Site Search

Search within product

第767号 2025(R7).01発行

Click here for PDF version

§日本と世界の農業の発展に向けて

Jcam Agri Co.

代表取締役会長 藤野 恭弘

§排水不良復旧農地における肥効調節型肥料の植え溝施肥によるネギ生育改善効果

Crop Environment Department, Furukawa Agricultural Experiment Station, Miyagi Prefecture

瀧 典明

§北海道の露地ねぎにおけるハイパーCDUの低肥沃度土壌への活用

地方独立行政法人 北海道立総合研究機構

Planning and Coordination Department, Agricultural Research Division

Stationed at Hokkaido Nuclear Environmental Center

佐々木 亮

§土のはなし-第38回

有機農業の養分源・堆肥生産の課題

-堆肥生産には労力と土地が不可欠-

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

For the Development of Agriculture in Japan and the World

Jcam Agri Co.

代表取締役会長 藤野 恭弘

Happy New Year!

At the beginning of the year 2025, I would like to extend my greetings to all the readers of "Agriculture and Science".

Yes.

As of June 19 last year, I assumed the position of Chairman and Representative Director of JCAM Agri Co. I would like to further enhance my recognition of the management policy since its establishment, "to contribute to agriculture and related fields in Japan and around the world through fertilizers," and I will make every effort to live up to your trust and expectations.

Last year, many parts of Japan were hit by disasters such as the Noto Peninsula Earthquake and the torrential rains and strong winds caused by Typhoon No. 10. We express our deepest sympathies to those who have been affected by these disasters, and we pray for the earliest possible recovery.

From a global perspective, the price of fertilizer raw materials has remained high due to continued instability caused by political instability, such as the escalating conflicts in Ukraine and the Middle East. Import prices of urea, phosphorus ammonia, potassium chloride, etc., the main raw materials, have doubled since 2020, partly due to the weak yen. As a fertilizer supplier, we will continue our efforts to supply "better products at lower prices" and contribute to the stable supply of food both domestically and internationally through our specialty products such as coated fertilizers and slow-release fertilizers.

In Japan, a decrease in the area under cultivation due to the aging of agricultural producers and a decrease in the agricultural population are recognized as major social issues. Under these circumstances, the "Revised Basic Act on Food, Agriculture and Rural Areas" was enacted last year as a national policy. The revised law aims to "shift to an industry in harmony with the environment" and "maintain and develop agricultural production under a declining population.

Based on specific measures, we will work to strengthen food security and structural transformation of agriculture. As a company that has supported agricultural production in terms of fertilizers, we have high expectations for the future development of the policy.

There is no doubt that fostering agricultural leaders is an urgent issue, and we recognize that the promotion of smart agriculture and the shift to an industry in harmony with the environment, in particular, are extremely important factors for the future development of Japanese agriculture. As a fertilizer manufacturer, we will continue to promote research and development in cooperation with related parties to find out what kind of products and performance will be required in this trend toward smart agriculture.

From the viewpoint of fostering industry in harmony with the environment, corporate activities focusing on global environmental considerations have been attracting attention in recent years. We, too, have been strengthening our efforts to reduce the environmental impact of the problem of outflows of coated shells from the field. We have developed a new J-Coat with plastic content reduced to about 3%, and plan to promote the replacement of existing products throughout Japan. We have already developed and introduced to the market IBDU and CDU, which are synthetic slow-release nitrogen fertilizers without plastic coating. As for the development of environmentally friendly coated fertilizers, we are also focusing on the development of biodegradable resin-coated fertilizers and non-plastic coated fertilizers. We are determined to contribute to the future of agriculture by accelerating the development of products to reduce the environmental burden, which is expected to become increasingly important in the future.

Finally, I would like to conclude my New Year's greetings by asking for your continued patronage of this issue of "Agriculture and Science" and wishing you a happy and prosperous new year.

Fertilizer Regulation in Restored Farmland with Poor Drainage

植え溝施肥によるネギ生育改善効果

Crop Environment Department, Furukawa Agricultural Experiment Station, Miyagi Prefecture

瀧 典明

Introduction

In the field areas along the Sanriku coast of Miyagi Prefecture, the surface layer of the fields was almost completely lost due to the tsunami caused by the Great East Japan Earthquake and the subsequent debris disposal. In the areas where farmers were expected to be involved in agriculture, large plots of fields were created by haying, and the fields were also created with 30-cm-thick soil from the mountains. In this area, green onion had been one of the priority crops since just before the earthquake, so planting was promoted on the restored farmland in conjunction with the construction of machinery and facilities. However, the low soil fertility due to the lack of organic matter in the soil and the tendency of soil compaction to deteriorate hydraulic conductivity caused by soil compaction, which resulted in unstable leek growth due to poor drainage, were problematic.

