole seedling box fertilization introduced in this paper.

(1) It is necessary to confirm that the sowing machine is adaptable to seedling boxes 40 mm deeper than normal.

②水稲根への水と酸素の供給を良くするため,育苗法は畑育苗を推奨する。ただし,慣行育苗よりも床土量が少なく乾燥しやすいため,苗が萎れない程度に1日の潅水回数を増やす必要がある。

③苗の充実度が低くなりやすいので,出芽後の被覆シートを苗丈1cm程度で取り除くなど,充実した苗を作る管理を行う。その他,育苗箱全量施肥栽培に対する基本的な育苗管理を遵守するとともに,初めて取り組む場合には予め小規模で試作することが望ましい。

④高密度苗箱施肥栽培では,苗重量が重いため十分なルートマット強度が得られない場合が予想されるが,苗取板を用いれば移植作業は支障はなく実施できる。

⑤移植に際しては高密度播種対応田植機を用いるとともに,面積当たりの使用箱数が本田施肥量に関係するので,横送り回数とかき取り量(高さ)による面積当たり使用箱数の正確な設定が必要である。

Labor-saving fertilization method for strawberry "Amao" in seedling stage

Fukuoka Prefectural Agriculture and Forestry Experiment Station, Chikugo Branch

龍 勝利

Introduction

The strawberry "Amao" (variety name: Fukuoka S6), bred at the Fukuoka Prefectural Agriculture and Forestry Experiment Station, is produced only in Fukuoka Prefecture, with a planted area of approximately 300 ha (in 2022), and 100% of the strawberries sold through the joint marketing of the strain are "Amao". As the name "Amaou" (meaning "big, round, large, and delicious") implies, the fruit is characterized by its red, glossy, large size, and well-balanced sweetness and acidity. For this reason, it is extremely popular not only among consumers nationwide, but also among professional chefs, and the market demands a stable production and supply.

Compared to other fruits and vegetables, strawberries require more seedlings to be planted and more labor for seedling production due to their nutritional reproduction. In addition, it is necessary to control the growth and flowering of seedlings during the seedling growth period through fertilizer management. Specifically, it is necessary to supply sufficient nitrogen for growth during the first half of the seedling training period, while in the second half of the seedling growth period after late August, nitrogen supply should be stopped to promote flower bud differentiation and reduce the nitrogen concentration in the body of the seedlings (Uematsu, 1998).

「あまおう」の場合,窒素量を約70mg含む固形肥料を3回程度施肥し,窒素が不足する場合は液肥で補うのが一般的である(福岡県農林水産部経営技術支援課,2020)。しかし,育苗時の追肥作業は7月から8月の高温期に行われ,10a当たり約8,000株の苗に複数回の施肥を行わなければならず,生産者にとって重労働であるため,省力化が望まれていた。

In order to reduce the labor-intensive burden of fertilizer application, we investigated a system in which all fertilizer is applied at once using a slow-release coated fertilizer with adjustable leaching rate and duration of fertilizer components. Here, we introduce the outline of the system.

2. Methods

(1) Fertilization method

A two-year trial was conducted in 2019 and 2020 comparing a single application of slow-release coated fertilizer (hereafter referred to as "total fertilizer") and four applications of solid fertilizer (hereafter referred to as "conventional").

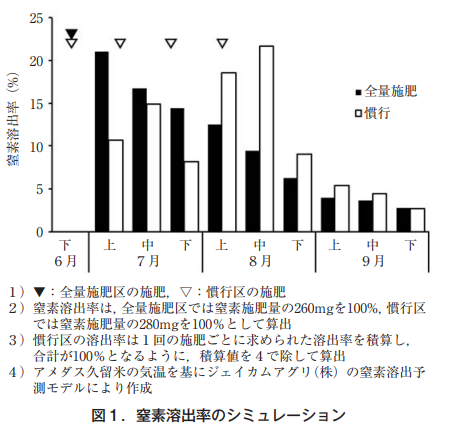

Based on the leaching simulation of coated fertilizers (Figure 1), Ecolong Total 391-70 type, a linear coated phosphorus nitrate-alkali (N:P₂O₅, K₂O=13:9:11%, Jaycam Agri Co: K₂O=13:9:11%, Jaycam Agri Co. For the total fertilizer application, a potting fertilizer (Shot-kun, Matsumoto Co., Ltd.) was used (Fig. 2). Fertilizer application for the total fertilizer application was conducted on June 24, 2019 and June 25, 2020, at a rate of 2 g/pot (260 mg nitrogen/pot).

