Site Search

Search within product

No. 765 Published 2024(R6) .11

Click here for PDF version

農業と科学 令和6年11月

本号の内容

§タケノコ栽培の「働き方改革」

-緩効性肥料による施肥作業の省力化-

Fukuoka Prefectural Agriculture and Forestry Experiment Station

資源活用研究センター

森 康浩

茶木 彩佳

谷崎 ゆふ

(現 福岡県筑後農林事務所)

井手 治

(現 福岡県農林業総合試験場 筑後分場)

§土のはなし-第36回

先進国経済が途上国の土や資源を収奪する

-その現実と環境破壊の事例から学ぶこと

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

Bamboo shoot cultivation "work style reform

-緩効性肥料による施肥作業の省力化-

Fukuoka Prefectural Agriculture and Forestry Experiment Station

資源活用研究センター

森 康浩

茶木 彩佳

谷崎 ゆふ

(現 福岡県筑後農林事務所)

井手 治

(現 福岡県農林業総合試験場 筑後分場)

Introduction

It can be served with cooked rice, simmered dishes, tempura, and stir-fried dishes. Bamboo shoots' chewy texture and deep flavor make Japanese people feel the arrival of spring. Fukuoka Prefecture has been the largest producer of bamboo shoots in Japan for 15 years since 2010 (Forestry Agency, 2024). However, even in the main production area, production has been declining year by year. As with other commodities, this is thought to be due in part to the decrease and aging of producers (Katanoda, 2008; Sun et al., 2021). Therefore, in order to maintain the production area, labor-saving work is strongly required. The most labor-intensive tasks are harvesting and bamboo cutting (Sun et al., 2021), and fertilization to compensate for the annual deprivation of nutrients is recommended to be done multiple times (Nonaka, 2003), so there is room for labor saving. However, in our study, we found that the difference in the abundance and yield of bamboo shoots was greater in bamboo groves with less nitrogen fertilization (Tanizaki et al., 2024), and there is a risk that income may become unstable if the number of fertilizer applications is easily reduced. On the other hand, if the amount of fertilizer applied per application is increased and the number of applications is reduced, it will be difficult to supply the right amount of nutrients at the right time according to the growth stage of the bamboo shoots.

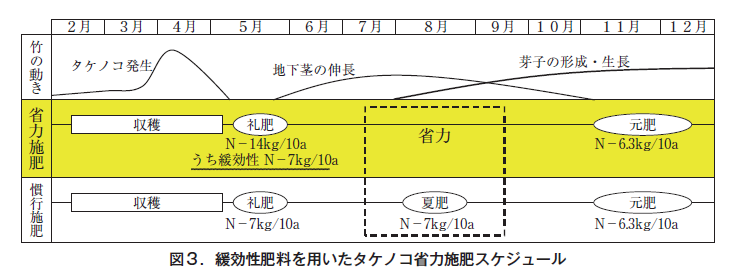

そこで本報では,窒素成分を徐々に溶出させる緩効性肥料を用いることで施用回数を減らし,施肥作業の省力化を検討した。具体的には,礼肥用の速効性肥料と夏肥用の緩効性肥料を混合したものを春季の礼肥時に一括施用することで夏肥(図1)を省くというものである。本報では,タケノコ収量や作業時間を調査するとともに,土壌窒素量の推移も追跡し,省力効果を検証した。

2. Methods

(1) Outline of the test site

The test site was a bamboo grove plot (60 m elevation, north-facing slope) at the Fukuoka Prefectural Agricultural and Forestry Experiment Station, Research Center for Utilization of Resources, located in Yamamoto-cho, Kurume City, Fukuoka Prefecture. The plot was planted in 1995, and has been managed by cutting down bamboos and tailoring parent bamboos to achieve a density of 300 standing bamboos/10a every year. The soil is a fine-grained normal brown forest soil.