On the other hand, in the cultivation of leeks, a one-shot base fertilizer containing a fertilizer with controlled fertilizer efficacy is sometimes used to save labor for fertilizer application, but these fertilizers are expected to have stable fertilizer efficacy even under poor conditions such as low fertilizer retention or excess soil moisture, and are therefore considered effective for stabilizing production in restored farmlands.

Therefore, this study examined a fertilization system that utilizes fertilizer with regulated fertilizer application in restored farmland with poor drainage.

2. Testing Method

(1) Outline of the test site

The field was located in a restored field in District T, Minamisanriku-cho, Miyagi Prefecture, Japan. The 30-cm surface layer of the field was a clayey clay layer, and the soil classification was "gravelly normal immature lowland soil (fine-grained brown forest soil fill development phase)." Leek planting in District T began in 2015, but because of wet damage, a 3% slope was constructed across the field as a surface drainage measure before cultivation began in 2017. As part of the construction work, 4 t/10a of cattle manure was applied as a soil preparation measure, but the soil organic matter content per 100 g of dry soil before the start of the 2017 test was 1.2 g and 0.2 mg of soluble nitrogen, far below the improvement targets (organic matter content of 3 g or more and soluble nitrogen of 5 mg or more) in the basic guidelines for soil fertility enhancement. The soil fertility was extremely low.

(2) Fertilization design

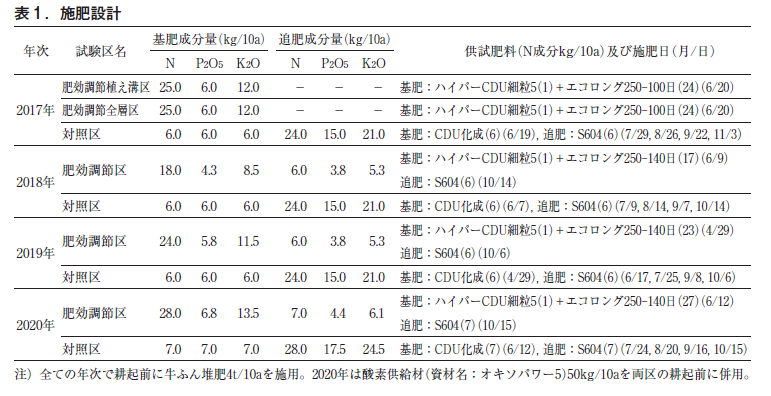

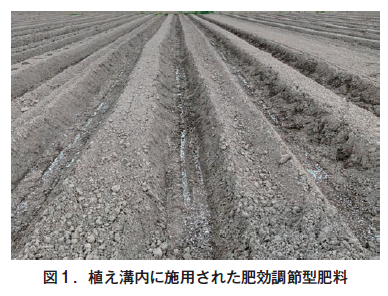

In 2017, when the trial was initiated, a control plot was established in which base fertilizer was applied in a full layer and four additional applications of fertilizer were made before soil application, whereas a plot was established in which fertilizer with regulated fertilizer was applied in the planting furrows as a total base fertilizer (Table 1, Figure 1). A low PK Ecolong 250-100 day type fertilizer (20-5-10) was used, assuming that phosphorus and potassium were supplied by compost, combined with a seedling box application of Hyper CDU fine grain 5 (Nishihata, 2011) to compensate for the fertilizer effect immediately after planting. The amount of fertilizer applied was set at 83% of the control, because it is said that the amount of fertilizer applied in the planting furrows can be reduced by 20% compared to conventional fertilizer application (Konno et al., 1998). In addition, a plot was established in which a full layer of fertilizer with controlled fertilizer was applied as a comparison. In 2019, the total amount of fertilizer applied in the fertilizer-regulated area was the same as in the control area. In 2020, the total amount of fertilizer applied in both test plots was increased by an additional 5 kg/10 a. In addition, an oxygenator was used.

(3) Outline of cultivated species

The leek variety "Summer Fan Power" was used in all years, with 3-seedings of chainpot LP303 in 2017, 2019, and 2020, and 2-seedings of the same CP303 only in 2018, and the row spacing at planting was 90 cm. Planting and yield survey dates were June 20 and December 7, 2017, June 8 and December 7, 2018, April 29 and December 23, 2019, and June 12 and December 1, 2020, respectively. Pest and weed control were farmer practices. In all four years, the trials were conducted in separate fields in District T. The previous crop in all fields was leeks.