IB Kasei S No. 1 (N: P₂O₅: K₂O = 10:10:10%, Jaycam Agri Co.) was used as fertilizer in the conventional plot. Fertilizer applications in the conventional zone were made on June 24, July 8, July 22, and August 5 in 2019 and on June 25, July 8, July 22, and August 5 in 2020, with one grain per application, for a total fertilizer rate of approximately 2.8 g/pot (280 mg nitrogen/pot).

(2) Seedling raising method

Seedlings were collected by the potting method, and seedling culture medium was strawberry medium No. 2 (N: P₂O₅: K₂O = 100: 400: 50 mg/L, Seishin Sangyo Co., Ltd.) containing palm peat and charcoal. Seedlings were managed under rain-shielded conditions. No liquid fertilizer was applied to the seedlings during seedling growth. Seedlings were irrigated 1 to 3 times/day during seedling growth, depending on weather conditions. Leaves were harvested every two weeks from the beginning of July to obtain 3.0 to 3.5 leaves remaining in the seedlings.

(3) Cultivation method after seedling planting

イチゴの栽培には単棟ビニルハウス(間口6m,奥行き20m)を用いた。栽植様式は畝幅120cm,条間50cm,株間25cmとし,2条内なりの土耕栽培とした。定植は2019年では9月24日,2020年では9月23日に行った。

For the base fertilizer, 10 kg/10 a of nitrogen was applied with a special Amao fertilizer (N:P₂O₅:K₂O=8:6:3%, Dainippon Sangyo K.K.), which contains organic matter and coating nitrogen. In late October, 5 kg/10 a of nitrogen was applied as additional fertilizer to the seedlings, respectively, with a special fertilizer for Amao and Super Ecolong 413-140 (N:P₂O₅:K₂O=14:11:13%, JCAM Agri Co.

Mulch cover was applied on October 18 in 2019 and October 26 in 2020. Overhead vinyl cover was applied on October 29 in both years, and the plants were heated with a hot-air heater to prevent the minimum nighttime temperature from falling below 5°C. The irradiation was interrupted during the dark period. Electricity was applied from November 15 to February 28 in 2019 and from November 15 to February 18 in 2020, for 2 to 4.5 hours, depending on the vigor of the grass.

3. results

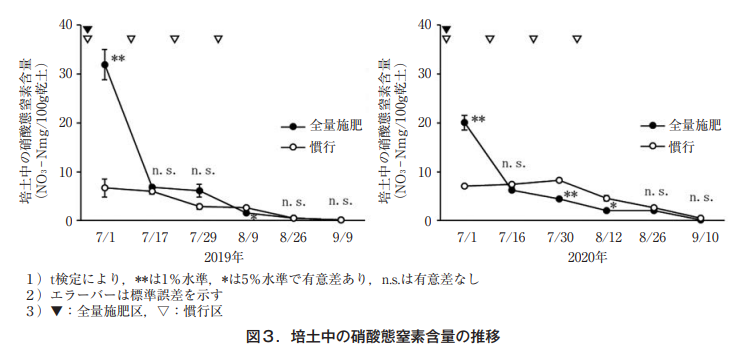

(1) Nitrate nitrogen content in the medium

The nitrate nitrogen content in the medium during the seedling growth period is shown in Figure 3, and in both years, the nitrate nitrogen content in the medium was 13-25 mg/100 g dry soil in early July in the total fertilizer application area, 1-3 mg/100 g dry soil in mid-August, and no difference was observed after late August and remained below 3 mg/100 After the end of August, no difference was observed, and the dry soil content remained below 3 mg/100 g dry soil.