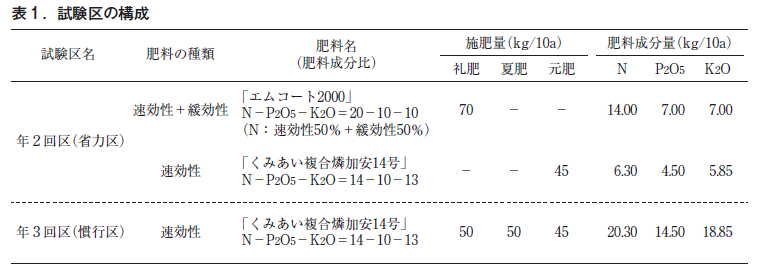

試験区は,夏肥を省略して礼肥・元肥を行う年2回区(以下,省力区)と礼肥・元肥の間に夏肥を加えた年3回区(以下,慣行区)の2つとした。試験区間で地利条件が同じになるよう,等高線沿いに25㎡の方形区を4反復ずつ設定した。

(2) Fertilization conditions

Two types of fertilizers were used: "Emcote 2000" (manufactured by J-Cam Agri Co., Ltd. under the registered name "Emcote 2000D-50 Special for Kumiai Rice"), a 50% mixture of a fast-acting fertilizer and a slow-acting fertilizer coated with granular urea, and "Kumiai Compound Phosphorus Additive No. 14" (manufactured by J-Cam Agri Co., Ltd. under the pet. (manufactured by J-Cam Agri Co., Ltd., pet. name: "Phosphorus additive No. 14 for bamboo shoots") were used.

In the labor-saving area, 70 kg/10 a year of M-Coat 2000 was applied as a courtesy fertilizer, and 45 kg/10 a year of Kumiai Combined Phosphorus Additive No. 14 was applied as a primary fertilizer. In the conventional treatment, "Kumiai Combined Phosphorus Additive No. 14" was applied three times a year: 50 kg/10a as a courtesy fertilizer, 50 kg/10a as a summer fertilizer, and 45 kg/10a as a primary fertilizer. The amount of nitrogen applied per year was the same in both compartments (Table 1).

Fertilizer application dates for the labor-saving plots were May 27 (courtesy fertilizer) and November 27 (original fertilizer) in 2019, May 26 (courtesy fertilizer) and November 24 (original fertilizer) in 2020, and May 19 (courtesy fertilizer) and November 30 (original fertilizer) in 2021. In the conventional plot, the courtesy fertilizer and the first fertilizer were applied on the same days as in the labor-saving plot, and the summer fertilizer was applied on August 26, 2019, August 24, 2020, and August 25, 2021.

(3) Survey Method

A. Yield yield

Every few days from February 5 to May 12 in 2020, February 12 to May 10 in 2021, and February 3 to May 12 in 2022

The researchers visited the test sites on the first day of the study and dug up the bamboo shoots with a hand hoe. Each time, all the mushrooms were dug up while carefully inspecting both test sites to ensure that there were no leftover mushrooms. Bamboo shoots were placed in fertilizer bags to prevent them from drying out, and immediately brought back to the Resource Utilization Research Center of the Fukuoka Prefectural Agricultural and Forestry Research Institute, which is located near the test site, to record the weight and number of individual peeled shoots.

A. The work shall be performed in accordance with the following schedule. Working hours

両試験区の礼肥および夏肥の施肥作業について,肥料袋の現場搬入から肥料散布完了までの所要時間(100㎡あたり)をストップウォッチで計測し,10a・1人あたりの作業時間に換算した。

C. Nitrogen content of the soil Nitrogen content of soil

To compare the changes in nitrogen content in the soil after fertilization in the two test plots, we applied a courtesy fertilizer on May 19, 2022 and a summer fertilizer on August 18, 2022, and collected soil samples periodically from May 18, the day before the courtesy fertilizer, to September 28, 2022. Each time, soil samples (0.5 to 5 cm deep from the soil surface, excluding fallen leaves) were collected from five locations per square plot using a core sampler and thoroughly mixed. Soil analysis was conducted using a slightly modified version of the Soil Standard Analysis and Assay Methods Committee (1986). To 24 g of the collected soil, 120 mL of 10% potassium chloride solution was added and shaken for 30 minutes. Twenty mL of the filtrate was filtered through nitrate-free filter paper and semi-microdistilled. In addition, 0.2 g of magnesium oxide and 0.2 g of DeValta alloy powder were added to the same distillation apparatus. After the distillation, inorganic nitrogen content (ammonia nitrogen + nitrate nitrogen) per 100 g of dry soil was determined by titrating with 1/50 sulfuric acid solution and finding the difference with 20 mL of blank (10% potassium chloride solution) and applying the following formula. The measurement was repeated three times per test plot (three square sections).