(4) Fertilizer nitrogen leaching process

In order to understand the leaching process of the fertilizer under field conditions, mesh bags containing 3 g of ECOLONG 250 were buried in the soil in the field. The bags were collected over time during the growing period of leeks and the amount of residual nitrogen was measured, and the percentage of nitrogen that decreased was used as the leaching rate.

Test Results and Discussion

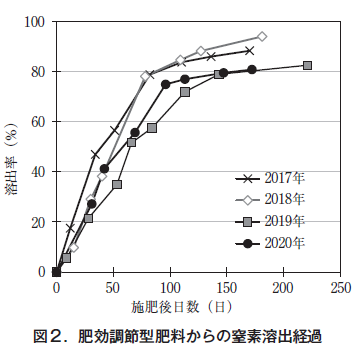

The nitrogen leaching from the test fertilizers measured by the field burial method showed that in 2017, when the 100-day type was used, the leaching rate exceeded 80% on October 8, 110 days after fertilizer application, and thereafter almost no fertilizer effect was observed for 2 months until harvest (Figure 2). Therefore, from 2018 onward, the 140-day type was used and the system was changed to one additional application of fertilizer. As a result, in 2018, when May-July tended to be hot, leaching was almost the same as in 2017, but in 2019 and 2020, leaching tended to persist until later in the season than in 2017.

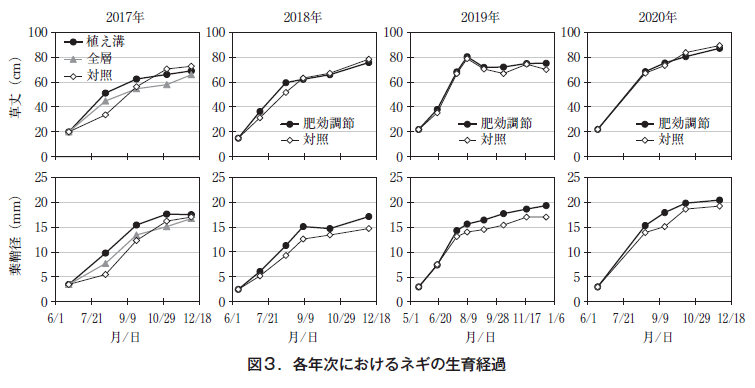

Looking at the growth progress of leeks, in 2017, both grass height and leaf sheath diameter remained higher in the fertilizer-regulated planting furrow area than in the control area, and at harvest, grass height in the control area was the highest, while leaf sheath diameter was higher in the fertilizer-regulated planting furrow area (Figure 3). On the other hand, the fertilizer-regulated full layer always remained below the planted furrowed area, and at harvest, both grass height and leaf sheath diameter were the lowest among the three areas.

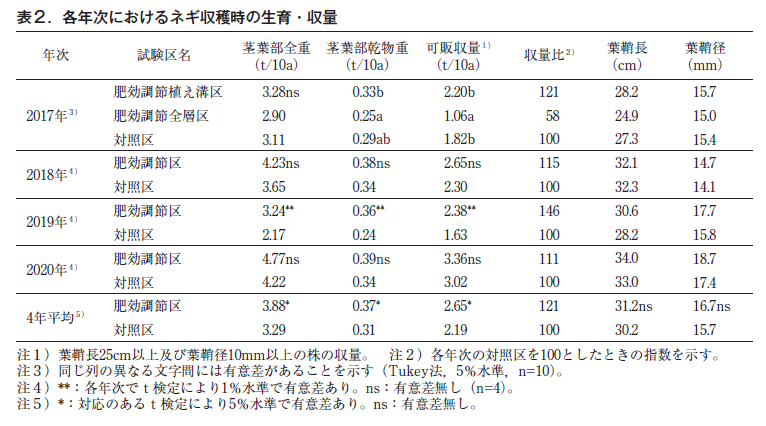

In terms of growth and yield at harvest, the fertilizer regulated planting furrow area tended to outperform the control area in terms of stover weight and yield, but the differences were not statistically significant (Table 2).

On the other hand, the yield in the full-layer fertilizer-regulated zone was significantly lower than that in the other two zones. Kobayashi (1994) found that full-layer and row applications of fertilizer with regulated fertilizer produced similar yields in leeks grown with full basal fertilizer, but local application was considered more appropriate under poor drainage and low soil fertility conditions.

In 2018, the fertilizer design was changed to compensate for fertilizer efficacy in the second half of growth, resulting in higher grass height at harvest than the previous year (Figure 3) and higher yield trend than the control, but no significant differences were observed and the target yield of 3 t/10a was not reached (Table 2).