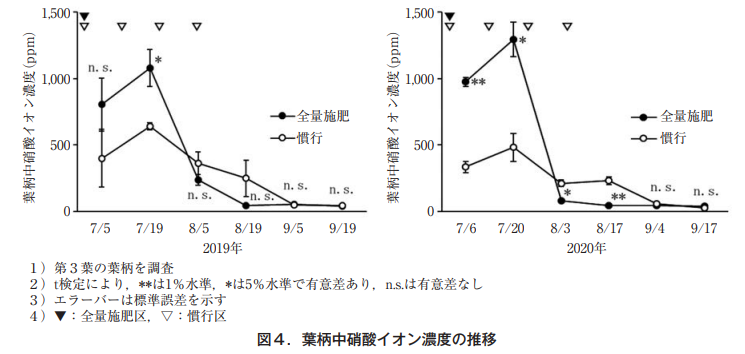

(2) Nitrate ion concentration in petioles and flower bud differentiation

Figure 4 shows the trends of nitrate ion concentrations in petioles during the seedling growth period. Nitrate ion concentrations in petioles in the total fertilizer-applied area were higher than those in the conventional area, exceeding 1,000 ppm in mid-July, and were generally 40 to 50 ppm from mid-August onward, remaining at the same level or lower than those in the conventional area. The flower bud differentiation index in the total fertilizer-applied area did not differ from that in the conventional area in both years (data omitted).

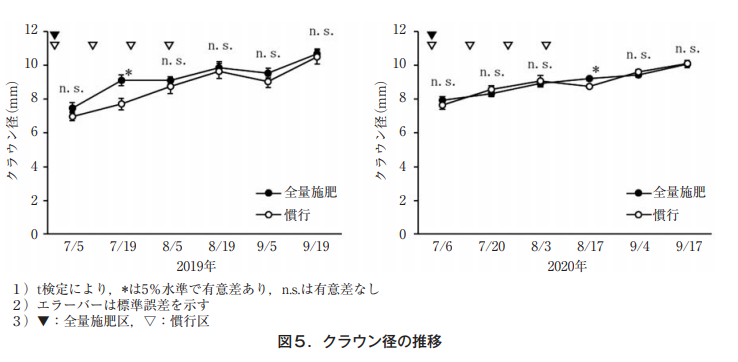

(3) Growth during seedling stage

Trends in crown diameter are shown in Figure 5. In 2020, the crown diameter was larger on August 17 in the total fertilizer application area than in the conventional area, but there was no difference at other times. Thus, there was no consistent trend between the two years when differences in crown diameter occurred, and no difference was observed at the end of September during the planting period, when both areas were about 10 mm in diameter. Petiole length and leaf width of the third leaf were 6 to 7 cm and 5 cm, respectively, at the end of September when the plants were planted, and there was no difference between the two test sections (data not shown).

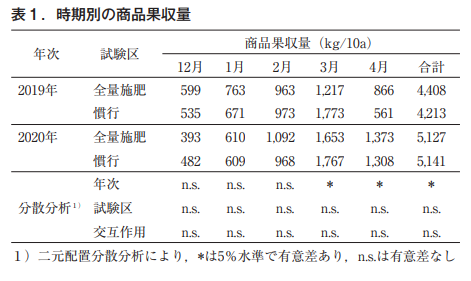

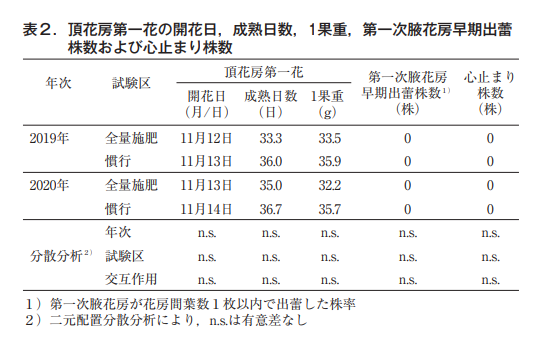

(4) Effect on fruit yield and flower cluster

Product yields at different times of the year are shown in Table 1. There were no differences in the commercial fruit yields among the test sections at any time of the year. Flowering date, days to maturity, one-fruit weight, number of early budding plants of the first axillary flower, and number of heart stopping plants of the first flower of the apical bunch are shown in Table 2. No differences were observed between the two test sections. In both years, no early budding or dead center plants of the first axillary flower cluster were observed in both locations.