Inorganic nitrogen content = 0.2801 x f x (T-B) x

Volume of water extracted / Volume of distilled liquid x

100 / Sample dry weight

f: Correction coefficient for 1/50 prescribed sulfuric acid solution

T: Sample titration value

B: Blank titration value

3. results

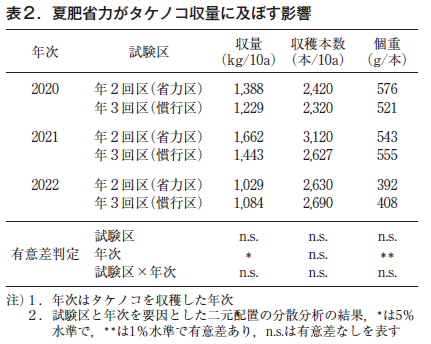

(1) Yield

Table 2 shows the yield, number of pieces harvested, and weight of bamboo shoots harvested from 2020 to 2022, and although there were significant differences in yield and weight among years for the three years, there were no significant differences among test plots for any of the years. The interaction between the test area and year was also not significant. When yields were broken down by month, yields were highest in April, especially in 2022, when more than 90% of the total crop was harvested in April, but monthly yields were similar with no significant differences among the test plots (data omitted).

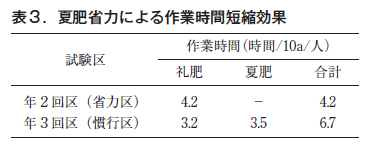

(2) Working hours

Table 3 shows the working hours required for fertilizer application. The labor-saving area applied 1.4 times as much fertilizer as the conventional area, and thus required 4.2 hours/10a/person, 1.3 times as long as the latter area. Although the amount of summer fertilizer applied in the conventional area was the same as that of the courtesy fertilizer, the summer fertilizer required 3.5 hours/10a/person, 1.1 times longer than the courtesy fertilizer, probably because the work efficiency was reduced due to the heat. Assuming that the labor-saving zone required 2.5 hours per 10a/man per year less than the conventional zone, assuming that the labor for the application of the original fertilizer was the same in both test zones.

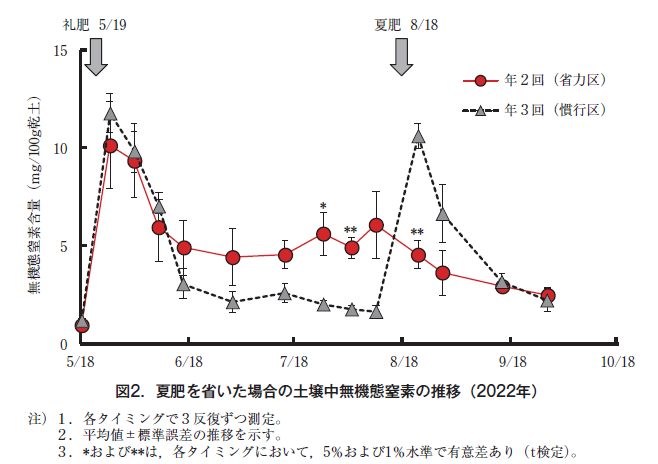

(3) Inorganic nitrogen in soil

Figure 2 shows the changes in the amount of inorganic nitrogen in the soil of both test plots. The amount of soil nitrogen was about 1.0 mg/100 g in both test plots before fertilization. On May 26, 2022, one week after fertilization, the amount of nitrogen in both test plots rose sharply to 10.1 mg/100 g in the labor-saving plot and 11.8 mg/100 g in the conventional plot. Concentration peaked on May 26, 2022, and then decreased, but in the conventional area, it decreased sharply to 3.0 mg/100 g on June 16, one month after fertilization, and continued to decrease until August 10, 2022, when it reached 1.6 mg/100 g.

On the other hand, in the labor-saving area, the decrease eased on June 16 and remained at about 5 mg/100 g until August 10, just before summer fertilization. Then, the nitrogen level in the conventional area increased sharply to 10.6 mg/100 g on August 22, the same level as the peak immediately after the summer fertilizer was applied on August 18. As a result, the nitrogen concentration in the conventional plot significantly exceeded that in the labor-saving plot, but after September 15, one month after the summer fertilization, the nitrogen concentration in both test plots remained almost the same.