In 2019, when the amount of fertilizer applied in the fertilizer-controlled area was the same as in the control area and the planting time was accelerated, grass height in early August was the highest in four years, but growth was stagnant thereafter due to overgrowth of weeds caused by excessive soil compaction due to excessive moisture in the field during the rainy season (Figure 3). Even under such conditions, the leaf sheath diameter remained higher in the fertilizer-regulated area, and the stem and leaf weights and yield at harvest were also significantly higher in the fertilizer-regulated area (Table 2).

In 2020, the amount of fertilizer applied was increased to secure the target yield, and oxygen suppliers were used in combination, resulting in a yield of 3 t/10a in both the fertilizer-controlled and control areas, with a trend toward higher yields in the fertilizer-controlled area, although this was not statistically significant (Table 2).

Corresponding t-tests for the means of each item over the four years (values for the planting furrow area in 2017) showed that both stover weight and yield were significantly higher in the fertilizer adjustment area. Phosphorus and potassium concentrations in the stem and leaves at the time of green onion harvest did not differ between the two plots (data omitted), and no effect of lower PK fertilizer application in the fertilizer-controlled plot was observed.

Summary

In leek cultivation on restored farmland with poor drainage and low soil fertility, a planting trench fertilization system using a regulated-release fertilizer as the base fertilizer resulted in a 20% higher yield than the conventional fertilization system (base fertilizer + four additional fertilizer applications), suggesting that this fertilization method is more effective than conventional methods. This may be due to the fact that in poorly drained fields, root growth is easily restricted by excessive humidity, but the gradual supply of nitrogen from the fertilizer with regulated fertilizer at the base of the leek plant may have accelerated recovery from the humidity damage.

works cited

1)小林靖夫.1994.

緩効性窒素肥料を利用したねぎの全量基肥施肥栽培.

栃木県農業試験場研究成果集 13:37-38.

2)今野陽一,黒田潤,熊谷勝巳,富樫政博,上野正夫.1998.

ネギの全量基肥局所施肥における施肥効率.

東北農業研究 51:231-232.

3)西畑秀次.2011.

ネギの全量基肥栽培における初期生育向上のための育苗箱追肥技術.

農業と科学 632:1-3.

In open-air leeks in Hokkaido

ハイパーCDUの低肥沃度土壌への活用

地方独立行政法人 北海道立総合研究機構

Planning and Coordination Department, Agricultural Research Division

Stationed at Hokkaido Nuclear Environmental Center

佐々木 亮

Introduction

Because open-air leeks prefer well aerated soils, they are often grown in sandy soils with good drainage. However, the reality is that leeks grown on sandy soil are often heavily fertilized. In addition, despite the high fertilizer content, a relatively high proportion of M- and S-standard green onions are shipped, and some growers have difficulty in securing the weight of a single green onion.

Therefore, we focus on pre-planting seedling box fertilization using Hyper CDU and present our study on fertilization of open field spring-sown leeks in soils with low nitrogen fertility and cation exchange capacity (CEC), such as sandy soils.

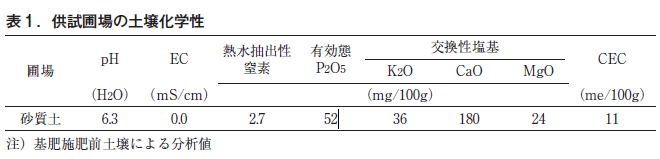

2. Testing Method

試験を行った圃場は北海道原子力環境センターの場内圃場で,熱水抽出性窒素が3mg/100g未満,CECが12me/100g未満の窒素肥沃度および陽イオン交換容量が低い砂質土である(表1)。露地ねぎの栽培は,栽植密度を条間1m×株間5cm×2粒/株の40粒/㎡とし,苗筒に日本甜菜製糖株式会社製チェーンポットCP303(264 株/冊)を利用した。苗箱施肥は特記がある区を除き,ハイパーCDU細粒2を利用し88g/冊を表面施用し,定植後換算で2kgN/10aとした。

Hyper CDU Fine Granules 2 is a slow-release nitrogen fertilizer with a nitrogen content of 30% and a fertilization period of 20 to 30 days for CDU (acetaldehyde condensed urea). CDU is a cyclized compound of two molecules of urea and two molecules of acetaldehyde, a fertilizer component mainly degraded (mineralized) by microbial degradation.