(5) Cost estimates for different fertilization methods during seedling growth

全量施肥区の資材費は,肥料費 5,100円に鉢物用定量施肥器の年間償却費 2,100円(商品価格15,000円を耐用年数7年として算出)を加えた7,200円であった。慣行区の資材費は肥料費の4,400円であっ(データ略)。全量施肥区の資材費は慣行区に比べて2,800円高かった。一方,10a当たりの施肥作業時間は,全量施肥区では4.7時間(施肥回数1回)となり,慣行区の18.7時間(施肥回数4回)に比べて14時間削減された(データ略)。この施肥作業時間から算出した労賃(1時間当たり自家労働評価額1,460円;福岡県農林水産部調べ)は,全量施肥区では6,900円,慣行区では27,300円で,全量施肥区は慣行区に比べて20,400円安かった。

The total cost of materials plus labor was estimated to be 14,100 yen for the total fertilizer application area and 31,700 yen for the conventional area, a reduction of 17,600 yen for the total fertilizer application area compared to the conventional area.

Consideration

When the average temperature of strawberry plants drops to around 25°C from late summer to early autumn, flower bud differentiation occurs in response to the shortened day length (Honda 1977). However, if the nitrogen content in the seedling medium is high, flower bud differentiation will be delayed even under short day length conditions (Yasumatsu and Kimura 1981). Therefore, different fertilizer management is needed for the first half of seedling growth, in which an appropriate amount of nitrogen is provided to produce fuller seedlings, and for the second half, in which flower bud differentiation is induced by nitrogen interruption.

In this test, the nitrate nitrogen content in the seedling medium of the fully fertilized area was 13-25 mg/100 g dry soil in early July compared with the conventional area, but no difference was observed after late August, and the nitrate nitrogen content remained below 3 mg/100 g dry soil. These results suggest that more nitrogen was supplied to seedlings in the total fertilizer application area in the first half of seedling growth in early July than in the conventional area, and the same level of nitrogen was supplied to seedlings in the latter half of seedling growth from late August onward as in the conventional area. In fertilization management in the latter half of seedling growth, it is important to interrupt nitrogen supply from mid-August to induce flower bud differentiation smoothly, and to keep the nitrate ion concentration in petioles below 100 ppm, which is a standard for nitrogen concentration in the body (Morishita 2014).

On the other hand, it has been reported that flower bud differentiation and development are rather suppressed when extremely low nitrogen conditions are applied from around early September (Yoshida et al. 2002). In addition, when the nitrate ion concentration in petioles at the planting stage falls below 10 ppm, early budding of the first axillary flower cluster and heart-stopping plants are likely to occur (Takeuchi and Sasaki 2008). Therefore, it is considered necessary to maintain the nitrate ion concentration in petioles in the range of 10 to 100 ppm from mid-August to late September to avoid reducing the nitrogen concentration in the body too much in the latter half of seedling growth.

In this test, the nitrate ion concentration in petioles of the total fertilizer-applied area was above 1,000 ppm in late July in both years, but after mid-August, the concentration remained at 40 to 50 ppm, similar to or lower than that of the conventional area. In the total fertilizer-applied area, no delay in flower bud differentiation was observed at planting time, and no early budding or heart-stopping plants were observed after planting. These results suggest that even if the nitrate concentration in petioles of "Amao" was 1,000 to 1,300 ppm in late July, flower bud differentiation was not delayed and flower bud differentiation could be induced around September 20 to 25 if the nitrate concentration was controlled at 40 to 50 ppm from mid-August onward.

However, the coated fertilizer used in the total fertilizer application is designed to accelerate nitrogen leaching under high temperature conditions (Gunjikake 2020); therefore, when temperatures in June to August are higher than normal, nitrogen leaching is accelerated in the total fertilizer application method, and there is concern that nitrogen may become insufficient in the latter half of seedling growth. In such cases, it is necessary to pay attention to prevent the nitrate ion concentration in petioles from decreasing too much in the latter half of seedling growth, for example, by using liquid fertilizer to add fertilizer.

Because seedling size and nutritional status at the time of planting affect yield after planting, the goal for "Amaou" is to grow seedlings with crown diameters of 8.5 to 10 mm and short petioles that do not grow long (Fukuoka Prefecture Horticultural Promotion Council 2006). Seedlings in the total fertilizer application area in this study had seedling quality comparable to that of the conventional area at planting time in late September, with crown diameters of 10 to 11 mm. In the post-planting survey, no difference was observed in the flowering date of the first flower of the apical flower cluster or in the yield after planting in the total fertilizer-applied area compared to the conventional area. These results indicate that seedling quality, flowering date of the first flower of the apical flower cluster, and yield after planting are equivalent to those of the conventional method in late September when "Amao" seedlings are grown by the total fertilizer application method using coated fertilizer.