Consideration

The fertilization schedule for bamboo shoot production is based on the customary zone in this study (Figure 3; Nonaka, 2003).

In other words, in May, the parent bamboo is fertilized with a "courtesy fertilizer" to replenish nutrients deprived by digging bamboo shoots to restore vigor and promote the growth of underground stems, in August with a summer fertilizer to promote the formation of shoots, the original form of bamboo shoots, and in November with a former fertilizer to enlarge the shoots and promote their growth into bamboo shoots. Four components of fertilizer are said to be important: nitrogen, phosphoric acid, potassium, and silicic acid (Ueda, 1963). In support of this, we recently found that the higher the amount of nitrogen fertilizer applied and the higher the nitrogen content of the soil, the smaller the difference in the abundance and yield of bamboo shoots (Tanizaki et al., 2024). In addition, a recent genetic comparison of the metabolism of Mohn's bamboo shoots with and without nitrogen fertilization has revealed a mechanism whereby nitrogen fertilization promotes nitrogen metabolism and amino acid biosynthesis in the early stages, resulting in enhanced bamboo shoot growth (Yang et al., 2022).

As mentioned above, the timing of fertilizer application, especially nitrogen, during the growth stage is very important in bamboo shoot production. In this study, we measured the amount of inorganic nitrogen in the soil (Figure 2), not during the bamboo shoot yield survey, but after May 2022, when the survey was completed. Therefore, we cannot directly confirm whether the amount of nitrogen during the yield survey period from 2020 to 2022 also changed as shown in Figure 2. However, assuming that the nitrogen content was similar, the nitrogen content in the labor-saving zone was clearly low only for a limited period, from immediately after summer fertilization to about 10 days later, suggesting that the slow-release property of the slow-release fertilizer was effective and the yield of the labor-saving zone was equivalent to that of the conventional zone.

To our knowledge, no other studies have examined the effect of slow-release fertilizers on bamboo shoot yield, and neither Katanoda (2008) nor Ueshikuryo (2010), who examined changes in soil nitrogen content in bamboo shoot production forests using different slow-release fertilizers at different times, have examined the relationship with yield. Furthermore, it is difficult to observe the growth of subterranean stems and shoots, and the situation after the application of slow-release fertilizers has not been confirmed.

Although there are some unverified aspects, the yield of bamboo shoots in this study exceeded the yield target of 1000 kg/10a (Nonaka, 2003) corresponding to an annual nitrogen fertilizer application rate of 20 kg/10a every year for three years, and the coefficient of variation of yield was 0.23 (labor-saving area) and 0.14 (conventional area), which was sufficiently low compared to the average of 0.38 in 87 areas in Fukuoka Prefecture, which was investigated by Tanizaki et al. (2024), and the coefficient of variation of yield was 0.23 (labor-saving area) and 0.14 (conventional area), which was sufficiently low compared to the average of 0.38 in 87 areas in Fukuoka Prefecture, suggesting that the twice-yearly labor-saving fertilization schedule did not have a negative impact on bamboo shoot production.

On the other hand, how much did the labor-saving fertilizer application schedule reduce working hours? Compared to the conventional schedule, the labor-saving area required 2.5 hours less work per 10a/person per year (Table 3). In the conventional area, weeding is required before summer fertilization (Fig. 4), but if weeding can also be labor-saving, the effect of shortening the work time will increase to 7 hours/10a/person (data omitted). Although it is difficult to completely eliminate weeding work (Sun et al., 2021), which is done several times a year, it is advantageous to avoid the height of summer before summer fertilization, when labor-saving fertilization schedules reduce work efficiency. Since many bamboo shoot growers have multiple operations combining other crops, the reduction of summer work allows them to diversify their operations by allowing them to work on other crops. Furthermore, although the unit price of M-Coat 2000 is slightly higher than that of conventional fertilizers, the annual fertilizer cost is estimated to be lower than that of conventional fertilizers (for prices and handling information, please contact your local JA). Thus, the fertilizer application schedule described in this report, which enables labor saving and decentralization, is expected to contribute to "work style reform" in bamboo shoot production.