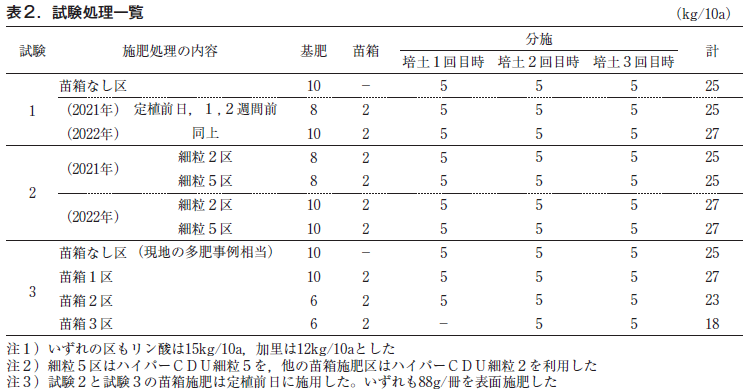

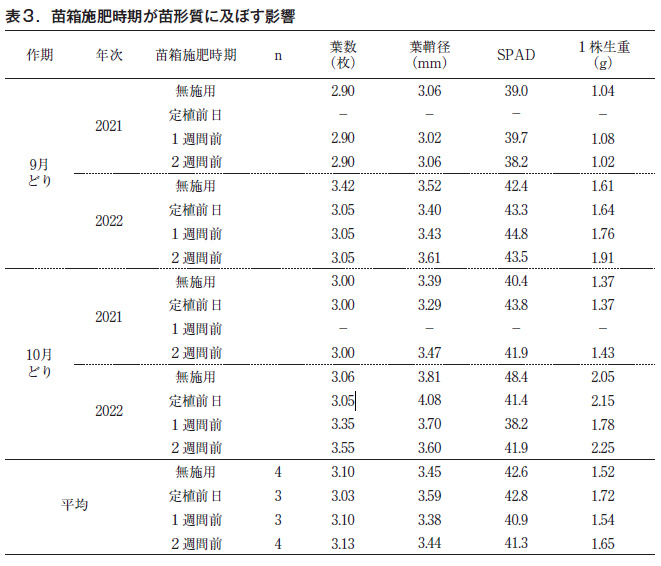

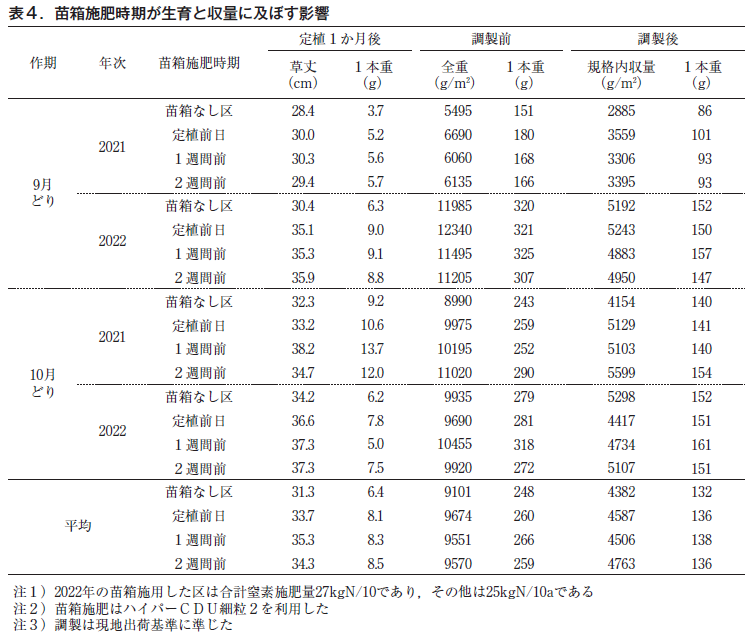

Test 1 was conducted in two cropping seasons in 2021-2022 with four levels of seedling box fertilizer application timing: no fertilizer, one day before planting, one week before planting, and two weeks before planting.

Test 2 was a comparison of Hyper CDU fine granules 2 and Hyper CDU fine granules 5 (fertilization period of 30-60 days) as a seedling box fertilization material comparison test. Seedling box fertilizer was applied one day before planting.

Trial 3 was a nitrogen fertilization trial, in which the treatments in Table 2 were applied in two cropping seasons in 2022-2023.

Results and Discussion

(1) Study of seedling box fertilizer application timing (Test 1)

We investigated whether seedling box application of fertilizer to open field leeks would cause problems such as fertilizer burn on seedlings, and when the best time to apply fertilizer would be. Under the conditions using Hyper CDU fine granule 2, which has a relatively fast leaching rate, seedling characteristics did not differ from those of seedlings without a seedling box and no fertilizer burn was observed when the box fertilizer was applied from two weeks before planting to the day before planting (Table 3). In addition, the applied fertilizer remained adhered to the surface of the seedling box and did not dissipate even after planting, and was applied at the base of the plant after planting. Growth and yield after planting tended to be higher in the area where fertilizer was applied to the seedling boxes than in the area where fertilizer was applied without the boxes (Table 4). There was no difference in the timing of fertilizer application.