We estimated the cost of different fertilizer application methods during the seedling stage, taking into account the cost of materials and labor. As a result, the total cost per 10a was estimated to be 17,600 yen lower than that of the conventional method, because the total cost per 10a was reduced by the labor-saving fertilizer application, although the cost of materials increased with the introduction of the fertilizer applicator in the total fertilizer application area. In other words, in the total fertilizer application method, the increase in material costs was more than offset by the decrease in labor costs due to labor-saving fertilizer application.

In conclusion, it is clear that the total application method of coated fertilizer using a metered-quantity fertilizer applicator for potted plants in raising strawberry "Amao" seedlings can produce seedling quality and yield comparable to those of conventional cultivation, and can save labor for fertilizer application.

References

●郡司掛則昭(2020)

鉢もの花き栽培における緩効性肥料による省力施肥.

農業と科学 726:9-11

●本田藤雄(1977)

生理・生態からみたイチゴの栽培技術.

誠文堂新光社.東京.p136-140

●福岡県園芸振興推進会議(2006)

平成18年度版「あまおう栽培の手引き.3育苗管理.福岡県,p13-27

●福岡県農林水産部経営技術支援課(2020)

主要野菜の栽培技術指針(第11版).p17-22

●森下昌三(2014)

イチゴの基礎知識 生態と栽培技術.

誠文堂新光社.東京.p157-162

●泰松恒男・木村雅行(1981)

イチゴ宝交早生の促成栽培における苗質と開花,収穫パターンについて.

奈良県農試研報12:30-42

●竹内 隆・佐々木麻衣(2008)

イチゴ‘紅ほっぺ’の育苗方法が生育と収量に及ぼす影響.

静岡農試研報1:1-10

●植松徳雄(1998)

イチゴ栽培の理論と実際.

誠文堂新光社.東京.p40 -44

●吉田裕一・森本由香里・大井美知男(2002)

トレイ育苗したイチゴ品種の花芽分化に及ぼす気温と窒素栄養の影響.

園学雑71別2:372

No Soil - No. 24 Soil is a Product of the Environment

-風化と生物の作用が岩石から土をつくる

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

About 600 million years ago, 4 billion years after the birth of the earth 4.6 billion years ago, something like soil (early soil) was formed, and about 300 million years ago, the soil we imagine was formed on the earth. In the last issue, I told you the story of the formation of soil. This time, I would like to talk about how soil is created by the environment.

1. change in perception of soil

Until the 19th century, soil was considered to be nothing more than a soft, weathered rocky surface layer of the earth's crust. Dokuchaev (1846-1903), a young Russian geologist who later became known as the founder of soil science, changed this view to one in which soil is created by the environment.

He believed that soil is formed by the interaction of various factors such as rocks, which are the raw materials of soil, climate, plants and animals, and topography, and that the formed soil changes with time. He also argued that soil, like animals and plants, is one of the components of nature and that soil is a product of the environment. Let us look at this idea in detail below.

2. two factors that create soil - weathering and biological action

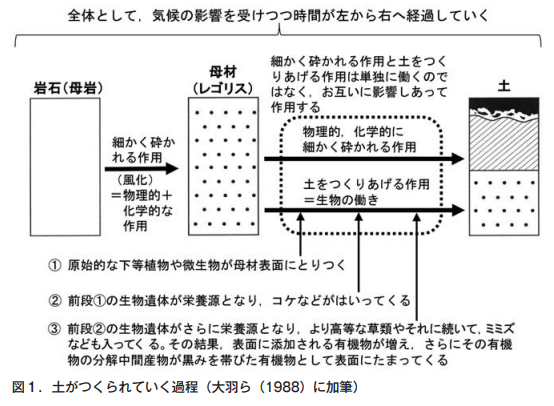

In Japan, soil made from volcanic ash (black soil) is widely distributed. However, from a global perspective, black soil is an exceptional soil, and the raw material for soil in general is rock. The rock used as the raw material is called the host rock. Soil is formed from the parent rock by two processes: the breaking of the rock into small pieces (weathering) and the formation of soil by the action of organisms on the broken rock (Fig. 1).