Currently, in bamboo shoot production, smart agriculture is progressing with the development of a "bamboo shoot digging assistant robot" (Horiuchi et al., 2015), which is shaped like a brushcutter and has a rotating mulberry blade at its tip, and a detector that uses resonance-type electrodes to detect underground bamboo shoots (Iwamoto et al., 2022). While looking forward to the development of such technologies, we would like to promote "work style reforms" that can be done now, and support production areas so that they can be maintained.

5. cited references

●壌標準分析・測定法委員会編(1986)

土壌標準 分析・測定法,354pp,博友社,東京

●堀内俊二・堀 貴裕・阿部大樹(2015)

タケノコ掘り補助ロボットのデザイン.

九州産業大学工学部「ロボメカ・デザインコンペ2015」

●岩本孝太・坂本雅弥・岩城昴琉・黒木太司(2022)

共振型電極を用いた簡易土中タケノコ探知機の基礎的検討.

電子情報通信学会論文誌 2022/3 Vol. J105‒C No.3:81-86

●上敷領芳広(2010)

新配合の緩効性タケノコ専用肥料の適性とモウソウチク林における施肥量算出システム

九州森林研究63:143-145

●片野田逸朗(2008)

タケノコ栽培における肥培管理の改善-被膜肥料の選定と施肥基準の再検討-

鹿児島県森技総セ研報11:1-15

●Kebin Yang, Chenglei Zhu, Junbo Zhang, Ziyang

Li, Yan Liu, Xinzhang Song, Zhimin Gao(2022)

Nitrogen fertilization in bamboo forest accelerates the shoot growth

and alters the lignification process in shoots.

Industrial Crops and Products 187, Part A, 115368

●野中重之(2003)

タケノコ生産管理技術と新たな竹林経営

福岡県森林林業技術センター研究報告4 : 1‒52

●林野庁(2024)

用林産物生産統計調査 確報 令和5年特用林産基礎資料

●孫 鵬程・貫名 涼・柴田昌三(2021)

鹿児島県の管理モウソウチク林における管理・生産状況および林分構造の現状

日本森林学会誌103:96-104

●谷崎ゆふ・黒栁直彦・井手 治・友清昇太・森 康浩(2024)

福岡県のタケノコ生産における豊凶差の拡大要因.九州森林研究 77 :135-140

●上田弘一郎(1963)

有用竹と筍-栽培の新技術-.pp141-142,博友社,東京

No Soil - No. 36

先進国経済が途上国の土や資源を収奪する

-その現実と環境破壊の事例から学ぶこと

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

In the past five articles, I have described the current state of the world's soil degradation and the crisis it is endangering. The main cause of soil degradation has been inappropriate human activities on agricultural lands. However, there is a deeper root cause hidden in the soil degradation caused by inappropriate human activities. The hidden cause is the economic structure in which the globalization of developed countries' economies deprives emerging and developing countries of labor and resources. Saito (2020) called such affected areas and inhabitants the Global South.

In this issue, I will present examples of economic exploitation by developed countries that have caused soil degradation and environmental destruction in the Global South. In each case, the environmental destruction was caused by the expropriation of labor and resources in the name of producing raw materials necessary for our daily lives.

Example of oil palm plantation in Indonesia

The oil palm, also called palm palm, produces palm oil from the pulp of the fruit and palm kernel oil from the seeds. The two are different products with different main components (Figure 1).

Palm oil is not only inexpensive, but is also resistant to oxidation. For this reason, it is widely used in processed foods, snacks, fast foods, French fries, ice cream, chocolate, margarine, soap, detergents, cosmetics, and other products. However, in Japan, the labeling of food ingredients only mentions "vegetable fats and oils. Therefore, it is difficult to be aware of the fact that we depend heavily on palm oil in our daily lives.

The cultivation area of oil palm, the raw material of palm oil, has doubled in the 21st century. In Indonesia, the largest palm oil-producing country, the oil palm cultivation area was only 70,000 ha in 1961. By 2018, it was 6.78 million hectares, a rapid increase of about 100 times. The expansion of cultivation area was supported by the overexploitation of tropical rainforests. Overexploitation has led to rapid deforestation. Not only that, the rapid increase in palm oil production had a destructive impact on the livelihood of the local people, who had depended on the natural environment for their livelihood.