As shown above, seedling box fertilization using Hyper CDU fine granules 2 did not cause any problems with seedling quality and had the same effect on growth and yield after planting if the application time was within the range from two weeks before to one day before planting.

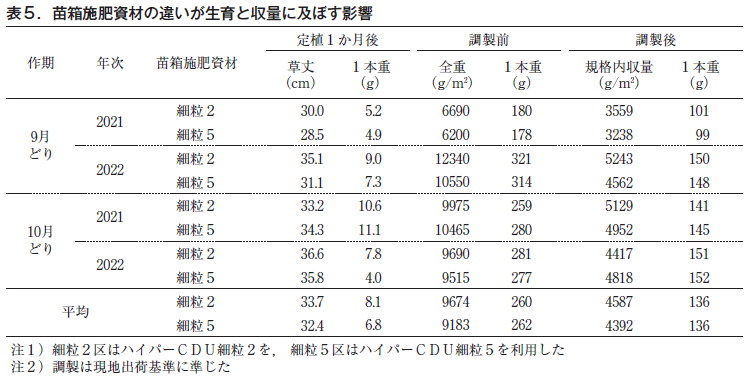

(2) Selection of seedling box fertilizer materials (Test 2)

The effects of Hyper CDU fine grain 2 and Hyper CDU fine grain 5, which differ in nitrogen fertilization period, on seedling box fertilization of leeks in the open field were compared. Although there was no significant difference in plant height and one plant weight one month after planting, the fine CDU 2 tended to outperform the fine CDU 5 (Table 5). No problems were observed in the subsequent growth, and there was no discernible difference in the in-specification yield and weight per plant after preparation between the materials.

From the viewpoint of promoting early growth, Hyper CDU fine granule 2 was considered suitable as a seedling box fertilizer material because of its rapid elution.

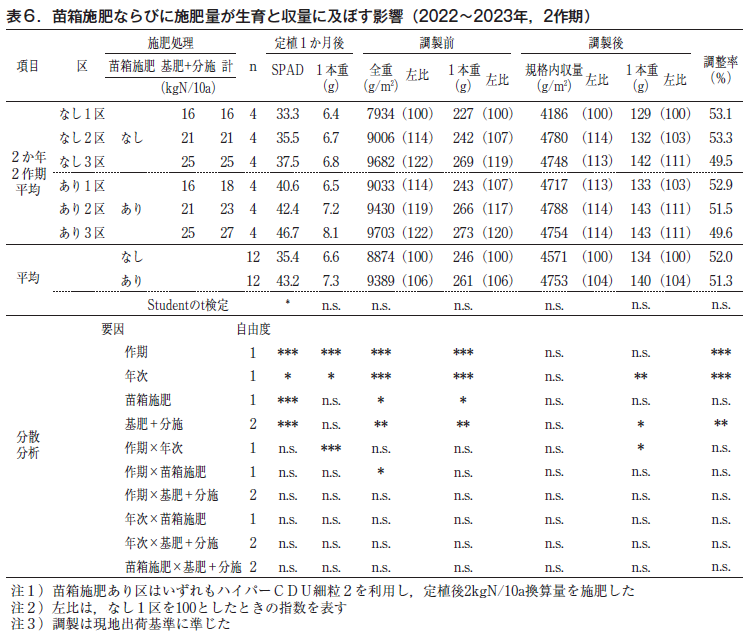

(3) Examination of nitrogen fertilizer amount (Test 3)

Nitrogen fertilizer application rates were examined for a combination of seedling box fertilization, basal fertilization, and partial fertilization. First, SPAD values at 1 month after planting were higher in the group with box fertilization than in the group without box fertilization (Table 6). The higher the amount of nitrogen fertilizer applied, the higher the SPAD value. In this case, the SPAD value was higher in the "with 1" group than in the "without 2" group, where the amount of nitrogen fertilizer applied was higher. The same relationship was observed in the "Yes 2" and "No 3" areas. The application of seedling box fertilizer was considered to have a greater effect on the initial growth of the seedlings than the increase in the amount of base and partial fertilizers.

In terms of total weight before preparation and single seedling weight, the group with seedling box fertilization was heavier than the group without seedling box fertilization, and the higher the nitrogen fertilization level, the heavier the seedlings tended to be.

The post-preparation within-specification yields tended to be heavier in the group with seedling box fertilization than in the group without seedling box fertilization, but the nitrogen fertilization level was at a plateau with no discernible effect, except in the "no fertilization 1" area. Thus, the effect of nitrogen fertilizer level on pre-conditioning total weight and in-specification yield tended to be slightly different. In addition, the high nitrogen fertilizer application tended to cause more deformed plants (dwarfed plants) in the high nitrogen fertilizer application area.