The first step in the formation of soil is for lichens and microorganisms, as described in last month's issue, to attach themselves to the surface of a material that has been broken into small pieces by weathering (this is called the parent material of soil). When they die after completing their lives, their remains are decomposed by other microorganisms. The decomposition products become plant nutrients. As these nutrients accumulate, an environment is created in which plants can live, and higher plants, such as mosses and grasses, invade. When mosses and grasses enter, their remains are decomposed by microorganisms and nutrients increase further. Then, soil animals (earthworms, etc.) can live there.

Soil animals live and die by feeding on the organic matter that has accumulated in the matrix as decomposition products of plant remains. As a result, the surface of the parent material becomes richer in nutrients. In this way, higher plants are able to live. As the higher plants die and are replaced by dead bodies, a black-colored layer of soil with a mixture of organic matter and the parent material gradually forms on the surface of the parent material.

The action that creates soil in this way is the result of the action of living organisms on the parent material. No matter how much a rock is weathered and crushed into small pieces, soil cannot be created without the presence and action of living organisms.

3. the function of soil-building organisms is affected by the environment

The workings of the organisms that make up the soil are closely linked to the environment. This is because the types of organisms and their activity are greatly influenced by the climate.

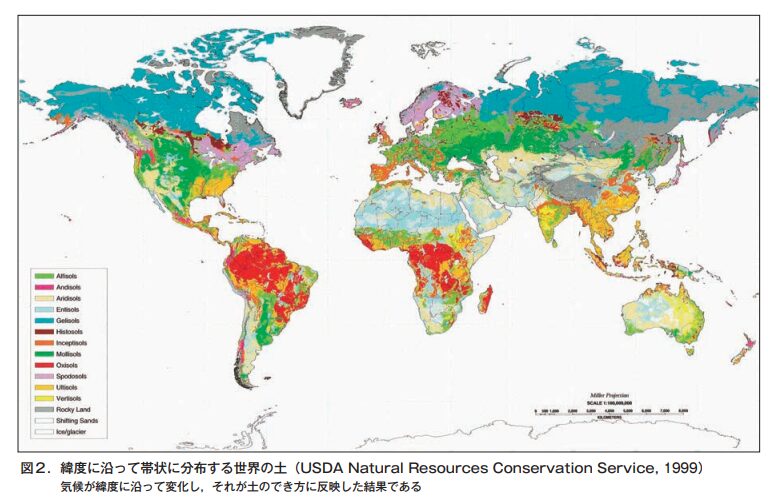

In cold regions at high latitudes, the amount of organic matter added to the soil is low because plant growth is poor. However, because of the cold weather, decomposition of organic matter by microorganisms does not progress, and organic matter accumulates, resulting in dark soil with a darker color, as indicated by the organic matter. On the other hand, in low-latitude tropical rainforest areas, the amount of organic matter added to the soil is much higher than in colder regions because of vigorous plant growth. However, because of the higher temperatures, the decomposition of organic matter by microorganisms is faster, and organic matter is less likely to accumulate in the soil. Therefore, the soil in this region does not darken, and a reddish-brown color is produced.

Soil is formed and changes within the limits of given environmental conditions, not at will. This is why Dochkiaev describes soil as "a product of the environment," and asserts that "soil is not some mechanical, accidental, lifeless mixture; on the contrary, it is a natural history formation (a historical natural body) determined and governed by independent and fixed laws. In other words, given certain environmental conditions, the same soil will be produced if the base material is the same. However, even if the base material is the same, if the environmental conditions are different, the resulting soil will be different. The environment creates the soil.

Looking at the world's soil again (Figure 2), it appears that soil is distributed in a band along the latitude of the earth.

This is because the climate varies greatly with latitude, and the soil is formed by the different actions of organisms in response to these changes.

From a macroscopic viewpoint, we can realize that "soil is a product of the environment," as Dokuchaev pointed out.

The moon is devoid of life. Therefore, the biological processes necessary to create soil do not work. Therefore, there are rocks on the moon, but no soil. Because the earth is at a perfect distance from the sun, the atmosphere and water can exist, and organisms were born. Thanks to the work of these organisms, soil was created and agriculture began.