After clearing the rainforest, the traditional techniques of local small-scale farmers were not adopted in the creation of oil palm plantations, plantation management, and harvesting methods. The national government initiated a "production technology guide" based on the oil palm certification system. It was a "guide" aimed at meeting the increasing demand for vegetable oils and fats in the world and increasing the international competitiveness of the palm oil industry. In other words, the plantations were to be monocultures of oil palm, with intensive plantation techniques that required large inputs of labor and materials (chemical fertilizers and pesticides) (Terauchi, 2021).

However, few small-scale farmers were able to adapt to this technology, and in practice, intensive cultivation was carried out very inappropriately. As a result, the soil on the farms suffered from erosion, and the overused chemical fertilizers and pesticides flowed into the rivers, reducing the number of river fish. The river fish were a valuable source of protein for the local population. The residents were no longer able to consume that protein source and had to spend more money to obtain another source of protein. To make ends meet, they turned to illegal trade in wildlife, especially endangered species such as orangutans and tigers. Thus, the lives of the inhabitants have changed drastically (Saito, 2020).

This tragedy is occurring in the shadow of our demand for cheap palm oil production.

2. deforestation for papermaking raw materials, examples in the manufacturing process of avocado, soybeans, cacao, etc.

In Indonesia, where the palm oil example was introduced, the country's largest paper manufacturer sought raw materials from tropical rainforests and peat forests on the islands of Sumatra and Kalimantan in order to export paper to more than 120 countries, including Japan. The manufacturer was supposed to implement "Free, Prior and Informed Consent (FPIC)" with the local people. However, this was only in name, and deforestation for raw material procurement was carried out on the grounds that FPIC was implemented, resulting in conflicts with local residents (Sagara, 2021). In Japan, FPIC-certified copy paper is also sold. They appear to be environmentally friendly paper. However, there are local residents who are suffering from the effects of deforestation.

In the development of avocado plantations in Latin America, in addition to illegal deforestation to expand production, water is overconsumed to meet the particular water requirements of avocados, resulting in local water shortages (Rokuji, 2021).

In Brazil, a major exporter of soybeans important to our diet, the president has tacitly approved the overexploitation of the rainforest, which has displaced indigenous peoples from the lands where they lived (Chandrasekhar, 2020). In coffee plantations and cacao factories, children (aged 5-17) work for low wages to provide for themselves and their families in order to produce the raw materials for the delicious coffee and chocolate we enjoy (Figure 2). The number of children working in the agriculture, forestry, and fisheries industries is estimated to be 112.1 million worldwide, or about 70% of the 160 million children working worldwide (Yoshioka, 2022).

3. case study in metal mining

アフリカのガボンでは金鉱山開発の名目で森林破壊が進み,それが人畜共通感染症の病原体を運ぶとされるコウモリなどの動物のすみかを破壊し,エボラ出血熱などの感染症まん延の原因を作り出している(斉藤,2020)。再生可能エネルギーとして注目される風力発電の原動機(タービン)や,化石燃料の消費抑制に期待されるハイブリッド車の電池などに利用されるレアアース(希少金属レアメタルの一種で希土類ともいう)も,その採掘にともなって環境破壊を進行させる。太陽光発電パネルにはレアメタルが利用され,同様の環境破壊が発生している。世界最大の生産国・中国では,レアアースの生産過程で排出される有毒ガスや,カドミウムなどの重金属類が不純物として排出され,環境破壊がひどい状況にある(Biggs,2011)。クリーンエネルギーを生産するために環境を破壊しているという皮肉な現実である。

4. the "cheap is good enough" mentality puts the burden of cost reduction on the weak.

Yamashita (2001) points out that, in response to consumers' demand for inexpensive food, "Just as each person has his or her own value, there is and must be a decent price for things. The cost reductions that make food inexpensive are achieved by externalizing the environmental impact of the cost reductions onto people and the natural environment somewhere far away.

We need to change our mindset not to use the spirit of the SDGs as a "pretty word" or an "alibi" for environmental concerns. We are called upon to change our consciousness, not to use the spirit of the SDGs as a "pretty word" or an "alibi" for our environmental concerns.