To examine the appropriate amount of nitrogen fertilizer, we first focused on the "None 1" area. Its growth rate was remarkably small, and it appeared to be deficient in nitrogen nutrients. The amount of nitrogen fertilizer applied was set according to the standard amount in Hokkaido (18 kg N/10a of nitrogen fertilizer for soils with low nitrogen fertility in the Hokkaido Fertilizer Guide). However, it is necessary to study the amount of nitrogen fertilizer applied to soils with low nitrogen fertility and cation exchange capacity, such as sandy soil, as in the test conditions.

According to the results of the interview survey, the amount of nitrogen fertilizer applied to leeks in the open field is often higher than 25 kg N/10a. Although the yield and weight per plant of "Pear 3", which corresponds to this high fertilizer application, were higher than those of "Pear 1", the preparation rate was lower, and there were concerns about a decrease in production efficiency and an increase in labor for preparation and residue treatment.

Therefore, we examined whether it was possible to improve the preparation rate and ensure both in-specification yield and one-plant weight. The results shown in Table 3 for each plot indicate that the "Yes 2" plot had almost the same within-specification yield and one-plant weight as the "No 3" plot, which had a higher nitrogen fertilizer rate, and tended to have better growth and preparation rate one month after planting. The "Yes 1" area also had almost the same within-specification yield and one-plant weight as the "No 2" area, which had a higher nitrogen fertilizer application level.

These results suggest that the combined application method with seedling box fertilization has the characteristics of better initial growth and higher fertilization efficiency than the conventional method of applying only base fertilizer and partial fertilization, thus ensuring good initial growth and in-specification yield even with reduced nitrogen fertilization, and increasing the preparation rate through reduced nitrogen fertilization.

(4) Study of workability and cost of seedling box fertilization

苗箱施肥は育苗床に設置したままのチェーンポット苗に対し,ハイパーCDU細粒2を定植前日までに施用する。施肥作業は育苗箱粒剤散布器や動噴など既存の機材が使用でき,専用の農機具を必要としない。施肥量は,264株/冊の苗筒を栽植密度20株/㎡で定植する場合,苗箱に88g/冊を施用すると,定植後に2kgN/10a換算となる。表面施用されたハイパーCDU細粒2は苗箱表面で固着し,そのまま定植されて株元施肥となる。この施肥量において,苗箱施肥によって生じる資材費は1840円/10aである。ただし,この資材費の増額は,減肥ならびに基肥が苗箱施肥分を調製して減ずる分の資材費減額によって相殺されることが見込める。このように,苗箱施肥は費用面の負担が軽微であると考えられた。

Summary

For open field spring-sown leeks in sandy soils with low nitrogen fertility and cation exchange capacity, a combination of pre-planting seedling box fertilization with a slow-release fertilizer (Hyper CDU) and a conventional fertilizer system of basal and partial application with chemical fertilizers was effective in ensuring early growth and yield while reducing fertilizer use.

No Soil - No. 38

有機農業の養分源・堆肥生産の課題

-堆肥生産には労力と土地が不可欠-

前 ジェイカムアグリ株式会社

北海道支店 技術顧問

松中 照夫

When crops are grown on farmland, nutrients from the farm soil are absorbed by the crops and taken out of the farmland when the crops are harvested. If the farmland is not replenished with the nutrients taken from the soil, the fertility of the soil will decline. Long before the advent of chemical fertilizers in the 19th century, compost was conceived as a nutrient-transfer material used to replenish the nutrients taken from farmland (for details, see the May 2022 issue of this series, Vol. 11).

In this article, we will consider the challenges of labor and land to produce and actively use compost as a nutrient transfer material, which is especially necessary in organic farming.

1. paddy rice cultivation does not require large amounts of compost due to the high natural supply of nutrients.

The widespread and general use of chemical fertilizers in the world is a relatively new story, having begun after World War II. Before that, compost was the main source of nutrients. However, the dependence on compost as a source of nutrients is small in rice cultivation and large in field cultivation. Let us first look at the rice crop to see why.

Rice paddies are flooded with water. At this time, nutrients such as nitrogen and potassium dissolved in the water are naturally supplied to the paddy field together with the water. At the same time, the paddy field under waterlogged conditions is in a reduced state of oxygen deficiency. Phosphorus and iron, which were originally difficult for plants to absorb in the soil, are converted to easily absorbable forms when they are reduced and made effective. The paddy field system has a large supply of nutrients from nature. Therefore, even if nutrients are not actively provided, the fertility of the soil does not decrease significantly. Therefore, rice paddies do not require a large source of nutrients to maintain soil fertility. This is the reason for the low dependence on compost as a source of nutrients. This may be one of the reasons why organic farming is more feasible in paddy rice cropping.

Therefore, the raw materials for producing compost as a source of nutrients were wild grasses and weeds growing outside of farmland, as well as leaves, branches, undergrowth, paddy field weeds, and straw, all of which could be collected through diligent human labor. In Japan, the use of livestock manure for compost production was not common, and livestock were mainly used as service animals.

2. crop rotation is a prerequisite for field cultivation, and composting using livestock is a source of nutrients.

Field crops cannot be grown in rows like rice paddies, and crop rotation is a prerequisite for field cultivation. Furthermore, fields do not have a natural supply system of plant nutrients as rice paddies do. Therefore, if the fields are not supplied with nutrients, crop yields will drop dramatically. Therefore, before the advent of chemical fertilizers, farmers relied heavily on compost as a source of nutrients. The idea of actively using livestock in field crop areas, especially in Europe, was then conceived. The final result was the four-year crop rotation of the Norfolk method, which was perfected in England in the 19th century.

In Norfolk farming, forage crops (fodder turnips and red clover) are grown to feed livestock, which absorb nutrients from the soil, and then the feed is fed to livestock, which collect the nutrients in the form of manure. Livestock are kept in barns, so the recovery rate of manure is high. Finally, the manure is used as a raw material to produce compost, which is then fed to the fields for human food production (wheat and barley are grown), thus establishing a nutrient cycle system within the farm. This super-intensive farming method, which maximizes the use of manure as a source of nutrients, has been so revolutionary that it has doubled the production of wheat (for details, see Part 11 of this series).

3. the origin of the Norfolk farming method is the Flemish saying

The Flemish region of mainland Europe (present-day southern Netherlands to western Belgium and northern France), across the river from the birthplace of Norfolk agriculture, has an old saying: "No fodder, no livestock; no livestock, no fertilizer; no fertilizer, no harvest. This saying tells us that compost plays an important role in European crop rotation as a source of nutrients. This is the very starting point of the Norfolk farming method.

There is another important point to be made in this adage. That is, the production of compost as fertilizer requires feed for livestock. As the saying goes, compost cannot be produced as a source of nutrients without producing crops that feed livestock (forage crops), not human food. That is why Norfolk Farming allocated half of the land area on the farm to fodder crop production, and added fodder turnips and red clover to the crop rotation. This increase in forage production increased the number of livestock that could be kept, which in turn greatly increased the amount of manure produced. Thus, it became possible to increase the production of manure as a source of nutrients. The increased production of manure increased the amount of inputs to the farmland, and the amount of nutrients given to the farmers increased. The result was an almost doubling of wheat yields, as already mentioned.

To support this, however, it was necessary to allocate half of the farmland for nutrient source production, i.e., cultivation of forage crops for livestock feed. This was a major land use challenge for the Norfolk farming method, which uses nutrient cycling to maintain soil fertility and sustain high crop production. The land area for human food production is only half of the farmland.

4. land for producing livestock feed is required for compost production using livestock.

How to secure the source of nutrients is an important issue when producing crops on a certain area as organic farming in field crops. It is important to remember that even in field crops, if we try to maintain soil fertility through nutrient cycling using livestock, as in Norfolk farming, labor for livestock rearing and land for livestock feed production are required in the cycle system. The amount of feed produced on the land determines the number of livestock that can be kept on the farm. The number of animals determines the amount of manure produced, which in turn determines the amount of manure produced. As the Flemish saying goes, "Without feed there is no livestock, and without livestock there is no manure.

5. what to do about the increased labor burden of compost production

Even in field crops that do not use livestock, compost as a source of nutrients should be self-sufficient in the nutrient-recycling crop production that organic agriculture aims for, rather than bringing in manure produced outside the cycle system. It is necessary to secure a source of nutrients through the use of green manure and compost production using crop residues. Moreover, to make usable, mature compost, it is necessary to turn the compost around and manage the compost. The labor-intensive nature of compost production is the main reason why farmers engaged in organic farming are reducing the size of their farms (MAFF, 2022). In addition to weeding, another major issue is how to manage the increased labor burden of compost production.

The "Green Food System Strategy" launched by the Ministry of Agriculture, Forestry and Fisheries in May 2021 aims to expand organic farming to 25% of all arable land, or 1 million hectares, by 2050. However, I wonder if they have given much thought to the production of organic fertilizers necessary to supply nutrients to this area. It is highly doubtful.